Description

The Ultipleat® High Flow XL filter is a large diameter, coreless, single open ended, pleated cartridge with an inside to outside flow pattern. The spacing between the pleats within the filter has been optimized to deal with applications with moderate solids loadings. The filter's unique crescent-shaped pleat geometry, combined with its large 6 inch (15.24 mm) diameter and proprietary range of available Pall filter media, allows you to use significantly fewer filters and smaller housings for high flow rate applications.

Benefits

|  |

Specifications

Materials of Construction

| Filter Medium Type | Filter Medium | Support/Drainage Materials | End Caps | Wrap Materials |

|---|---|---|---|---|

| Ultipor® GF | Glass Fiber | Polyester/Nylon | Glass Filled Acetal | Polyester and Polyamide Hotmelt |

Operating Conditions2

| Glass Fiber Medium | |

|---|---|

| Maximum Differential Pressure1 (normal inside to outside flow) |

50 psid at 250°F 3.44 bar at 121°C |

1 For fluids compatible with the filter element at the stated temperature

2 Maximum temperature in aqueous system is 140°F/60°C

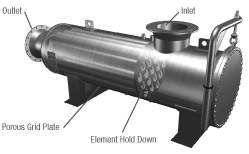

Horizontal Housings

Horizontal Housings, Centerpipe Design

Performance

Housing Design

Three configurations are available: horizontal, vertical and centerpipe design.

The in-line horizontal configuration eliminates the need for a platform, or ladder, to remove the filters from the housing.

Vertical vessels may be more appropriate when floor space is limited. However, a platform may be needed to easily remove the elements.

In both the standard horizontal and vertical configurations, the inlet pipe is located between the filter element tubesheet and housing lid. The larger the vessel diameter, the longer the distance to reach in and remove the elements from the vessel. In a centerpipe vessel the housing lid is closer to the filter tubesheet. When the lid is opened the filters are easily accessible for installation and removal. Centerpipe vessels are larger in diameter, and more costly.

- Designed to the ASME, section VIII, division 1 code

- Maximum differential pressure across tubesheet: 75 psid (5.17 bar) maximum

- Standard housing gasket: spiral wound 304 stainless steel mineral fiber

- Carbon steel exterior surfaces: sandblasted and coated with an inorganic zinc

- Vent and drains: 1 inch FNPT

- Corrosion allowance: 1/8 inch

Housing Ratings

| Vessel Material | Tubesheet and Hold Down Plate Material of Construction | Pressure Rating in Psig/Bar g at 140°F / 60°C |

|---|---|---|

| Carbon steel | 304 stainless steel | 275 psig (18.95 bar) |

| 304 stainless steel | 304 stainless steel | 259 psig (17.85 bar) |

| 304L stainless steel | 304L stainless steel | 216 psig (14.89 bar) |

| 316 stainless steel | 316 stainless steel | 261 psig (17.99 psig) |

| 316L stainless steel | 316L stainless steel | 216 psig (14.89 psig) |

Figure 1: Ultipleat High Flow Horizontal Housings (Aqueous Housing Pressure Drop - PSID)

Type

Related Documents

To install a filter element, remove the element hold down plate by lifting it off the locating pins. Lubricate the O-ring on the open-end of the filter with a compatible fluid, and slide the closed end of the filter into the perforated cage, which is welded to the tubesheet. Seat the elements in place by pressing down on the open-end of the filter until the element is snug in the tubesheet. This provides a seal between the filter and housing via the filter O-ring. The open-end cap must be below the tubesheet surface. After installing all the filter cartridges, reinstall and secure the element hold down plate by guiding it over the locating pins on the tubesheet. The purpose of the hold down plate is to prevent the elements from becoming dislodged in the event of reverse flow.

A filter element tool is provided with each housing to aid with the installation and removal of the filter cartridges. This tool eliminates the need for an operator to reach within the filter vessel to either remove or install filters.

Ordering Information

Ordering Information/Specifications

Filter Cartridge Part Number: HFU

| Code | Filter Dimensions, Inches (nominal) | Suggested Maximum Flow Per Cartridge- GPM/LPM/MGD of Water | |||

|---|---|---|---|---|---|

| 620 | 6" Diameter by 20" Long | 175/663/0.25 | |||

| 640 | 6" Diameter by 40" Long | 350/1325/0.5 | |||

| 660 | 6" Diameter by 60" Long | 500/1900/0.7 | |||

| Medium Type | Code | Absolute Liquid Removal Rating (Microns) at 99.9% Efficiency by Particle Count1 | Element Pressure Drop2 20 inch length (PSID/GPM)/ (MBar/M3/H) | Element Pressure Drop2 40 inch length (PSID/GPM)/ (MBar/M3/H) | Element Pressure Drop2 60 inch length (PSID/GPM)/(MBar/M3/H) |

|---|---|---|---|---|---|

| Ultipor® GF Medium-XL | HGF100 | 10.0 | 0.0029/0.88 | 0.0014/0.425 | 0.001/0.304 |

1 The test procedure used is an adaptation of ISO 4572, modified to determine the micron size above which particles are quantitatively removed.

