Description

Accepts 25.4 cm (10 in.) or 50.8 cm (20 in.)

Nominal Length 1000 Style Filter Cartridges

- Fail-safe cartridge sealing device provides pre-closure assurance of no fluid bypass

- In-line inlet and outlet connections ensure easy installation

- NPT and flange options available

- High pressure models available for applications up to 69 bar (1000 psig) @ 121 °C (250 °F)

Specifications

Housing Specifications

Maximum Operating Pressure

- Standard: 17.2 bar (250 psig) @ 121 °C (250 °F)

- H: 51.7 bar (750 psig) @ 121 °C (250 °F)

- V: 68.9 bar (1000 psig) @ 121 °C (250 °F)

Materials of construction

- 316 stainless steel - wetted parts

Connections

- Inlet/Outlet: 3⁄4 in. NPT

- Drain: 1⁄4 in. NPT

Shell O-rings

- FEP encapsulated fluorocarbon elastomer, silicone elastomer, fluorocarbon elastomer, nitrile, ethylene propylene

Eye nut option

- Eye nuts can be substituted for standard hex nuts. Order Part T10640030. Eye nuts are standard with flanged units.

Flange option

- 150 lb., 300 lb., or 600 lb. ANSI raised face 3⁄4 in. flanges are available.

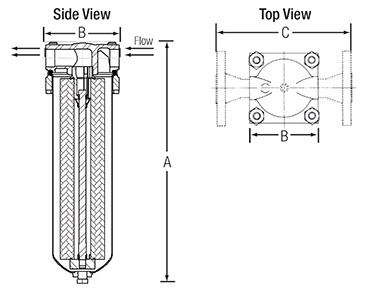

Dimensional Data (nominal)

| Model | Liquid1 Flow Rate lpm (gpm) |

Gas2 Flow Rate scfm |

Dimensions cm (in.) | Weight Empty | |||

| A | B | C | Threaded Nozzle kg (lb) |

Flanged Nozzle kg (lb) |

|||

| LMO11 | to 37.9 (10) | 125 | 33 (13) | 11.1 (4.375) | 21.6 (8.5) | 4.1 (9) | 5.9 |

| LMO12 | to 75.7 (20) | 225 | 58.4 (23) | 11.1 (4.375) | 21.6 8.5) | 5.9 (13) | 7.7 (17) |

| LMO11H | to 37.9 (10) | 125 | 33 (13) | 11.1 (4.375) | 22.5 (8.875) | 4.1 (9) | 7.7 (17) |

| LMO12H | to 75.7 (20) | 225 | 58.4 (23) | 11.1 (4.375) | 22.5 (8.875) | 5.9 (13) | 9.5 (21) |

| LMO11V | to 37.9 (10) | 125 | 33 (13) | 11.1 (4.375) | 23.8 (9.375) | 4.1 (9) | 9.5 (21) |

| LMO12V | to 75.7 (20) | 225 | 58.4 (23) | 11.1 (4.375) | 23.8 (9.375) | 5.9 (13) | 11.3 (25) |

1 Dependent upon cartridge selection, fluid viscosity and allowable pressure drop.

2 Housing pressure drop less than 0.07 bar (1 psig).

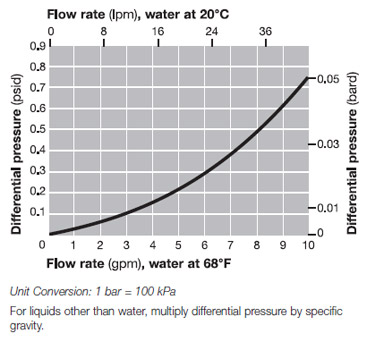

Performance

Housing Differential Pressure vs. Liquid Flow Rate

Unit Conversion: 1 bar = 100 kPa

For liquids other than water, multiply differential pressure by specific gravity.

Type

Housings, Vessels, or Assemblies

Ordering Information

Pall Part Number = LMO1 [1] [2] GN [3] [4]

Table 1

| Code | Bowl nominal lengths (cm/in.) |

| 1 | 25.4/10 |

| 2 | 50.8/20 |

Table 2

| Code | Pressure ratings |

| Blank | 17.2 bar (250 psig) @ 121 °C (250 °F) |

| H | 51.7 bar (750 psig) @ 121 °C (250 °F) |

| V | 68.9 bar (1000 psig) @ 121 °C (250 °F) |

Table 3

| Code | Inlet/outlet size |

| 12 | 3⁄4 in. NPT |

| 13 | 3⁄4 in. Flange |

Table 4

| Code | Seal materials |

| H | Fluorocarbon elastomer |

| H1 | FEP encapsulated fluorocarbon elastomer |

| H4 | Silicone |

| H13 | Nitrile |

| J | EPDM |

Reviews

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.