Profile Coreless filters are large diameter cartridges designed for cost-effective, highly efficient clarification and particle filtration in high flow rate food and beverage applications.

Description

Profile Coreless filter elements combine Pall proven Profile depth filter technology with a design that eliminates the core to provide a convenient, cost effective and environmentally-friendly solution for liquid clarification applications.

Constructed of melt blown polypropylene media, Profile Coreless elements feature a fixed fiber matrix with graded pore structure. With coarsest pore sizes in the outermost layers and decreasing pore sizes towards the innermost layers of the cartridge, pre-filtration and fine filtration can occur within the same cartridge. These features are the key to the superior removal performance and high contaminant holding capacity of these filters.

The large diameter filter elements enable smaller sizing for a given flow rate than standard melt blown cartridges. Filter vessels are correspondingly smaller, resulting in lower capital and installation costs, as well as reduced operating costs.

The Profile Coreless filter element fits over a 316L stainless steel core, which is retained inside the filter housing. At change-out, the element is simply pulled up over the core, which is then ready to accept the replacement element.

Features and Benefits

| Features | Benefits |

| Large diameter cartridge utilizing high void volume, low differential pressure media |

|

| Continuous graded pore structure with pre-filter section and high performance inner section |

|

| Highly stable all-polypropylene structure with fixed fiber matrix and no adhesives or surfactants |

|

| Separate stainless steel core retained in filter housing |

|

Materials of Construction

| Filter Medium: | Polypropylene |

Food Contact Compliance

Please refer to the Pall website for a Declaration of Compliance to specific national legislation and/or regional regulatory requirements for food contact use.

Technical Information

The technical information provided is based on controlled laboratory tests done on typical production filters at the conditions described, unless otherwise indicated. Actual operating conditions may affect the filter's performance.

Operating Characteristics in Compatible Fluids1

| Maximum Differential Pressure2 | Operating Temperature |

| 4.0 bard (58 psid) | 32 °C (90 °F) |

| 1.0 bard (14.5 psid) | 82 °C (180 °F) |

1 Fluids which do not swell, soften or adversely affect any of the filter components

2 In forward (out to in) flow direction.

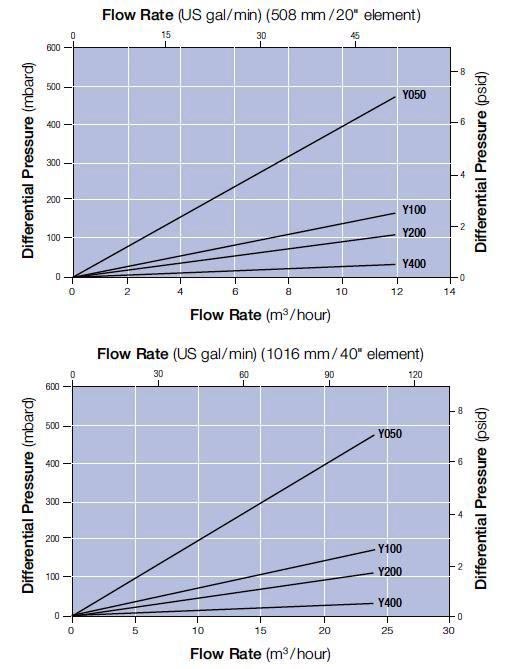

Typical Flow Rates3

3 Typical initial clean delta p, for 508 mm (20”) and 1016 mm (40") elements, water at 20 °C (68 °F). For assistance in filter assembly sizing, especially for fluids with a viscosity greater than 1 centipoise, contact your Pall representative.

Profile Coreless filters (1016 mm / 40”) are generally recommended for water flow rates up to 20 m3 / hour (88 US gal / min). Please contact your Pall representative for individual fluid applications and product options more suitable to higher flow rates.

Quality

- Cartridges produced in a controlled environment

-

Manufactured according to ISO 9001:2008 certified Quality Manufacturing System

- Operating and Installation Procedures - Pall® Coreless Filter Element

FP01109

FP01109 - Operating and Installation Procedures - Pall® Coreless Filter Assembly

LP00648

LP00648

Element Part Number: E60 [Table 1] [Table 2] W

Example Part Number: E604Y400W

See bold reference code in tables.

Table 1 : Nominal Length

| Code | Description |

| 2 | 508 mm (20") |

| 4 | 1016 mm (40") |

Table 2: Removal Rating4

| Code | Rating (μm) at 99.98% efficiency (B-5000) |

| Y050 | 6 |

| Y100 | 10 |

| Y200 | 20 |

| Y400 | 40 |

4 Profile Coreless filter cartridge liquid retention ratings are based on a modified OSU-F2 single pass test in an aqueous medium.

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.