Profile® UP Filter Cartridges

Pleated Depth Filters Designed for

High Particle Removal Efficiency

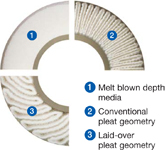

The filter cartridge combines the advantages of a continuously graded pore structure and unique laid-over pleat geometry to provide an increase in effective filtration area and service life. Fewer cartridges are required for a given flow rate than for a traditional depth style cartridge. Thus, filter vessels are correspondingly smaller, resulting in lower capital and installation costs, as well as reduced operating costs. | Features | Benefits |

| Fixed fiber matrix with no adhesives or surfactants |

|

| Media with laid-over pleat geometry |

|

| Polypropylene filter construction | Broad chemical compatibility |

Food Contact Compliance

- Food contact compliant filters are available. Please consult the Declarations of Compliance for applicable part numbers at the links below.

- Profile UP Filter Cartridge (AB Style “W” Code) Declaration of Compliance

- Profile UP Filter Cartridge (PUY Style “W” Code) Declaration of Compliance Materials of Construction

| Filter Medium | Pleated polypropylene |

| Support and Drainage | Polypropylene |

| Helical Wrap | Polypropylene non woven fabric |

| Cage, Core, Fin End and End Cap | Polypropylene |

| AB Style Cartridges Only | |

| Adaptor | Polypropylene with a stainless steel reinforcing ring |

| O-ring Seal | Ethylene Propylene Rubber or Silicone Elastomer |

| PUY Style Cartridges Only | |

| Gasket | Ethylene Propylene Rubber |

Operating Characteristics in Compatible Fluids1

| Maximum Differential Pressure | Operating Temperature |

| 4.1 bard (60 psid) (forward) | <30 °C (86 °F) |

| 3.4 bard (50 psid) (forward) | <50 °C (122 °F) |

| 2 bard (29 psid) (forward) | <70 °C (158 °F) |

| 1 bard (14.5 psid) (forward) | <80 °C (176 °F) |

| 1 bard (14.5 psid) (reverse) | <20 °C (68 °F) |

1 Fluids which do not swell, soften, or adversely affect any of the filter components

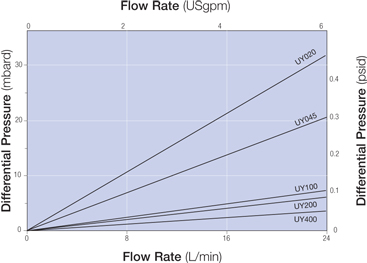

Typical Flow Rates2

2Typical initial clean delta p per 254 mm (10 inch) cartridge, water at 20 °C (68 °F).

For liquids with viscosity greater than 1 cP, multiply the delta p by the viscosity.

Liquid Removal Rating

| Grade | Rating (μm) at 99.98% Efficiency (ß-5000) | Rating (μm) at 90% Efficiency (ß-10) |

| UY020 | 2.03 | <1.0 |

| UY045 | 4.5 | 1.2 |

| UY100 | 10 | 4.3 |

| UY200 | 20 | 11 |

| UY400 | 40 | 18 |

Profile UP filter cartridge liquid retention ratings are based on modified OSU-F2 test.

Sterilization and Sanitization3

| Method | Temperature |

| In-situ Steam Sterilization | 125 °C (257 °F) |

| In-situ Hot Water Sanitization | 80 °C (176 °F) |

3For applications requiring in situ sterilization or sanitization Pall recommends the use of Code 7 adaptors to ensure filter sealing after cooling. Cartridges should be cooled to system operating temperature prior to use.

Quality

- Cartridges produced in a controlled environment

- Manufactured according to ISO 9001:2008 certifiedQuality Management System

Example Part Numbers:AB2UY0457WH4

(See bold references in tables below.)

Table 1 - Nominal Length

| Code Description | Description |

| 1 | 254 mm (10 in.) |

| 2 | 508 mm (20 in.) |

| 3 | 762 mm (30 in.) |

| 4 | 1016 mm (40 in.) |

Table 2 - Removal Rating4

| Grade | Rating (μm) at 99.98% Efficiency (ß-5000)5 | Rating (μm) at 90% Efficiency (ß-10) |

| UY020 | 2.0 | <0.1 |

| UY045 | 4.5 | 1.2 |

| UY100 | 10 | 4.3 |

| UY200 | 20 | 11 |

| UY400 | 40 | 18 |

4 Profile UP filter cartridge liquid retention ratings are based on a modified OSU-F2

single pass test.

5 The UY020 grade has a 99% removal efficiency (ß-100).

Table 3 - Adaptor

| Code | Description |

| 3 | SOE - single open end with flat closed end and external 222 O-rings |

| 7 | SOE - single open end with fin end; 2 locking tabs and external 226 O-rings |

| 8 | SOE - single open end with fin end and external 222 O-rings |

(Code 3, 7 and 8 may be available in selected grades, confirm code availability with your Pall representative.)

Table 4 - O-ring Seal Material

| Code | Description |

| H4 | Silicone Elastomer |

| J | Ethylene Propylene Rubber |

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.