- Accepts Seven 10 in. (25.4 cm), 20 in. (50.8 cm), 30 in. (76.2 cm), or 40 in. (102 cm) Cartridges

- Electropolished 316L Stainless Steel Materials of Construction for Maximum Corrosion Resistance

- Liquid Flow Rates to 100 GPM (379 LPM), max.

- Operating Pressures to 150 PSIG (10.3 BAR) @ 200 °F (93 °C)

- Optional ANSI Raised Face 2 in. Flange Connections

- Universal Seat Cup Accepts DOE or #222 SOE Cartridges

- V-Band Clamp Closure Permits Quick, Easy Cartridge Change Outs

- Final DI Water Rinse

- Available with 2 in. Tri-Clover1 Sanitary Flange

1Registered trademark of Tri-Clover, Inc.

Materials of Construction

- Head & Shell: 316L Stainless Steel

- Vent Plug: 316L Stainless Steel

- Drain Cap: 316L Stainless Steel

- Seat Cups: 316L Stainless Steel

Maximum Operating Pressure

- 150 psig (10.3 bar) @ 200 °F (93 °C)

Connections

- lnlet/Outlet: 2" Male NPT or Tri-Clover Fitting (pipe size

- Drain: 3/4" Male NPT

- Drain/Vent: 1/4" NPT Coupling

Shell O-Rings

- Ethylene Propylene (standard), Fluorocarbon Elastomer, Silicone Elastomer

Flange Option

- 150 lb. ANSI raised flanges available

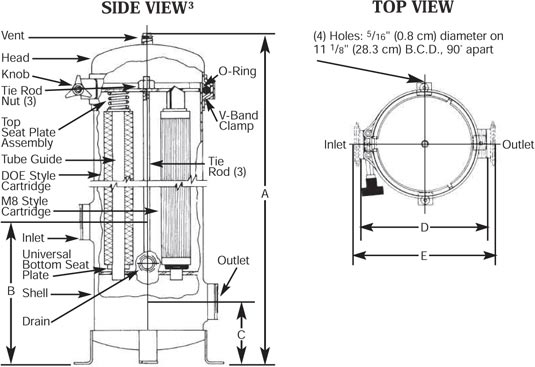

Dimensional Data (Nominal)

| Dimensions - inches (cm) | |||||||||

Model | Liquid2 Flow Rates - gpm (lpm) | A | B | C | D | E | Maximum Cartridge Diameter - in. (cm) | Weight - pounds (kg) | Minimum Clearance - in. (cm) |

| 7MEGA +1-2 | to 60 (227) | 25 (63.5) | 11 1⁄2 (29.2) | 5 1⁄2 (14) | 12 (30.3) | 12 7⁄8 ±1⁄4 (32.7±0.64) | 2 3⁄4 (7) | 41 (18.6) | 31 (78.7) |

| 14MEGA +2-2 | To 100 (379) | 33 1⁄2 (85.1) | 11 1⁄2 (29.2) | 5 1⁄2 (14) | 12 (30.3) | 12 7⁄8 ±1⁄4 (32.7±0.64) | 2 3⁄4 (7) | 46 (20.9) | 48 1⁄2 (123.2) |

| 21MEGA +3-2 | To 100 (379) | 44 (112) | 11 1⁄2 (29.2) | 5 1⁄2 (14) | 12 (30.3) | 12 7⁄8 ±1⁄4 (32.7±0.64) | 2 3⁄4 (7) | 52 (23.6) | 72 (183) |

| 28MEGA +4-2 | To 100 (379) | 54 1⁄2 (138.4) | 11 1⁄2 (29.2) | 5 1⁄2 (14) | 12 (30.3) | 12 7⁄8 ±1⁄4 (32.7±0.64) | 2 3⁄4 (7) | 58 (26.3) | 89 1⁄2 (227) |

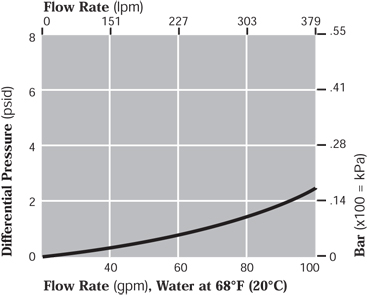

Housing Differential Pressure vs. Liquid Flow Rate

For liquids other than water, multiply differential pressure by specific gravity.

1Registered trademark of Tri-Clover, Inc.

2Registered trademark of DuPont Dow Elastomers.

3Dependent upon cartridge selection, fluid viscosity, and allowable pressure drop. See graph below for housing pressure drop at various flow rates. Refer to cartridge nomograph to determine initial pressure drop due to the filter cartridge. The 28MEGA+ may be used to provide longer cartridge life and lower initial pressure drop. A flow rate in excess of 100 gpm (379 lpm) is not recommended with 2" connections. Consult factory for higher flow rates.

4 Side view shows sealing arrangement for DOE5 style cartridges on left (MEGA+-IP) and M3 (Code 3) or M8 (Code 8) style cartridges (M8 shown) on right (MEGA+ model).

Housings, Vessels, or Assemblies

This information is a guide to the part number structure and possible options. For availability of specific options and housing details, please contact Pall. Example Part Number: 7 MEGA+ 2 -2 F (See bold references in tables below) Part Number: < Equivlaent Code from Table 1 > MEGA+ < Equivalent Code from Table 2 > - 2 < Connection Code from Table 3 >

Table 1 - No. of 10 in. Equivalnets

| Code | No. of 10 in. Equivalents |

| 7 | 7 |

| 14 | 14 |

| 21 | 21 |

| 28 | 28 |

Table 2 - No. of 10 in. Equivalnets per Column

| Code | No. of 10 in. Equivalents Per Column |

| 1 | 1 |

| 2 | 2 |

| 3 | 3 |

| 4 | 4 |

Table 3 - Connection Styles

| Code | Connection Styles |

| Blank | NPT |

| F | Flange |

5When using double open end style filter cartridges, tube guides and springs are required. Contact your Pall Distributor for part numbers.

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.