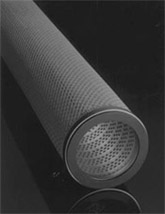

Pall PRE Cartridges Retrofit Peco Filters to Provide Improved Efficiency and Longer Filter Life

Pall PRE filters provide verifiable aerosol removal efficiency. They provide a replacement option to Peco FG336, FG372 and similar filters used in gas streams. Pall PRE filters are generally used to remove aerosols from industrial gas streams, and are installed for the following reasons:

Process Protection:

Aerosols cause foaming of glycol and amine systems, fouling of molecular sieves, irreversible damage to membrane separation units, plugging of heat exchangers, and catastrophic failure of catalysts. Removing contaminants from gas streams will minimize these problems.

Maintenance Efficiency:

Removal of aerosols will decrease compressor repairs, protect turbomachinery, prevent instrument malfunctions, increase accuracy of gas analysis and measurement, and increase gas processing efficiency.

Liquid Recovery:

Recovery of expensive glycol and amine solutions carried over with the exiting gas streams will result in immediate payback. A similar application is recovery of hydrocarbon condensate, directly from a producing well or downstream

of a separator.

Minimize Formation Damage:

Aerosols can plug formation during gas injection. The consequences can include: increased injection pressures, more frequent workover, and decreased operating efficiencies. Removal of contaminants from gas streams will prevent these problems.

PRE Filters Provide:

Consistent, High Quality Gas:

PRE cartridge filters offer verifiable aerosol removal ratings, ensuring retention of particles larger than the removal rating. Sock and wound cartridges do not offer the reliability and consistency of Pall filters.

Economical Operation:

The construction of PRE filters provides high void volume, more pores and long service life.

Reliability:

PRE filters have resin bonded cellulose fibers which inhibit media migration. Their rugged construction allows PRE filter cartridges to be handled as typical gas plant equipment. Sock and wound cartridges can shed fibers and unload previously removed particles.

Slug Recovery:

Liquid slugs are always a concern to operators. PRE fibers are slug-resistant — the filter rapidly returns to its pre-slug differential pressure. This ability to recover eliminates the necessity to change cartridges after each “upset” — the usual procedure for sock or wound filter elements.

| Cartridge Construction | ||

|---|---|---|

| Filter Medium: | Resin Bonded Cellulose | |

| Support Core: | Coated Carbon Steel | |

| Gaskets: | Buna N or Ethylene Polypropylene | |

| Cartridge Dimensions | ||

|---|---|---|

| Inner Diameter: | 3 1/3 inches | |

| Outer Diameter: | 4 1/4 inches | |

| Nominal Length: | 36 inches to replace Peco FG336 72 inches (2 x 36-inch units coupled) to replace Peco FG372 | |

| Filter Service Area: | 29 square feet | |

| Operating Characteristics | ||

|---|---|---|

| Maximum allowable differential pressure vs. temperature: | 60 psid at up to 275°F | |

Pall PRE Retrofit Series for Replacing Peco Filters

PRE series cartridges specifications:

P/N PRE003

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.