The Smart Choice for Wine Clarification

The Oenoflow XL-S systems are specifically designed to meet the needs and requirements of mid size wineries. Clarification is achieved in a single process step without the need for filter aids, centrifugation or significant impact on the organoleptic characteristics of the wine. By increasing yields, reducing waste volumes and maintaining more consistent filtrate quality, the fully automated systems provide a cost saving sustainable alternative to traditional wine clarification methods. The systems utilize Pall’s proven hollow fiber membranes with unique mechanical strength and excellent chemical resistance which allow high productivity and repeated exposure to aggressive cleaning regimes. The large surface area modules enable manufacture of compact systems with low water and chemical consumption in line with winery conservation programs. With adjustable operating cycles, Pall’s proprietary Low Concentration Volume (LCV) option, and automatic chemical dosing, the Oenoflow XL-S system is the smart solution for reliable and economical wine clarification. Additionally the small batch program provides the flexibility required by most modern wine cellars, packagers and mobile bottlers.Benefits

The Oenoflow XL-S systems incorporate unique features which enable wineries to perform clarification at low operating costs while maintaining wine quality. These include:- PVDF membranes with high mechanical strength for longer service life

- High area, high flow modules for more compact and more economical systems

- Back pulse capability for increased system productivity

- Transparent module housings to confirm filtrate quality and enhance troubleshooting capabilities

- Fully automated working cycles for unattended operation and reduced labor and downtime

- On board concentration and filtrate tanks for operation independent of winery conditions

- Proprietary LCV option for high wine yield

- Small batch program isolating 1 module for efficient processing of batches up to 1000 L

- Water “solo” back flushes for highly effective solids removal

- Automated chemical dosing for safe and easy cleaning

Compliance

- The Oenoflow XL-S systems are CE to demonstrate compliance with relevant regulations including the European Pressure Directives.

- Various Oenoflow modules have been qualified for compliance to specific regulatory standards for products coming into contact with foodstuffs. Please contact Pall for details.

- Oenoflow Crossflow Microfiltration System Declaration of Compliance

Operating Conditions

- Inlet pressure: 0.5 bar to 3.5 bar (7 psi to 50 psi)

- Temperature: -4 °C to 25 °C (24 °F to 77 °F)

- Maximum temperature for cleaning: 65 °C (150 °F)

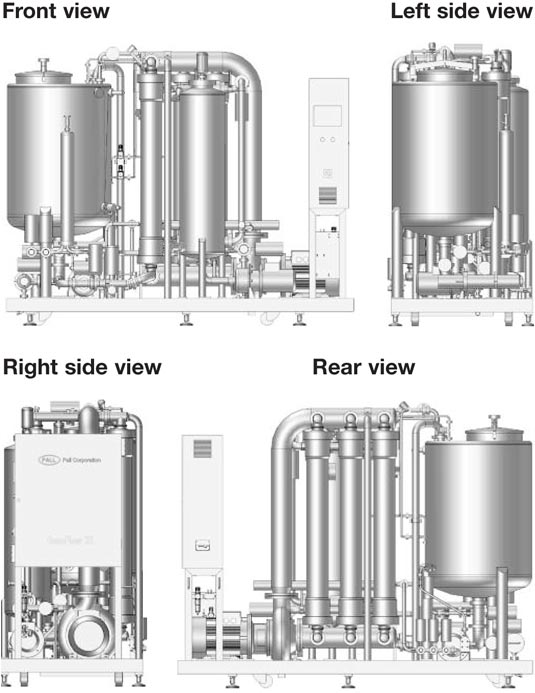

Oenoflow XL-S System Components

The Oenoflow XL-S systems are fully automated, modular systems available with 3 up to 6 crossflow filtration modules. All metal wetted parts are 304 Stainless steel. The piping manifold, membranes, pumps and instruments are mounted on a mobile frame which includes the following:- Stainless steel pre-filter screen for large particles

- On board concentration/cleaning tank

- Feed pump

- Circulation pump

- Filtrate reservoir

- Filtrate/back flush pump

- Magnetic flow meter with batch control

- CIP system with 1 micron, 30 inch water filter and temperature control

- Automatic chemical dosing with 3 supply inlets

- Touch screen PLC

- Pressure, temperature and dry run protection

- A power jack for an external transfer pump

Oenoflow XL-S Membranes

The Oenoflow XL-S modules incorporate Pall’s proven symmetric hollow fiber membranes. The large diameter, high flow modules with 21.5 square meters of filter area, have at least twice the filter area of typical competitive hollow fiber modules.The module components include:

- Membrane: PVDF

- Potting: Epoxy resin

- Sleeve: Polypropylene

- Housing: Transparent polysulfone

- Seals: Ethylene Propylene copolymer

Systems

Standard Filtration Skid Specifications

| Model | No. of Modules | Filter Area (m2) | Average Flow Rate2 | Length | Width | Height | Weight (empty) |

| Oenoflow XL-3S | 3 | 64.5 | 30 - 45 hl/h (790 – 1190 gph) | 2.60 m (8.53 ft) | 1.20 m (3.94 ft) | 2.15 m (7.05 ft) | 1420 kg (3130 lbs) |

| Oenoflow XL-4S | 4 | 86 | 40 - 60 hl/h (1050 – 1580 gph) | 2.70 m (8.86 ft) | 1.20 m (3.94 ft) | 2.15 m (7.05 ft) | 1550 kg (3417 lbs) |

| Oenoflow XL-5S | 5 | 107.5 | 50 - 75 hl/h (1320 – 1980 gph) | 3.00 m (9.84 ft) | 1.20 m (3.94 ft) | 2.15 m (7.05 ft) | 1590 kg (3505 lbs) |

| Oenoflow XL-6S | 6 | 129 | 60 - 90 hl/h (1580 – 2380 gap) | 3.00 m (9.84 ft) | 1.20 m (3.94 ft) | 2.15 m (7.05 ft) | 1690 kg (3725 lbs) |

Oenoflow XL-S Standard Options

The following options are available for additional supply:- LCV with small batch program

- Nitrogen purge and blanketing

- Spray ball kit for T11

- External bleed

- Manual dual pre-filter screens1

- External transfer pump1

- Tele-service adaptor

- Stainless steel dummy modules for future expansion capacity

- High Pressure (HP) option for treatment of sparkling wine under isobaric conditions

1These options are supplied as external equipment options mounted on their own mobile frame.

2The flow rates for the various Oenoflow XL models are averages for the complete filtration cycle, and dependent on the wine characterisitics and pre-treatment

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.