The Window to Your Fluid System's Health

Airline engineers and mechanics want to know the condition of the system fluid and to receive advance warning of any impending component failure.The Dirt Alert diagnostic layer provides a simple way of viewing and analysing the debris captured by the main system filter element. It can assist operators in preventative maintenance, both during flight and on the ground during "Green Run" testing.

How Does it Work?

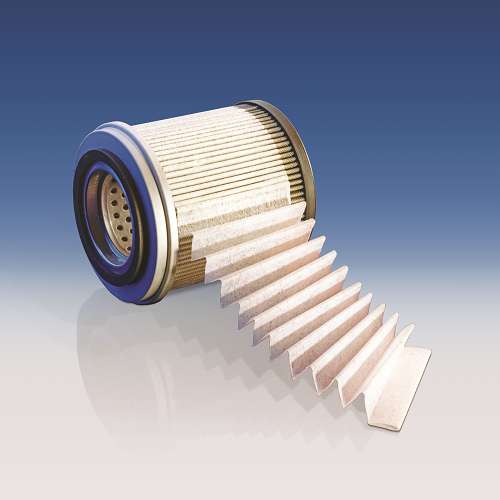

The 'Dirt Alert' element incorporates a pull-out diagnostic layer of porous medium in conjunction with regular filtration medium. The diagnostic layer can be removed after a certain period in service, or after engine flushing.The diagnostic layer can be immediately examined on site to observe if there are any large wear debris particles present. If there is any contamination present, this can then be analysed in a number of ways, such as microscopic examination, chemical analysis etc. After the 'Dirt Alert' layer has been removed it can be retained as part of the maintenance record.

Pall's Dirt Alert filter elements are used in

- Engine Lube Systems

- Helicopter Transmission Lube systems

Civil engine Green Run applications include CFM56 series, JT8D, PW2000, PW4000, PW6000, and GTF™

Literature and Other Resources

Condition monitoring of aerospace hydraulic and lubrication systems via filter debris analysis.

Each product is designed and tailored to meet the customer specification requirements. If you have an aerospace application that needs a diagnostic filter element, please talk to one of our experts Contact Aerospace.

For commercial aircraft products, please contact our authorised distributor Satair.

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.