2 Pressure drop in PSID per GPM for the cartridge length shown. Multiply this value by the total system flow to determine the aqueous pressure drop. Next for fluids other than water, multiply this value by the fluids viscosity at the operating temperature in centipoise. This value is the pressure drop across the Ultipleat High Flow filter(s) only; it must be added to the pressure drop due to the Ultipleat High Flow filter housing.

| Code-Filter O-Ring | Material |

|---|---|

| H13 (Standard for glass fiber filters) | Buna N |

| H13U1 | Buna N U-Cup |

| J (Standard for polypropylene filters) | Ethylene Propylene |

| JU1 | Ethylene Propylene U-Cup |

| H4 | Silicone |

| H | Fluorocarbon Elastomer |

1 U-Cup seal should be deployed in those applications where ease of element removal is of paramount concern.

Ordering Information-Standard Horizontal and Vertical Housings

| Part Number | No. of Filters | Rated Flow Per Housing-GPM/ LPM 60" Long Filter | Nominal Housing Diameter (In/mm) (D) | Inlet/ Outlet Flange Diameter (In/mm) | Maxiumum Horizontal Housing Overall Length (In/mm) (L) |

|---|---|---|---|---|---|

1HF  0804F1 0804F1 |

1 | 500/1893 | 8 5/8 / 219.1 | 4/101.6 | 89/2261 |

2HF  1606F1 1606F1 |

2 | 1000/3785 | 16/406.4 | 6/152.4 | 100/2527 |

3HF  1808F1 1808F1 |

3 | 1500/5680 | 18/457.2 | 8/203.2 | 104/2642 |

4HF  2008F1 2008F1 |

4 | 2000/7570 | 20/508 | 8/203.2 | 105/2654 |

7HF  2412F1 2412F1 |

7 | 3500/13248 | 24/609.6 | 12/304.8 | 112/2832 |

12HF  3016F1 3016F1 |

12 | 6000/22710 | 30/762 | 16/406.4 | 121/3073 |

19HF  3620F1 3620F1 |

19 | 9500/35958 | 36/914.4 | 20/508 | 129/3264 |

| Part Number | Horizontal Housing Height (In/mm) (H) | Distance Between Housing and Lid and Tube- sheet (In/mm) | Housing Weight Empty (Lbs/KG) | Housing Weight Full of Water (Lbs/KG) | Housing Cover Swing Opening (In/mm) |

|---|---|---|---|---|---|

1HF  0804F1 0804F1 |

32/817 | 14.5/368.3 | 471/214 | 621/282 | 9/228.6 |

2HF  1606F1 1606F1 |

40/1023 | 22.7/576.3 | 1172/532 | 1771/803 | 25.77/654.6 |

3HF  1808F1 1808F1 |

43/1093 | 26.2/665.2 | 1583/718 | 2384/1081 | 27.28/692.8 |

4HF  2008F1 2008F1 |

46/1175 | 26.38/669.6 | 2087/947 | 3048/1382 | 29.77/756.3 |

7HF  2412F1 2412F1 |

59/1487 | 31.88/809.6 | 3250/1474 | 4762/2160 | 34.28/870.6 |

12HF  3016F1 3016F1 |

58/1480 | 38.69/982.7 | 4670/2118 | 7306/3314 | 37.99/964.9 |

19HF  3620F1 3620F1 |

68/1718 | 43.37/1101.6 | 7060/3202 | 11121/5045 | 44.83/1138.8 |

Ordering Information - Horizontal Orientation, Centerpipe Designed Housings

| Part Number | No. of Filters | Rated Flow Per Housing-GPM/ LPM 60" Long Filter | Nominal Housing Diameter (In/mm) (D) | Inlet/ Outlet Flange Diameter (In/mm) | Maximum Horizontal Housing Overall Length (In/mm) (L) |

|---|---|---|---|---|---|

7HF 2808F1 2808F1 |

7 | 3500/13248 | 28/711 | 8/203.2 | 104.3/2648 |

8HF 3012F1 3012F1 |

8 | 4000/15140 | 30/762 | 12/304 | 117.6/2988 |

| Part Number | Horizontal Housing Height (In/mm) (H) | Distance Between Housing and Lid and Tube- sheet (In/mm) | Housing Weight Empty (Lbs/KG) | Housing Weight Full of Water (Lbs/KG) | Housing Cover Swing Opening (In/mm) |

|---|---|---|---|---|---|

7HF 2808F1 2808F1 |

57/1448 | 4.9/124 | 4056/1840 | 6229/2825 | 36/914 |

8HF 3012F1 3012F1 |

58 1/4 / 1480 | 6.1/154 | 4707/2135 | 7348/3333 | 40.06/1018 |

| Code | Housing Configuration |

|---|---|

| H | Horizontal |

| V | Vertical |

Code  | Nominal Cartridge Length (Inches/mm) |

|---|---|

| 2 | 20/508 |

| 4 | 40/1016 |

| 6 | 60/1524 |

| Code | Housing Metallurgy |

|---|---|

| 285 | Carbon Steel Vessel, 304 Stainless Steel Tubesheet |

| S3 | 304L Stainless Steel |

| S8 | 304 Stainless Steel |

| L3 | 316L Stainless Steel |

| L8 | 316 Stainless Steel |

| Code | Optional Outlet Style Horizontal Housings |

|---|---|

| XU | Upper Outlet Location |

| XL | Lower Outlet Location |

Reviews

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.