Documents

Datasheets

Download:Description

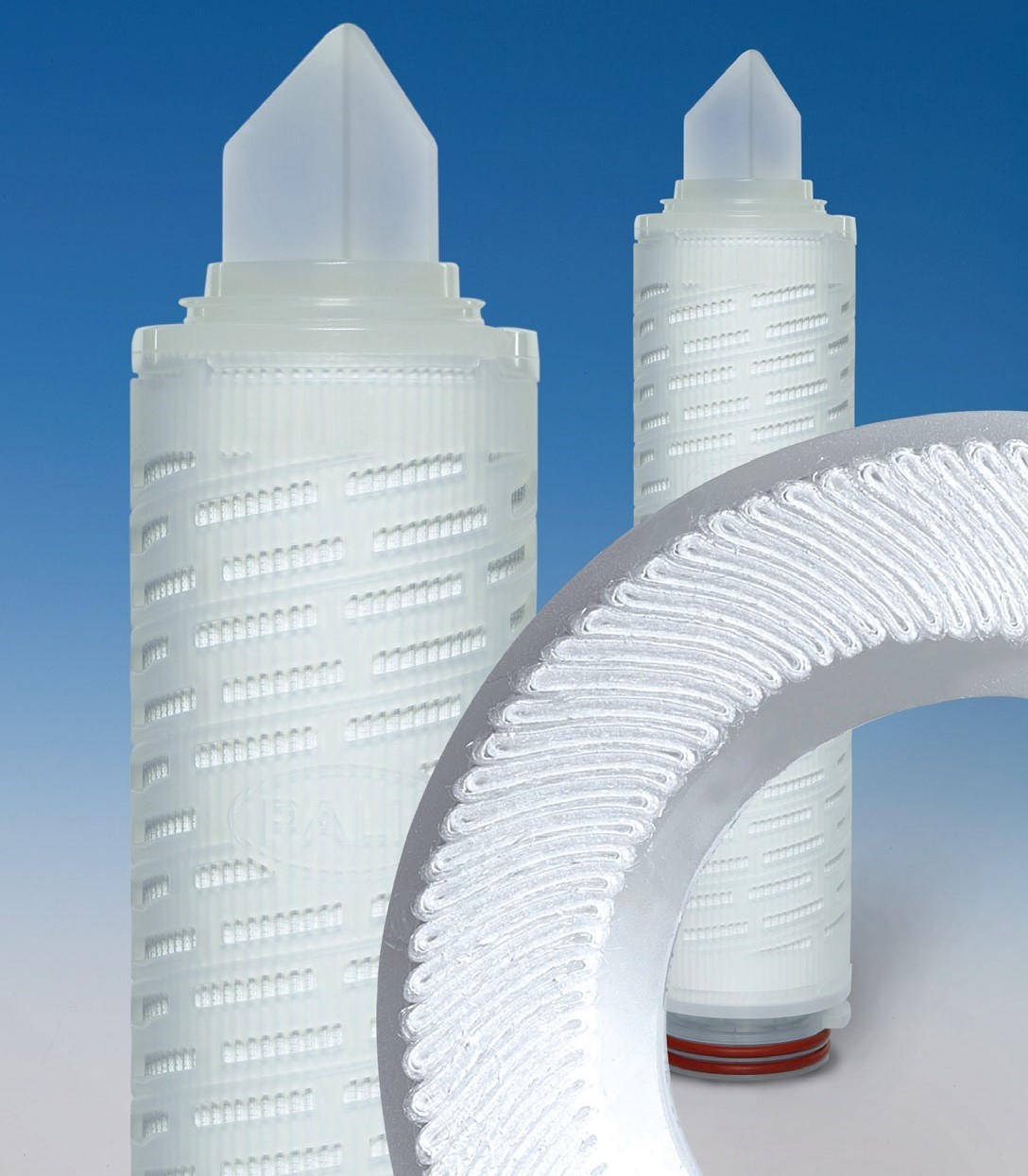

Supor® Beverage Filter Cartridges

For Final Filtration

Supor Beverage filter cartridges are 0.65 µm hydrophilic membrane filters designed for reliable retention of spoilage microorganisms in the final filtration of a range of beverages including wine and water.

Description

The Supor Beverage filters were developed and validated for removal of common spoilage microorganisms.

The cartridges are constructed from one layer of polyethersulfone (PES) membrane in a laid-over pleat configuration. The single open ended (SOE) configuration is designed to fit into sanitary housings to ensure effective microbial reduction and assembly integrity.

