Optimized designs using our knowledge of Fuel, Lube and Hydraulic, and Liquid Coolant filtration systems

- Compact packaging and low weight

- High Reliability

- Qualified using in-house test facilities

- OEM approved

Maintaining a specified level of fluid cleanliness is critical to the operation and reliability of aerospace fluid systems and equipment.

A filter assembly consists of a filter housing and a high-performance filter element. Where specified, it can include bypass valves, non-return valves, differential pressure monitoring devices, and other sampling points.

Features

- Incorporates high performance filter elements using Pall proprietary media

- High-strength construction

- Filter Bowl & Filter Head meet fatigue and pressure requirements (dependant on application)

- Low differential pressure

- Bowl-locking mechanism to prevent filter bowl loosening under vibration in service

- Electro-Static Discharge (ESD) pin

Benefits

- Light-weight designs

- Small space envelope

- Improved system performance and reliability

- Qualified to stringent OEM requirements

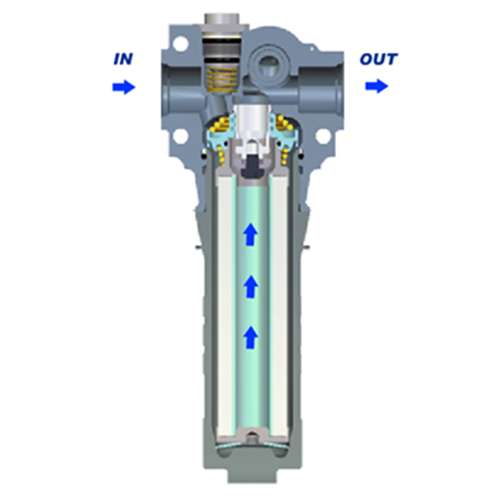

Aerospace filter assembly cross-section

The system fluid enters the assembly through the inlet port. It flows through the inlet and into the filter element.

- Filter Element

Particulate contamination including metals, dust, fibers, seal material, etc., is removed and captured by the filter element. The clean fluid then exits the assembly through the outlet port. - Electro-Static Discharge (ESD) pin

Some fuel filter elements include Pall’s patented ESD pin. This feature dissipates any charge build-up and prevents component damage due to electrostatic discharge.

Click for more information on Electro-Static Discharge (ESD) in industrial systems - Monitoring Devices/Sensors

After a period of service, the element will become loaded with contamination and require replacement. The Differential Pressure Indicator/Switch (DPI/DPS) located in the head of the filter assembly indicates when the filter element is becoming plugged with contamination and needs to be changed.

A thermal lockout device (optional) prevents false indication at cold start conditions. - Bypass Valve

If the element is not changed, the filter element differential pressure will continue to rise. Above a certain value, the bypass valve opens and the fluid by-passes the filter element and passes directly to the outlet port. - Shut-Off Diaphragm (optional)

This prevents loss of fluid during element change-out.

Pall’s filter assemblies are qualified for a wide variety of systems:

- Engine Lube

- Engine Fuel

- Hydraulic

- Helicopter Gearbox Transmissions

- Radar Cooling

- Liquid Coolant Systems

We have decades of experience providing filtration solutions for commercial and military aerospace programmes. Each design is unique to the application – below are a few examples of the wide range of filter assemblies that Pall has qualified.

|

|

|

Literature and Other Resources

Mi8, 17, 24/35 Helicopters: Improving Reliability and Availability

Do you want to know more about Aerospace Filtration? We can help Watch our Filtration 101 webinar to learn about

- How to increase system reliability

- Typical reasons for component failure

- Importance of fluid cleanliness

- How to correctly specify a filter

- How filters are tested to demonstrate their performance

- And more…

Our filter assemblies are designed and tailored to meet the customer specification requirements.

If you have an aerospace application that needs a high performance filter assembly, please talk to one of our experts Contact Aerospace

For commercial aircraft products, please contact our authorised distributor, Satair

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.