Description

Pall Corporation has designed the OenoClear cartridges for the wine industry as a complete, reliable and economical alternative to sheet (pad) filtration. A fully enclosed hygienic cartridge filtration assembly can be utilized in applications such as final clarification, pre-filtration and yeast removal in wine processing. Having been specifically engineered for the wine industry, OenoClear cartridges incorporate a unique, polyaramid membrane in a single open ended (SOE) AB style cartridge to fit in a sanitary housing to ensure complete yeast removal and allow repeated regeneration in situ. This combination of efficient yeast removal and extended service life enable OenoClear filters to replace sheet filtration, offering improved performance and better economics.

Features

- Long service life - excellent economics

- Intrinsically water wettable

- Fixed pores, non-shedding

- Resin and surfactant –free

- Flushed with high purity water

- Fully enclosed system for hygienic operation

- Low holdup volume for minimum product losses

- Can maintain performance under pulsed flow conditions

- Performance not operator dependent

- High area for long life

- Can enhance final filter life

- Simple cleaning to increase life

- Hot water sanitizable

- Repeatedly steamable in situ

- Individually serialized

- ISO 9000 Certified Quality System

- Manufactured in a controlled environment

- Available as an automated system

Specifications

Food Contact Compliance

- Food contact compliant filters are available. Please consult the Declarations of Compliance for applicable part numbers at the links below.

- Please refer to the Pall website foodandbev for a Declaration of Compliance to specific National Legislation and/or Regional Regulatory requirements for food contact use.

Materials of Construction

- FDA-Listed materials per 21 CFR

- Membrane: Polyaramid (on cellulose substrate)

- Support and Drainage Layers: Polyester

- Endcaps, Cage, and Core: Polypropylene

- O-rings: Silicone1

Removal Ratings

- An alternative to sheet filters typically referred to as 0.2 µm nominal

- Typical Saccharomyces cerevisiae TR is > 109

- Typical Oenococcus oeni TR is > 106

Dimensions (Nominal)

- Lengths: 510 mm (20 in.), 760 mm (30 in.), 1015 mm (40 in.)

Configuration (AB Code 7)

- Adapter: Double 226 O-ring

- Finned end, bayonet lock

Biological Safety

- All materials are listed in Title 21 of the US Code of Federal Regulations

Operating Conditions2

- Maximum Operating Pressure (forward): 60 psid (4 bard) at 80 °C (176 °F)

- Maximum Reverse Pressure: 7 psi (500 mbar) at 20 º C (68 °F)

Autoclave/Steaming In Situ

- Autoclaveable or Steamable in situ

- Cumulative Steam Exposure3: 25 hrs at 121 °C (250 °F)

Sanitization/Cleaning3

- Hot Water Cumulative Exposure: 50 hours at 85 ºC (185 °F)

- Peroxyacetic Acid (300 ppm) Cumulative Exposure: 50 hours

- Alkaline hypochlorite (300 ppm) Cumulative Exposure: 50 hours

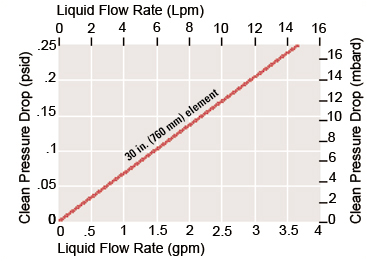

Pressure Drop vs. Liquid Flow Rate4

1Other polymers available.

2Using compatible liquids.

3Lab tests establish multi-cycle resistance; filters should be qualified in actual use. Cool to ambient temperature before use.

Contact Pall for recommended procedures.

4Typical initial clean media ΔP per 30 in. (760 mm) element for water at 68°F (20°C); viscosity 1 centipoise. For 20 in. (508 mm) and 40 in. (1016 mm) configurations, divide the differential pressure by 0.67 and 1.33 respectively. For assistance in filter assembly sizing and housing selection, contact your local Pall Distributor or Pall Corporation directly.

Type

Filter Cartridges

Ordering Information

| Part Number5 | Length6 |

| AB2SR7WH4 | 510 mm (20 in.) |

| AB3SR7WH4 | 760 mm (30 in.) |

| AB4SR7WH4 | 1015 mm (40 in.) |

5W indicates optimized and qualified for Food and Beverage use.

H4 suffix = Silicone O-rings (standard).

Alternate O-rings are available.

6Dimensions are nominal

Reviews

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.