CFS NEO Systems for Cold Filtration of Beer

Pall’s CFS NEO is a membrane filter system for the final filtration of beer directly upstream the filling line. Using CFS NEO eliminates the requirement for thermal treatment by utilizing membrane cartridges and therefore, maintains the original taste and freshness of the beer with a high microbial safety. The CFS NEO design incorporates learnings from the successful installation of more than 250 CFS classic system installations worldwide, providing optimal taste at maximum microbial safety.

Description

The CFS NEO is a fully automated standalone membrane filter system. The filter cartridges are installed within individual cluster housings, each holding seven cartridges. The housings are arranged in parallel on a modular skid and controlled by individual outlet valves.

In addition to the cluster housing module, the system includes modules for clean-in-place (CIP) manifold connection valves manifold with all the inlet and the controls, including the integrity test device.

Installation is directly upstream of the filling line without the requirement for a buffer tank. Operation is independent of other brewery systems with interfaces to the filler and BBT controls.

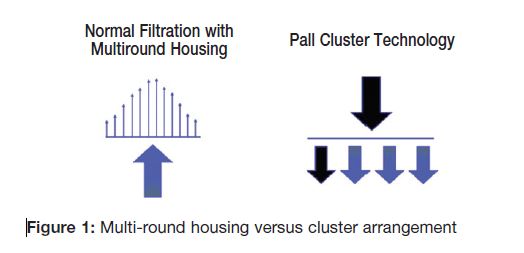

Cluster Technology

With cluster technology, the number of cartridges used for filtration

Technical Data

| CFS NEO | |

| Flow rate range (hl/h; |

50 – 600 |

| Flux/housing (hl/h; lbs/h) | 15 – 30 |

| Max pressure (bar/psi) | 6.0 / 87 |

| Max temperature (°C/F) | 85 / 185 |

| Integrity test | Forward |

| Number housings/unit | 4 – 20 |

| Housing volume net (l/gal) | 8.3 / 2.2 |

| Housing weight net (kg/lbs) | 43 / 94 |

| Number Cartridges/housing | 7 |

| Cartridge adapter | Code 28 |

| Specific system volume (l/m²) | 2.6 – 2.8 |

| CE Mark | Yes |

| Connection to line | Double seat valve |

Pasteurizer Replacement Filter Cartridges

For use in combination with the new CFS NEO system, Pall has specifically developed the Pasteurizer Replacement (PARE) family of filter cartridges, consisting of pre-filters and hydrophilic membrane filters for beer application.

The sterile filter cartridges are suitable for exposure to repeated hot water sanitization and in situ steam sterilization cycles for longer service life.

They are also qualified to remove beer specific microorganisms. Optimized support and drainage materials provide increased mechanical strength during operation, repeated hot water, chemical

For more details, see Product Data Sheet FBDSPAREEN.

Membrane Cleaning

The special cleaning and regeneration process ensures high membrane performance combined with long membrane service life:

- Cold and warm water flush at max 64 °C / 149 °F

- Chemical clean a concentration of to 1% caustic at 64°, alternative conditioned caustic cleaner

- Regeneration with

Ultimase FMC at 45-50 °C / 113-122 °F and pH 4.5 - Sanitization at 82-85 °C / 180-185 °F for 30 min

- Integrity test after each cleaning/regeneration

- Pressurize with CO2

Materials and Regulations

CFS NEO Filter systems are manufactured according to ISO 9001:2015 certified Quality Management System and CE marked. Materials in use fulfil Food Contact Compliance and FDA regulations. Declaration of compliance to specific National Legislation and/or Regional Regulatory Requirements for food contact use are available on the Pall website.

For specific

The CFS NEO is designed for the “sterile” filtration of beer upstream of the filling machine (keg/can/bottle/container). System ae available to accommodate throughputs between 50 and 600 hl/h. The design is available for batch (CFS NEO) and continuous operation (CFS NEO Conti).

The membrane filter module can also be expanded with a pre-filtration unit (CFS NEO Plus) for superior pre-clarification to extend the membrane cartridge lifetime.

Quality

CFS NEO, combined with PARE cartridges, gives maximum microbial safety, controlled and documented with integrity testing. The system and process

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.