Description

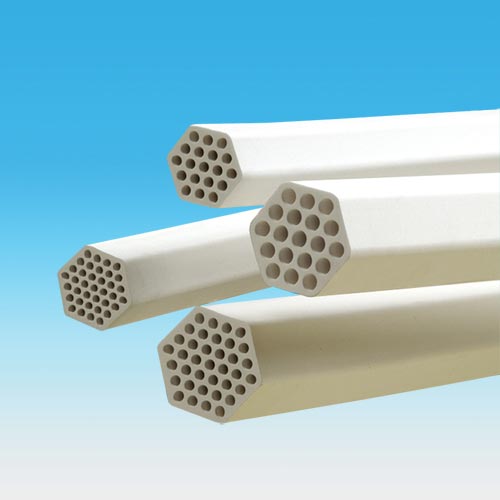

Pall Membralox ceramic membranes are asymmetric multi-channel membranes composed of a porous alumina support and a filtering layer (alumina, zirconia, titania).

High compactness of the multichannel membrane combined with high permeability allows the treatement of large volumes with high throughput.

The Membralox GP ceramic membranes range with longitudinal permeability gradient, ensure an homogeneous and calibrated flux along the flow channel, thus optimum utilization of membrane surface within a stable microfiltration regime.

Membralox filtration modules are the key element in process reliability.

High compactness of the multichannel membrane combined with high permeability allows the treatement of large volumes with high throughput.

The Membralox GP ceramic membranes range with longitudinal permeability gradient, ensure an homogeneous and calibrated flux along the flow channel, thus optimum utilization of membrane surface within a stable microfiltration regime.

Key Features

- High flux

- Wide chemical and pH (0-14) compatibility

- Excellent thermal stability

- Long term and reliable performance

- Sanitizable and sterilizable

- Ability to withstand high frequency backpulsing cycles

- 100% bubble point integrity tested during manufacturing

- Suited for high fouling fluids, viscous products, high concentration factors, fine filtration, diafiltration, automatic and easy cleaning in place (CIP)

- Meets the requirements for food usage1

Pall Membralox Membranes Quality

- Unique ceramic support of the 12 μm pore size allows the highest flux.

- Patented alumina end-sealing provides superior resistance to corrosion and cleaning cycles.

- High homogeneity and quality of the filtration layers for optimum filtration performances and selectivity.

- Exceptional mechanical resistance for long service life

Widest Separation Range

The exceptional structure of Membralox filtering elements has enabled the development of the widest range of micro and ultrafiltration ceramic membranes. A complete range of modules helps for scale-up from laboratory separations to full size industrial needs.Cost Effective Separations

The superior characteristics of Pall Membralox ceramic membranes provide economical solutions for high added value macro-molecule concentration, effluent recycling or reduction and difficult fluid clarification.Membralox filtration modules are the key element in process reliability.

Specifications

Membralox ceramic membranes

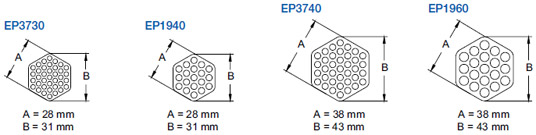

| EP37302 | EP3740 | EP19402 | EP1960 | |

| Channel Diameter (mm) | 3 | 4 | 4 | 6 |

| Number of channels | 37 | 37 | 19 | 19 |

| Filtration surface area (m2) | 0.35 | 0.47 | 0.24 | 0.36 |

| Length (mm) | 1020 | 1020 | 1020 | 1020 |

Membralox membrane pore sizes

| Microfiltration | 1.42, 0.82, 0.5, 0.2, 0.12 μm | α-alumina |

| Ultrafiltration | 100, 50, 20 nm | zirconia |

Some pore sizes are not available on all support geometries.

