Single-Round Filter Housing

for Sanitary Liquid Filtration

FBT Series sanitary housings are designed specifically for liquid filtration in the food and beverage industry1.

- Enhanced cleanability and microbiological safety due to crevice-free, polished and hygienic design

- Corrosion resistance and durability with 316L stainless steel wetted parts and high-quality welds

- Cost-effective without sacrificing quality and performance

Features and Benefits

- Suitable for flow rates up to 91 liters/min (24 USgpm) depending on cartridge type and size

- Suitable for CIP and SIP

- Beveled housing tube sheet and aseptic-style housing seal provides enhanced drainability and a crevice-free connection between the housing head and bowl

- Electropolished head and elbows and mirror polished bowl ensures optimal cleanability in critical areas while maintaining cost-effectiveness

- New cartridge locking design features additional cut-outs to traditional half-moon portions of the Code 7 bayonet locks, enhancing cleanability and drainability

- Operator-friendly V-Clamp housing closure simplifies handling

- Design satisfies EC Pressure Equipment Directive (PED) 97/23/EC, ATEX 94/9/EC Group II Category 2

Minimum / Maximum Operating Pressure2

- -1 to 10 bar (-14.5 to 150 psig)

Minimum / Maximum Operating Temperature3,5

- Fluorocarbon Elastomer and Silicone seals -10 to 150 °C (14 to 300 °F) EPR seals -10 to 121 °C (14 to 250 °F)

Steam Sterilization3,5

- Fluorocarbon Elastomer and Silicone seals 3.7 bar / 150 °C max (53 psig / 300 °F) EPR seals 1 bar / 121 °C max (14.5 psig / 250 °F)

Materials of Construction

- Wetted parts 316L stainless steel

Housing Seal Options1, 4

- Fluorocarbon Elastomer

- Silicone

- EPR

Surface Finish

- < 0.8 micron Ra (< 32 Ra microinches)

Connections

- DIN 11851

- Clamp Coupling

- Butt Weld

Filter Cartridge Compatibility5

- Pall Code 2 or Code 7 single open-end

Design Specification

- Design capability of 4 times maximum operating pressure. Each housing is hydrostatically tested to 1.6 times maximum

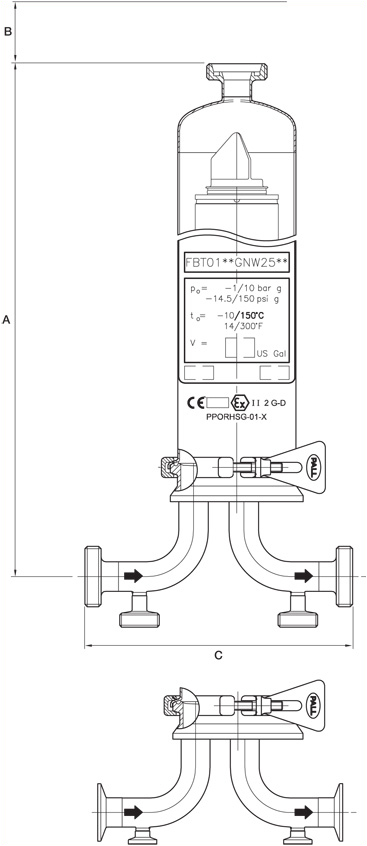

Nominal Dimensions in mm (inches)

| Code | Cartridge Height | A DIN Connec- tion |

A Clamp Connec- tion |

A Butt Weld Connec- tion |

B Element Removal | C DIN Connec- tion |

C Clamp Connec- tion |

C Butt Weld Connec- tion |

| 05 | 127 (5) | 316.5 (12.5) | 309.1 (12.2) | 302 (11.9) | 180 (7.1) | 230 (9.1) | 215 (8.5) | 173 (6.8) |

| 1 | 254 (10) | 441.5 (17.4) | 434.1 (17.1) | 427 (16.8) | 300 (11.8) | 230 (9.1) | 215 (8.5) | 173 (6.8) |

| 2 | 508 (20) | 701.5 (27.6) | 694.1 (27.3) | 687 (27.0) | 550 (21.7) | 230 (9.1) | 215 (8.5) | 173 (6.8) |

| 3 | 762 (30) | 961.5 (37.9) | 954.1 (37.6) | 947 (37.3) | 800 (31.5) | 230 (9.1) | 215 (8.5) | 173 (6.8) |

For specific dimensions, please contact Pall.

