Manufacturing is done completely in-house, including the production of the metal fibers, the formulation of the proprietary base medium, and the design of the element. The process concludes with Pall's scientifically controlled sintering process.

The sintering process fuses the structure of the filter media, insuring a “weld-bond” which utilizes no “binders” that might otherwise shed and contaminate downstream equipment and/or final product quality.

Produced from fine metal fibers ranging from 2 to 38 μm in diameter, the resulting filtration medium exhibits high-efficiency particulate capture and low flow resistance characteristics.

Gaseous service filter cartridge configurations are available in point-of-use designs (i.e. cleaned off-line), or as self-cleaning elements (i.e. blowback filters).

Advantages of Dynalloy Medium:

Resistant in high-temperature and/or corrosive environments- Sintered medium design guarantees a fixed pore structure, resulting in quantitative solids separation and superior effluent quality

- Uniform pore distribution produces a barrier medium that exhibits low flow resistant characteristics and high void volume

- Flame-arresting characteristics provide a high level of safety in handling pyrophoric or explosion-prone powders

Performance Specifications

Standard filter grades

Standard filter grades7 μm and up

Maximum differential pressure

128 bard (1850

Maximum operating temperature

330°C (626°F)

Product Specifications

Standard materials of construction304, 304L, 316, 316L

Standard Dimensions (nominal)

Outside Diameters: 1.375” – 2.75”

Lengths: 26 inch (66 cm) Sections

Typical Applications

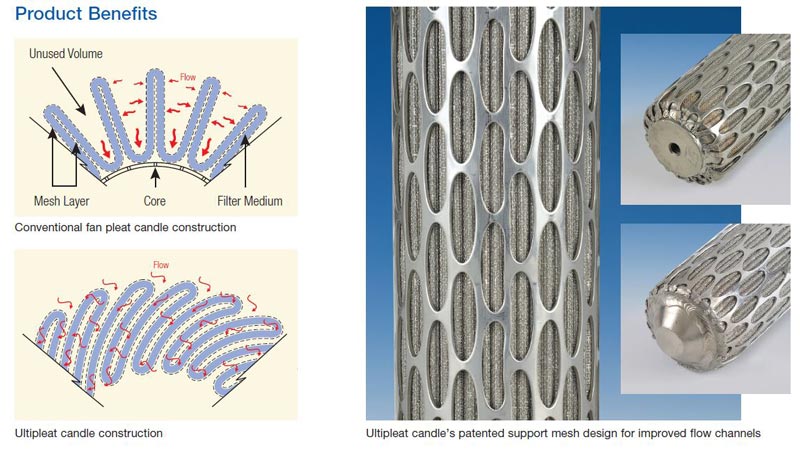

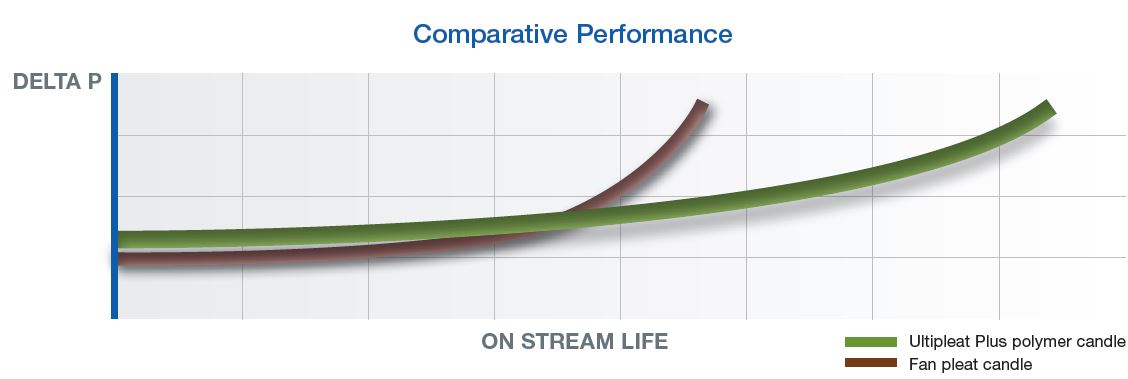

Ultipleat Plus candles are recommended for polymer melt applications where fine filtration is required and where an increase in on-stream life is desired. They are also beneficial for applications where a lower residence time and/or a smaller residence time distribution is needed. Ultipleat Plus candles can be used with a variety of polymers, including, but not limited to:

- Polyester (PET)

- Carbon Fiber Precursor (PAN)

- Nylon (PA 6, PA6,6, etc.)

- Recycled Polymers (rPET, etc.)

- Polyurethane

- And many more!

| Features | Advantages | Benefits |

| Laid Over Pleat |

|

|

| Layered Construction |

|

|

Materials of Construction

316/316L SST; 310 SST; Inconel4 600; Hastelloy5 X; Hastelloy5 C-2000; Haynes5 HR-1605

4 Inconel is a registered trademark of Special Metals Corporation.

5 Hastelloy, Haynes, and HR-160 are registered trademarks of Haynes International, Inc.

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.