Supor Beverage filter cartridges are suitable for exposure to repeated hot water sanitization and in situ steam sterilization cycles for longer service life. The laid-over pleat configuration combined with optimized support and drainage materials, provide increased mechanical strength during operation, repeated hot water, chemical and steam sanitization and thus, high throughput.

| Features | Benefits |

| Inert polyethersulfone (PES) media |

|

| Cartridges resistant to numerous sanitization cycles |

|

| Hydrophilic membrane |

|

| Validated with wine spoilage microorganisms |

|

| Individually serialized cartridges |

|

| Integrity testable |

|

| Multiple adaptor options |

|

Quality

- Cartridges produced in a controlled environment

- Manufactured according to ISO 9001:2015 certified Quality Management System

Food Contact Compliance

Please refer to the Pall website http://www.pall.com/foodandbev for a Declaration of Compliance to specific National Legislation and/or Regional Regulatory requirements for food contact use.Specifications

Microbial Removal Rating

| Test Organism | Log Reduction Value (LRV) for BK Grade |

| Escherichia coli (ATCC 25922) | >10 |

| Saccharomyces cerevisiae | Yeast free* |

| Dekkera bruxellensis (ATCC 64276) | Yeast free* |

*Filters provided a yeast free effluent when challenged.

Materials of Construction

| Filter medium* | Polyethersulfone (hydrophilic) |

| Support and drainage | Polypropylene |

| Core, Cage, End Cap and Fin End | Polypropylene |

| Adaptor | Polypropylene with stainless steel reinforcing ring |

| O-ring Seal | Ethylene propylene rubber or Silicone elastomer |

*Each 10" module contains 0.75 m2 (8.0 ft2) of effective filtration area for BK grade.

Technical Information

Operating Characteristics in Compatible Fluids1

| Maximum Differential Pressure | Operating Temperature | |

| 5.5 bard (79.8 psid) (forward pressure) | 25 °C (77 °F) | |

| 4.0 bard (58.0 psid) (forward pressure) | 80 °C (176 °F) | |

| 1.0 bard (14.5 psid) (reverse pressure) | 40 °C (104 °F) | |

| 300 mbard (4.4 psid) (forward pressure) | during in-situ steam sterilization | |

1Compatible fluids are defined as those which do not swell, soften or attach any of the filter components

Sterilization and Sanitization

| Media | Temperature | Cumulative Exposure Time/cycles2 | |

| BK Grade | |||

| Steam | 125 °C (257 °F) |

125 x 20 min cycles |

|

| Hot Water | 90 °C (194 °F) |

200 x 30 min cycles |

|

| Peracetic acid (PAA), 325 ppm PAA (1275 ppm H2O2to give 1600 ppm of total peroxides) |

ambient | 2000 hours | |

| Potassium metabisulphite (1000 ppm) |

ambient | 1000 hours | |

2Measured under laboratory test conditions. The actual cumulative time depends on the process conditions. For applications requiring sterilization or sanitization Pall recommends the use of Code 7 adaptors to ensure filter sealing after cooling. Cartridges should be cooled to system operating temperature prior to use. Contact Pall for recommended procedures

Chemical Cleaning (static soak conditions)

| Media | Temperature | Cumulative Exposure3 |

| BK Grade | ||

| Caustic 2% | 50 °C (122 °F) | 400 hours |

| Caustic 2% | 80 °C (176 °F) | 200 hours |

3 Measured under laboratory test conditions. The actual cumulative time depends on the process conditions.

Pressure Drop vs. Liquid Flow Rate

| Code | Value |

| BK | 42.5 liters per minute @ 100 mbar (7.6 US gpm @ 1 psi) |

4Typical initial clean media differential pressure (dP) per 254 mm (10”) cartridge for water at 20 °C (68 °F); viscosity 1 centipoise. For 508, 762 mm and 1016 mm configurations divide the differential pressure by 2, 3, and 4 respectively.

Type

Ordering Information

Ordering Information

Cartridge Part Number

AB [Table 1] SBK [Table 2] W [Table 3]This is a guide to the Part Numbering structure only. For specific options, please contact Pall.

Table 1: Nominal Length

| Code | Description |

| 1 | 254 mm (10”) |

| 2 | 508 mm (20”) |

| 3 | 762 mm (30”) |

| 4 | 1016 mm (40”) |

Table 2: Adaptor

| Code | Description |

| 3 | SOE – single open end with flat closed end and external 222 O-rings |

| 7 | SOE – single open end with fin end, 2 locking tabs and external 226 O-rings |

| 8 | SOE – single open end with fin end and external 222 O-rings |

| 28 | SOE – single open end with fin end, 3 locking tabs and external 222 O-rings |

Table 3: O-Ring Seal Material

| Code | Description |

| H4 | Silicone Elastomer |

| J | Ethylene Propylene Rubber |

Reviews

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.