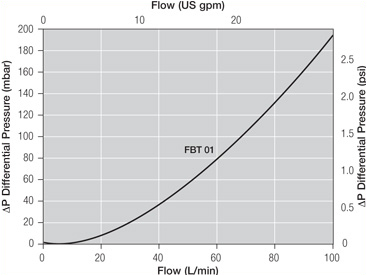

Typical Water Flow / Pressure Drop Characteristics6

Volume and Weight

| Code | Volume L (US gal) | Weight kg (lb) |

| 05 | 1.4 (0.37) | 3.4 (7.5) |

| 1 | 2.4 (0.63) | 3.9 (8.6) |

| 2 | 4.4 (1.16) | 5.0 (11.0) |

| 3 | 6.3 (1.66) | 6.0 (13.2) |

1Please contact Pall to ensure the products meet specific National Legislation and/or Regional Regulatory requirements for food contact use.

2Maximum operating pressure ratings are vessel ratings only. Safe operating temperature and pressure will depend on filter cartridge and seal used. For compatibility details, please contact Pall.

3For applications involving fluids below 0 °C (32 °F), please contact Pall.

4Check local pressure vessel code requirements.

5Refer to Pall Food and Beverage filter cartridge literature for additional guidelines on use.

Part Number: FBT < Cartridge Height Code from Table 1 > G < Inlet/Outlet Code from Table 2 >< Housing Seal Option from Table 3 > < Housing Design Code from Table 4 >

Table 1 - Cartridge Height

| Code | Cartridge Height |

| 05 | 127 mm (5 in.) |

| 1 | 254 mm (10 in.) |

| 2 | 508 mm (20 in.) |

| 3 | 762 mm (30 in.) |

Table 2 - Inlet/Outlet

| Code | Inlet / Outlet | Vent | Drain |

| NW25 | NW25 DIN 11851 | NW25 DIN 11851 | NW15 DIN 11851 |

| 23 | 1" Clamp Coupling | 1" Clamp Coupling | ½" Clamp Coupling |

| 02 | Butt Weld 25.4 x 1.6 | Butt Weld 12.7 x 1.6 | Butt Weld 12.7 x 1.6 |

Table 3 - Housing Seal

| Code | Housing Seal Options |

| H | Fluorocarbon Elastomer |

| H4 | Silicone |

| J | EPR |

Table 4 - Housing Design

| Code | Housing Design |

| Blank | Standard |

| 3A | 3-A Series |

Spare Parts

| Description | Standard Design / 3-A Design |

| Bowl Seal | GK1242PH01 (Fluorocarbon Elastomer) GK1242QL01 (Silicone) GK1242PX01 (EPR) |

| Bowl V-Clamp | ACS0942DA |

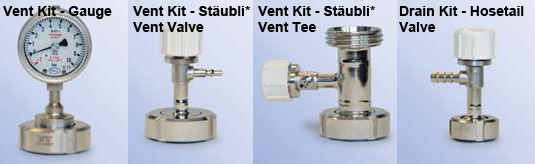

Optional Accessories

| Description | Connections+ | Seal Material | Part Number | Connections+ | Seal Material | Part Number |

| Vent Kit - Gauge | NW25 | H H4 J |

ACS0949AM ACS0950AU ACS0951AM |

1" Clamp Coupling | H H4 J |

ACS0958AM ACS0959AU ACS0960AM |

| Vent Kit -Stäubli* - Vent Valve | NW25 | H H4 J |

ACS0952AM ACS0953AU ACS0954AM |

1" Clamp Coupling | H H4 J |

ACS0961AM ACS0962AU ACS0963AM |

| Vent Kit - Stäubli* Vent Tee | NW25 | H H4 J |

ACS0946AM ACS0947AU ACS0948AM |

1" Clamp Coupling | H H4 J |

ACS0955AM ACS0956AU ACS0957AM |

| Drain Kit -Hosetail Valve (2 required per housing) | NW15 | H H4 J |

ACS0929EM ACS0930EU ACS0931EM |

1/2" Clamp Coupling | H H4 J |

ACS0932AM ACS0933AU ACS0934AM |

| Housing stand | FBT01STAND | |||||

+Connection kits are supplied either with DIN 11851 connection type or clamp coupling type. Please choose the desired option. Seal material options are H (Fluorocarbon Elastomer), H4 (Silicone) and J (EPR).

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.