The Emflon filter is recommended for chemicals which are compatible with PTFE and polypropylene.

- Wide range of configurations

- Five removal ratings

- High flow rates

- Integrity testable

- Low extractables

- Optimized design

- Manufactured in a cleanroom environment

- 100% integrity tested

Materials

- Medium: PTFE

- Core, cage, and end caps:

Polypropylene - Support and drainage: Polypropylene

- O-ring options: fluorocarbon elastomer1 and Teflon

encapsulated fluorocarbon elastomer

1fluorocarbon elastomer and Teflon are trademarks of DuPont Dow Elastomers

Removal Ratings

- 5.0 μm, 1.0 μm, 0.2 μm, 0.1 μm,

0.05 μm

Filter Areas

- 10" / 254 mm: 9.45 ft2 / 0.88 m2

- 20" / 508 mm: 18.90 ft2 / 1.76 m2

- 30" / 762 mm: 28.35 ft2 / 2.64 m2

- 40" / 1016 mm: 37.80 ft2 / 3.52 m2

Configurations

- Nominal length: 10" / 254 mm,

20" / 508 mm, 30" / 762 mm, and

40" / 1016 mm - Diameter: 2.75" / 70 mm

- O-ring size / end caps:

Code 3 (222 double O-ring / flat end)

Code 8 (222 double O-ring / finned end)

Code 7 (226 double O-ring bayonet lock / finned end)

Operating Conditions

- Maximum Operating Temperature:

194°F / 90°C - Maximum Forward Differential Pressure:

80 psid @ 120°F / 5.5 bar @ 50°C;

50 psid @ 121° - 195°F / 3.5 bar @ 51°- 90°C

Integrity Test Values2

- Per 10" / 254 mm segment

- 0.05 μm: ‹ 45 mL / min @ 35 psig / 2.4 bar

- 0.1 μm: ‹ 64 mL / min @ 19 psig / 1.3 bar

- 0.2 μm: ‹ 32 mL / min @ 11 psig / 0.76 bar

2Test fluid used is 60:40, IPA:H2O.

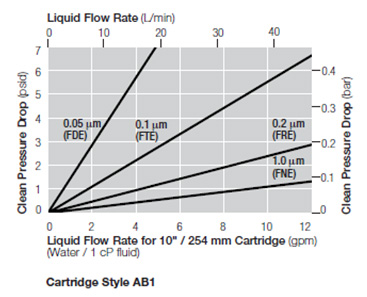

Pressure Drop vs. Liquid Flow Rate 3

3 For liquids with viscosity differing from water, multiply the pressure drop by the viscosity in centipoise.

Filter Cartridges

| Part Number4 | Removal rating (μm) | Nominal Length (in / mm) | Configuration Code | O-Ring Material5 |

| AB1FC8EJ | 5.0 | 10 / 254 | 8 | Ethylene Propylene |

| AB1FN3EH1 | 1.0 | 10 / 254 | 3 | Teflon Encapsulated fluorocarbon elastomer |

| AB1FN3EHF | 1.0 | 10 / 254 | 3 | fluorocarbon elastomer A |

| AB1FR3EH1 | 0.2 | 10 / 254 | 3 | Teflon Encapsulated fluorocarbon elastomer |

| AB1FR3EHF | 0.2 | 10 / 254 | 3 | fluorocarbon elastomer A |

| AB1FR7EH1 | 0.2 | 10 / 254 | 7 | Teflon Encapsulated fluorocarbon elastomer |

| AB1FR8EH1 | 0.2 | 10 / 254 | 8 | Teflon Encapsulated fluorocarbon elastomer |

| AB1FR8EHF | 0.2 | 0.2 | 8 | fluorocarbon elastomer A |

| AB2FR3EH1 | 0.2 | 20 / 508 | 3 | Teflon Encapsulated fluorocarbon elastomer |

| AB2FR3EHF | 0.2 | 20 / 508 | 3 | fluorocarbon elastomer A |

| AB2FR8EHF | 0.2 | 20 / 508 | 8 | fluorocarbon elastomer A |

| AB3FR3EH1 | 0.2 | 30 / 762 | 3 | Teflon Encapsulated fluorocarbon elastomer |

| AB1FT3EH1 | 0.1 | 10 / 254 | 3 | Teflon Encapsulated fluorocarbon elastomer |

| AB1FT3EHF | 0.1 | 10 / 254 | 3 | fluorocarbon elastomer A |

| AB2FT3EH1 | 0.1 | 20 / 508 | 3 | Teflon Encapsulated fluorocarbon elastomer |

| AB3FT3EH1 | 0.1 | 30 / 762 | 3 | Teflon Encapsulated fluorocarbon elastomer |

| AB1FD8EH1 | 0.05 | 10 / 254 | 8 | Teflon Encapsulated fluorocarbon elastomer |

| AB2FD3EH1 | 0.05 | 20 / 508 | 3 | Teflon Encapsulated fluorocarbon elastomer |

| AB3FD3EH1 | 0.05 | 30 / 762 | 3 | Teflon Encapsulated fluorocarbon elastomer |

4 For prewet option add -K3 to end of part number.

5 Other O-ring materials are available.

Unit conversion:1 bar = 100 kilopascals

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.