Last Chance Filters (LCFs)

Last Chance Filters provide point-of-use component protection and help to prevent sudden, catastrophic failure in fluid systems

They are installed immediately upstream of sensitive or critical components (e.g. nozzles, valves) and are designed to supplement the main system filters.

Features

Benefits

|   |

How Does it Work?

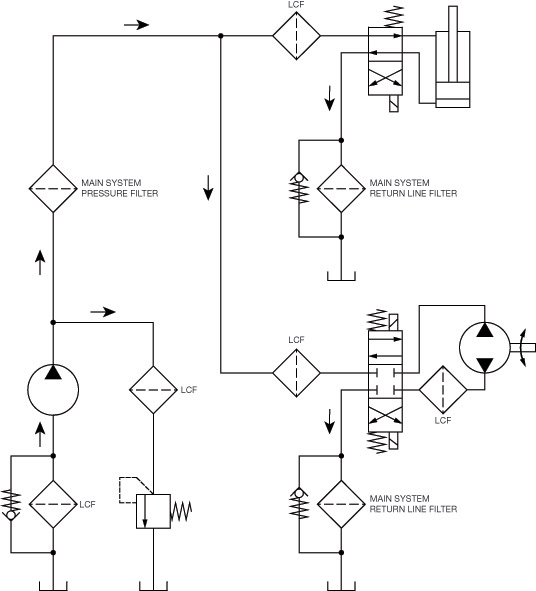

Even though the main system filter may be very effective, there can still be large particulate contamination generated within the fluid system, downstream of the main filter, e.g. built-in contaminants, break-in wear debris, servicing and maintenance contamination.

The secondary, Last Chance Filters, trap particles such as machining chips, burrs, seal material, wear particles and fluid breakdown products.

In general, there are four conditions when a Last Chance Filter should be considered by the system designer:

- Components related to flight safety

- Components downstream from known sources of large particles

- Dead-end components or those not flushed during actuation

- Components with orifice diameters of 1⁄12 in. (2mm) or less

Typical Locations

A Last Chance Filter can be installed in one or more of these places in a system:

- Immediately upstream of the component to be protected.

- Inside the component, as an integral part of the assembly.

- At the normal outlet of a contamination-vulnerable component that experiences reverse flow.

Example Installations

|  |  |

| Swaged In | Connecting Bobbin | Tri-Dot Union mounted |

|  |  |

| Disc Manifold | Port Boss | Screensert |

| ||

| In-Pipe |

Note: special handling precautions must be taken on opening the package to ensure that the minimum of contamination is introduced.

Pall's Last Chance Filters provide fluid system protection for a wide variety of applications………

- Engine Lube & Fuel Systems

- Hydraulic Systems

- Helicopter Transmission Lube systems

- Avionics (E/E) Cooling systems

Photo Courtesy of the U.S. Army. |

|

For more information, contact your local Pall sales representative or e-mail: aerospace@pall.com

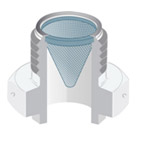

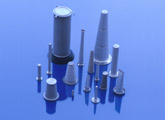

Last Chance Filter discs are available in a wide range of shapes and sizes.

For more information, contact your local Pall sales representative or e-mail: aerospace@pall.com

| USA Part Numbers | European Part Numbers | ||

| DISC / MESH FORMS |  |

20001-*-* 20020-*-* 21041-*-*-* 21042-*-*-* 22000-*-* 25587-*-* 26061-*-* 27386-*-*-* 2CR0364 3CR0442 3CR0662 |

QA10200 QA2118 QA10200 |

|

FLANGE MOUNTED FILTERS |

|

20666-*-* 21496-*-*-* 21623-*-*-* 21888-*-* 25274-*-* 25656-*-* 25972-*-* 26327-*-*-*-* 26360-*-*-*-* 2CR6538 3CR0682 3CR0692 |

QA03136-3165 QA03675-3704 QA03532 QA08121 QA11250 QA11270 |

|

FILTER FITTINGS includes ScreensertTM and Tri-DotTM |

|

20011-*-* 20030-*-* 20065-*-* 20261SL-*-* 20535-*-*-* 20549-*-* 20575-*-* 20576-*-* 20601-12-* 20934-*-* 20935-*-*-* 21243-*-* 25692-*-*-* 2CR7445 3CR0295 3CR0317 3CR0318 3CR0438 3CR0570 3CR0627 3CR0746 3CR0757 30799 3CR0805 30868FF-*-*-* |

QA03392 QA04120-4140 QA05990 QA06045 QA06454 QA06998 QA07295 QA07312 QA07415 QA07978 QA08189 |

| FILTER ASSEMBLIES |  |

2CR2086 2CR2103 2CR8936 3CR0167 3CR0453 3CR0475 3CR0556 30866FA[G] |

QA03947 QA07977 |

| WASH FLOW FILTERS |  |

2CR8224 2CR8534 2CR9076 2CR9242 3CR0288 3CR0482 |

|

| LASER DRILLED LCFs |  |

Parts beginning 2CR or 3CR or 31000 |

|

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.