Description

Cylindrical Membralox®

Ceramic Membranes

Type EC0760 and EC1935

Cylindrical Membralox ceramic elements feature the same exceptional performance, mechanical and chemical resistance and service life as the well-recognized Membralox product range.

These membrane geometries are intended to be compatible with a wide range of filter suppliers housing designs.

Membralox membranes are the key components of crossflow systems used in numerous food and beverage applications, such as clarification / concentration / purification of fermentation broths,dextrose syrups, fruits juices, dairy products, etc.

Description

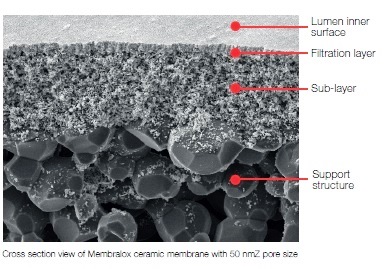

These Membralox ceramic elements are asymmetric multi-channel membranes composed of a porous alumina support supporting filtering layers casted on the inner surface of the lumens.

Pall Membralox membranes are made from high purity ceramic oxides in multiple geometries.

All along the manufacturing, a stringent quality control process verifies consistency of membrane characteristics versus precise acceptation criteria to deliver reproducible membrane performances, batch after batch, years after years.

Prior to release, Membralox membranes are 100% bubble point tested to confirm filtration layer and end sealing integrity.

| Features | Benefits |

| Highly asymmetric structure with 12 μm average support pore size | High permeability for better permeate flux and performances |

| Support structure based on alpha- Alumina with exceptional purity | Wide chemical and pH compatibility (0-14) |

| Very high support sintering temperature coupled with recrystallization process | Exceptional mechanical resistance. Excellent thermal stability |

| Proprietary alpha-Alumina endsealing | Long term resistance to corrosion. Permanent protection against product leakage |

| Sharp pore size distribution | Optimum filtration performance and selectivity |

| Final 100% bubble point testing | Filtration layer integrity |

| Stringent quality control process and procedures with full traceability | Reproducibility, Reliability, Durability. Extremely low failure rate in operation |

Specifications

Materials of construction

| Components | Description |

| Support structure | High purity α-alumina |

| Filtering layers (depending on pore size) |

High purity α-alumina and/or zirconia |

| End sealing | High purity α-alumina |

Technical Information

Multichannel Element Characteristics

| EC1935 | EC0760 | |

| Channel diameter1 | 3.5 mm | 6.0 mm |

| Number of Channel | 19 | 7 |

| Filtration surface area | 0.25m2(2.6ft2) | 0.16m2(1.67ft2) |

| Length | 1178 mm (3.86 ft) | 1178 mm (3.86 ft) |

Membrane Characteristics

| Pore Sizes2,3 | Membrane Material | |

| Microfiltration | 0.8, 0.5, 0.2 μm | Alpha-alumina |

| Ultrafiltration | 100, 50 nm | Zirconia |

The 12 μm pore size ceramic support of Membralox membranes is made of high purity alpha-alumina.

2as measured by Pall proprietary permeametry method

3other pore sizes available on request

Food Contact Compliance

Please refer to the Pall website for a Declaration of Compliance to specific National Legislation and/or Regional Regulatory requirements for food contact use.

Performance

Quality

-

- Manufactured under an ISO 9001:2008 certified Quality Management System

Type

Ordering Information

Ordering Information

This information is a guide to the simplified designation structure and possible options.

For availability of specific options, please contact Pall.

Example Part Number: EC1935/1178/100nmZ

(Refer to bold references in the tables below)

Part Number: EC <Code from TABLE 1> /1178/ <Code from TABLE 2>

Table 1:Multichannel Element Type

| Code | Description |

| 1935 | 19 channels 3.5 mm |

| 0760 | 7 channels 6.0 mm |

Table 2:Multichannel Pore Size

| Code | Description |

| 0.8μA | Alumina 0.8 μm microfiltration layer |

| 0.5μA | Alumina 0.5 μm microfiltration layer |

| 0.2μA | Alumina 0.2 μm microfiltration layer |

| 100nmZ | Zirconia 100 nm ultrafiltration layer |

| 50nmZ | Zirconia 50 nm ultrafiltration layer |

Reviews

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.