Pall Advanta filter housings have been specifically designed and engineered for today’s manufacturing processes. These advanced housings are manufactured from 316L stainless steel and are engineered to meet the requirements of the BioPharmaceutical industry. State-of-the-art manufacturing technologies are used to construct a housing ideal for the most critical of applications. This multi-round version of the Pall Advanta housing range is designed to allow up to four filter elements in parallel arrangement. During the design process, critical features were optimized to ensure trouble-free use and low installation and maintenance costs. Areas included in this process were:

- Surface finish

- Suitability for CIP and SIP

- Integrity testing

- Incorporation into automated production processes

Features

- Aseptic design

- Crevice-free electropolished surface with an internal Ra value of < 0.4 µm (< 15 µin.)

- Fully self draining

- No dead legs

- Low hold-up volumes for maximum product recovery

- Quick fit Stäubli-type* connections for easy filter integrity testing

- Easy to use low-point sanitary drain valve

- Range of options to aid use in automated production systems

- Options available for use with CIP spray cleaning device

- Every housing supplied with a quality certificate and manufactured to ATEX Directive 94/9/EC (Group ll Category 2)

- Design variants to ASME and European Pressure Equipment Directive, CE marking available

*Stäubli is a trademark of Stäubli AG.

Materials of Construction

- Wetted Parts: AISI 316L stainless steel

- Clamp: AISI 316L and Nitronic1 60 Stainless Steel

- Seals: Silicone elastomer

- Surface Finish: All electropolished

Internal: Ra < 0.4 µm (< 15 µin.) (typical)

External: Ra < 0.8 µm (< 32 µin.) (typical)

Inspection Documentation

- Certificate type 2.3 to EN10204

Operating Conditions

- Maximum Operating Pressure: -1 to 10 barg (-14.52 to 150 psig)

- Maximum Operating Temperature:150 °C (300 °F)

Nominal Dimensions

| Part Number | Face to Face Width | Overall Height | Clearance Required |

| ALT41G31ABH4 | 319 mm (12.6 in.) | 528.5 mm (20.8 in.) | 310 mm (12.2 in.) |

| ALT41G31CBH4 | 319 mm (12.6 in.) | 486.5 mm (19.2 in.) | 310 mm (12.2 in.) |

| ALT41G31CDH4 | 319 mm (12.6 in.) | 486.5 mm (19.2 in.) | 310 mm (12.2 in.) |

| ALT41G31DDH4 | 319 mm (12.6 in.) | 476.5 mm (18.8 in.) | 310 mm (12.2 in.) |

| ALT41GNW50ABH4 | 319 mm (12.6 in.) | 528.5 mm (20.8 in.) | 310 mm (12.2 in.) |

| ALT41GA50ABH4 | 319 mm (12.6 in.) | 528.5 mm (20.8 in.) | 310 mm (12.2 in.) |

| ALT41G95ABH4 | 368 mm (14.5 in.) | 528.5 mm (20.8 in.) | 310 mm (12.2 in.) |

| ALT42G31ABH4 | 319 mm (12.6 in.) | 777.5 mm (30.6 in.) | 564 mm (22.2 in.) |

| ALT43G31ABH4 | 319 mm (12.6 in.) | 1025.4 mm (40.4 in.) | 818 mm (32.2 in.) |

| ALTA41G31ABH4 | 373 mm (14.7 in.) | 526 mm (20.7 in.) | 310 mm (12.2 in.) |

| ALTA41G31CBH4 | 373 mm (14.7 in.) | 526 mm (20.7 in.) | 310 mm (12.2 in.) |

| ALTA41G31CDH4 | 373 mm (14.7 in.) | 526 mm (20.7 in.) | 310 mm (12.2 in.) |

| ALTA41G31DDH4 | 373 mm (14.7 in.) | 487 mm (19.2 in.) | 310 mm (12.2 in.) |

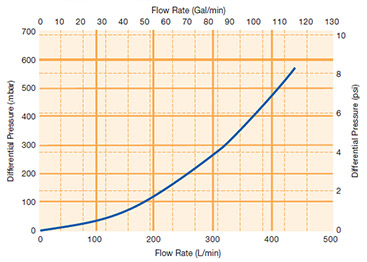

Typical Water Flow Rates3

1Nitronic is a registered trademark of Armco Inc.

2Full vacuum.

3The flow and pressure drop characteristics refer to the empty housing only for water at 20 °C (68 °F). For other liquids multiply pressure drop by relative density. To obtain the total pressure drop of a complete filter assembly, the cartridge pressure drop must be added. Please refer to the relevant filter cartridge literature or contact Pall.

Housings, Vessels, or Assemblies

This information is a guide to the part number structure and possible options. For availability of specific options and housing details, please contact Pall. Example Part Number: ALT A 4 2 G GA50 A D H4 (See bold references in tables below) Part Number: ALT < Design Code from Table 1 > 1 < Cartridge Code from Table 2 > G < Inlet/Outlet Code from Table 3 > < Vent Code from Table 4 > < Drain Code from Table 5 > H4

Table 1 - Design

| Code | Design |

| - | To European Pressure Equipment Directive |

| A | To ASME Code |

| D | To European Pressure Equipment Directive with enhanced documentation including 3.1b stamped material and certification |

Table 2 - Cartridge Type

| Code | Cartridge Type |

| 05 | AB05 code 2 |

| 1 | AB1 code 7 |

| 2 | AB2 code 7 |

| 3 | AB3 code 7 |

| 4 | AB4 code 7 |

Table 3 - Inlet/Outlet

| Code | Inlet and Outlet |

| 31 | 2 in. sanitary flange to ISO 2037/BS 4825 |

| GNW50 | Dairy fitting NW 50 to DIN 11851 |

| GA50 | Aseptic thread connection NW 50 to DIN 11864-1 |

| 95 | 60.3 x 2.3 mm4 wall butt weld to ISO 1127 |

| G34 | 50 mm (2 in.) NB SCH10 |

Table 4 - Vent

| Code | Vent |

| A | Sanitary valve fitting for Stäubli type couplings |

| C | For 1 1/2 in. sanitary flange connection to ISO 2852with side sanitary valve with quick release fitting for Stäubli type couplings |

| D | For 1⁄2 in. sanitary flange |

| E | Butt weld 13.5 x 1.6 mm3 |

| S | For 1 1/2 in. sanitary flange connection to ISO 2852 with side connection for 1⁄2 in. sanitary flange |

| N | No vent |

Table 5 - Drain

| Code | Drain |

| B | Sanitary valve with hosebarb for 8 mm ID tubing |

| D | For 1⁄2 in. sanitary flange connection |

| N | No drain |

Parts and Accessories

| Part Number | Description |

| ACS0598CM | Diaphragm valve for 1⁄2 in. sanitary flange compatible connections including clamp and silicone gasket |

| ACS0457FA | Pressure gauge kit -1 to 10 barg for 1 1⁄2 in. sanitary flange connection to ISO 2852 (includes clamp and gasket) |

| ORH4P-676 | Silicone housing closure gasket |

| ACS0602EM | Silicone housing valve gasket kit |

| LY00381 | Valve knob cap |

| CC41608CC00 | Valve stem |

| ACS0364DA | V-clamp housing closure |

| ACS0814AS | CIP Spray Device |

4Wall thickness as specified in ISO1127.

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.