Please contact Pall for further information

Operating limits of Membralox modules in liquids filtration3

| Temperature | 95 ºC (203 °F) |

| Pressure | 10 bar 4 (145.1 psi) |

Membralox HCB modules

| Module Type | No. of Membranes | Membrane Type | Surface Area (m2) | Retentate Connections (RC) Permeate Connections (PC) |

| M-19P3740 | 19 | EP3740 | 8.87 | RC: Weldable flanges/O-ring gaskets |

| M-19P1960 | EP1960 | 6.84 | PC: Weldable flanges/ flat gaskets | |

| M-36P3740 | 36 | EP3740 | 16.81 | RC: Weldable flanges/O-ring gaskets |

| M-36P1960 | EP1960 | 12.96 | PC: Weldable flanges/ flat gaskets | |

| M-60P3730 | 60 | EP3730 | 21 | RC: Weldable flanges/O-ring gaskets |

| M-60P1940 | EP1940 | 14.40 | PC: Weldable flanges/ flat gaskets | |

Membralox HCS 3-A modules

| Module Type | No. of Membranes | Membrane Type | Surface Area (m2) | Retentate Connections (RC) Permeate Connections (PC) |

| M-36P3740 | 36 | EP3740 | 16.81 | RC: Weldable flanges/O-ring gaskets |

| M-36P1960 | EP1960 | 13 | PC: Weldable ferrules / 3-A gaskets | |

| M-60P3730 | 60 | EP3730 | 21 | RC: Weldable flanges/O-ring gaskets |

| M-60P1940 | EP1940 | 14.40 | PC: Weldable ferrules / 3-A gaskets | |

Membralox SD 3-A modules

| Module Type | No. of Membranes | Membrane Type | Surface Area (m2) | Retentate Connections (RC) Permeate Connections (PC) |

| M-1P3730 | 1 | EP3730 | 0.35 | RC: Weldable collars/ 3-A gaskets |

| M-1P1940 | EP1940 | 0.24 | PC: Weldable ferrules/ 3-A gaskets | |

| M-1P3740 | EP3740 | 0.47 | ||

| M-1P1960 | EP1960 | 0.36 | ||

| M-3P3730 | 3 | EP3730 | 1.05 | RC: Weldable collars/ 3-A gaskets |

| M-3P1940 | EP1940 | 0.72 | PC: Weldable ferrules/ 3-A gaskets | |

| M-3P3740 | EP3740 | 1.40 | ||

| M-3P1960 | EP1960 | 1.08 | ||

| M-7P3730 | 7 | EP3730 | 2.45 | RC: Weldable collars/ 3-A gaskets |

| M-7P1940 | EP1940 | 1.68 | PC: Weldable ferrules/ 3-A gaskets | |

| M-12P3740 | 12 | EP3740 | 5.60 | RC: Weldable collars/ 3-A gaskets |

| M-12P1960 | EP1960 | 4.32 | PC: Weldable ferrules/ 3-A gaskets | |

| M-19P3730 | 19 | EP3730 | 6.65 | RC: Weldable collars/ 3-A gaskets |

| M-19P1940 | EP1940 | 4.56 | PC: Weldable ferrules/ 3-A gaskets | |

| M-22P3740 | 22 | EP3740 | 10.27 | RC: Weldable flanges/ 3-A gaskets |

| M-22P1960 | EP1960 | 7.92 | PC: Weldable ferrules/ 3-A gaskets | |

| M-37P3730 | 37 | EP3730 | 12.95 | RC: Weldable flanges/ 3-A gaskets |

| M-37P1940 | EP1940 | 8.88 | PC: Weldable ferrules/ 3-A gaskets | |

1 The membranes based on high purity alumia are certified for use in contact with food fluids by Commission Directive 2005/31/EC. All membrane components are made from materials that our suppliers state meet the requirements for food contact use: Alumina and titania are GRAS. Zirconia layers on alumina support are listed in 21 CFR Sect.177.2910.

2 Available in the Membralox GP membrane version. 0.8μm and 1.4μm are available in a double layer version.

3 Any liquids belonging to group II from PED 97/23/EC art 9 - § 2.2

4 1 bar = 100 kPa

Applications

Clarification, concentration and fractionation of:

- Milk and dairy products

- Sugar and sweeteners

- Food ingredients and additives

- Beverages and potable water

- Biological molecules

- Process water and waste streams, in chemical, oil and gas, petrochemical and nuclear industries

- Acids, bases and solvents

Type

Ceramic Filters

Use

Recycling

Additional Information

The limits of use of Membralox modules are determined mainly by the type of housing or gasket materials employed. Based on valuable pilot test data, our Scientific and Laboratory Services can provide advice in selecting the best membrane and module configuration to match your process requirements.

Reviews

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.