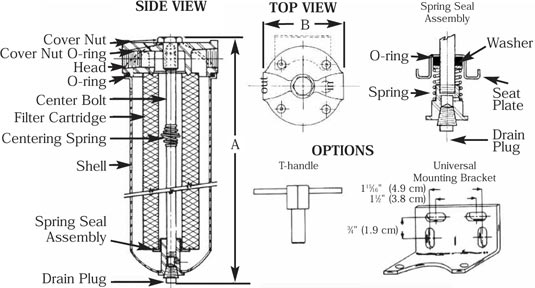

LMO Spring Seal Series Filter Housings

Self-Adjusting Sealing Device Ensures

Positive Filter Cartridge Seal

- Provides positive sealing of non-compressible filters1 such as pleated, carbon, metallic, and membrane cartridges

- Accepts 10.2 cm (4 in), 25.4 cm (10 in), 50.8 cm (20 in), or 76.2 cm (30 in) DOE filter cartridges2

- O-ring head and shell seal minimizes fluid leakage

- In-line inlet and outlet connections for easy installation

- Cast iron and carbon steel, brass and 316 stainless steel, or all 316 stainless steel materials of construction

1The LMO Spring Seal Series housing is not recommended for metallic cartridges. For metallic cartridges use the LMO Vari-Seal housing only.

2When fitting with 4 in (10.2 cm) DOE membrane filters, please order filters under Code 550 to assure proper fit.

Materials of Construction

| Construction | Head3 | Shell |

| LMOSS | Cast Iron4 | 316 Stainless Steel |

| LMOSS S | Cast 316 Stainless Steel | 316 Stainless Steel |

Maximum Operating Pressure

- 7.2 bar (105 psig) @ 93 °C (200 °F)

Connections

- Inlet/Outlet: 1/2", 3/4", or 1" NP

- Drain

- LMOSS: Drain Plug, 316 Stainless Steel, 1/4" NPT

- LMOSS S: Drain Plug, 316 Stainless Steel, 1/4" NPT

Shell O-rings

- Ethylene Propylene (standard), Nitrile, FEP, Fluorocarbon Elastomer, Neoprene, Silicone Elastomer

Cover Nut O-ring

- FEP (standard)

Bracket Option

- Stainless steel brackets are available as a standard option

T-Handle Option

- T-handle cover nuts are available in carbon steel or 316 stainless steel. Standard units are supplied with hex head cover nut.

Flange Option

- 150 lb. ANSI raised face flanges are available on the 316 stainless steel units only

Dimensional Data (Nominal)

| Connection Size | Dimensions cm (in) | |||||||

| Model | 1/2 in. | 3/4 in. | 1 in. | Flow Rate5 gpm | A | B | Sealing Distance cm (in) | Weight kg (lbs) |

| LMOSS10 | X | X | to 37.9 (10) | 34.3 (13.5) | 12.1(4.75) | 24.8 - 25.6 (9.75 - 10.06) | 3.1 (6.75) | |

| LMOSS20 | X | X | to 75.7 (20) | 59.7 (23.5) | 12.1(4.75) | 50.2 - 51.1 (19.75 - 20.13) | 4.1 (9) | |

| LMOSS10S | X | X | X | to 37.9 (10) | 34.3 (13.5) | 12.1(4.75) | 24.8 - 25.6 (9.75 - 10.06) | 3.1 (6.75) |

| LMOSS20S | X | X | to 75.7 (20) | 59.7 (23.5) | 12.1(4.75) | 74.9 - 76.7 (19.5 - 20.125) | 4.1 (9) | |

| LMOSS30S | X | X | to 113.6 (30) | 85.1 (33.5) | 12.1(4.75) | 49.5 - 51.1 (29.5 - 30.19) | 5.1 (11.25) | |

3Housing head has mounting bosses which accept self-tapping screws.

4Painted exterior .

5Dependent upon cartridge selection, fluid viscosity and allowable pressure drop at various flow rates. Refer to cartridge nomograph to determine initial pressure drop of filter cartridge.

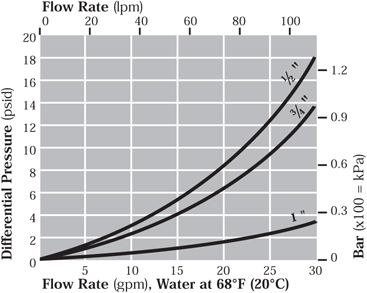

Housing Differential Pressure vs. Liquid Flow Rate

Unit Conversion: 1bar = 100 kPa

For liquids other than water, multiply differential pressure by specific gravity

Housings, Vessels, or Assemblies

Example Part Number: LMOSS 10 S - 3/4 (See bold references in tables below)

Part Number: LMOSS < Length Code from Table 1 > < Material Code from Table 2 > - < Connection Size Code from Table 3 > < Connection Style Code from Table 4 >

Table 1 - Cartridge Length

| Code | Cartridge Length (cm/in) |

| 4 | 10.2/4 |

| 10 | 25.4/10 |

| 20 | 50.8/20 |

| 30 | 76.2/30 |

Table 2 - Materials of Construction

| Code | Materials of Construction |

| Blank | Cast Iron and 316 Stainless Steel |

| S | 316 Stainless Steel |

Table 3 - Connection Sizes

| Code | Connection Size |

| 1/2 | 1/2 in. |

| 3/4 | 3/4 in. |

| 1 | 1 in. |

Table 4 - Connection Styles

| Code | Connection Style |

| Blank | NPT |

| F | Flange6 |

6Flanges on the LMOSS S are welded to the cast head. Flanges are not available on the LMOSS B or LMOSS models.

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.