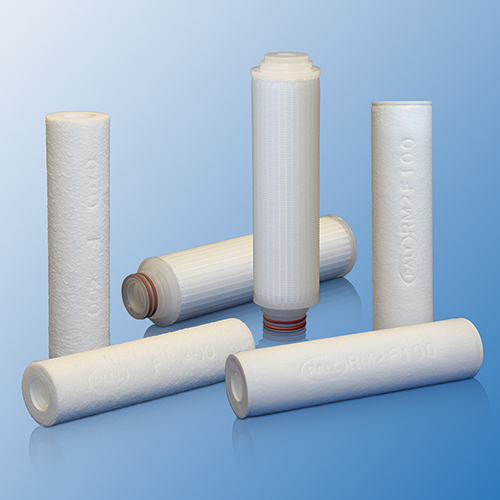

Profile® II Filter Cartridges

Designed for High Performance

Clarification and Particle Removal

Profile II cartridges are high efficiency depth style filters constructed of polypropylene. Constructed of polypropylene, with a continuously graded fixed pore structure, these cartridges provide pre- and final filtration within the same cartridge resulting in lower overall filtration and disposal cost. The Profile II filter cartridges provide a removal efficiency of >99.98% in compatible liquids with consistent filtration performance. | Features | Benefits |

| Fixed fiber matrix |

|

| Continuous pore size variation from coarse to fine |

|

| Cartridge | |

| Available in multiple configurations | Easy to integrate into existing lines |

| Polypropylene construction with no adhesives or surfactants | Broad chemical compatibility |

Food Contact Compliance

Please refer to the Pall website foodandbev for a Declaration of Compliance to specific National Legislation and/or Regional Regulatory requirements for food contact use.

Materials of Construction

| Media | Polypropylene |

| Core | Polypropylene |

| AB Style Cartridges Only | |

| Cage, End Cap and Fin End | Polypropylene |

| Adaptor | Polypropylene with a stainless steel reinforcing ring |

| O-ring Seal | Ethylene propylene rubber or silicone elastomer |

| RMF Style Cartridges Only | |

| Elastomeric End Cap and Seal | Thermoplastic elastomer |

Operating Characteristics in Compatible Fluids1

| Maximum Differential Pressure2 (Forward) | Operating Temperature |

| 4 bard (60 psid) | 30 °C (86 °F) |

| 3 bard (50 psid) | 50 °C (122 °F) |

| 2 bard (30 psid) | 70 °C (158 °F) |

| 1 bard (15 psid) | 82 °C (180 °F) |

| 0.3 bard (5 psid)3 | 125 °C (257 °F) |

1 Fluids which do not swell, soften or adversely affect any of the filter components.

2 In forward direction. Recommended change-out differential pressure is 2.4 bard

(35 psid), provided the maximum differential pressure (based on temperature) is

not exceeded.

3 AB style only

Sterilization and Sanitization5

| Method | Temperature | Cumulative Time |

| in situ Steam Sterilization | 125 °C (257 °F) | 10 hours |

| in situ Hot Water Sanitization | 80 °C (176 °F) | |

5 For applications requiring in situ sterilization or sanitization Pall recommends the

use of Code 7 adaptors to ensure filter sealing after cooling. Cartridges should

be cooled to system operating temperature prior to use. If RF or RMF elements

are heated in situ and cooled by a difference of more than 20 °C (36 °F), sealing

of the element may be marginal, depending on the type of sealing mechanism

used in the filter housing.

Typical Flow Rates4

It is recommended that the Max. Flow rate be selected such that the clean element pressure drop does not exceed 0.7 bar (10 psid) for optimal assembly life. Please contact Pall for optimized sizing.

4Typical initial clean media ØP 254 mm (10") element, water at 20 °C (122 °F), viscosity 1 cP,multiply the delta p by the viscosity.For assistance with filter assembly, sizing and housing selection, contact your local Pall representative.

Quality

- Cartridges produced in a controlled environment

- Manufactured according to ISO 9001:2008 certified Quality Management System

Table 1 - Nominal Length

| Code | Length |

| AB, RF and RMF Styles Only | |

| 1 | 254 mm (10 in.) |

| 2 | 508 mm (20 in.) |

| 3 | 762 mm (30 in.) |

| 4 | 1016 mm (40 in.) |

| RF Style Only | |

| 01 | 25.4 mm (1 in.) |

| 05 | 127 mm (5 in.) |

| 09 | 228.6 mm (9 in.) |

| 39 | 990.6 mm (39 in.) |

| RF and RMF Styles only | |

| 29 | 736.6 mm (29 in.) |

Table 2 - Liquid Removal Rating6

| Grade | Removal Rating (μm) at 99.98% Efficiency (ß-5000) | Removal Rating (μm) at 90% Efficiency (ß-10) |

| 005 | 0.5* | <0.5* |

| 010 | 1.0 | <0.5* |

| 030 | 3.0 | <1.0* |

| 050 | 5.0 | 2.0 |

| 100 | 10.0 | 6.5 |

*Extrapolated value

6 Profile II filter cartridge liquid retention ratings up to 20 micron are based on a

modified OSU-F2 single pass test in an aqueous medium. Oil is used as the

test medium for the 40 micron grade. Asterisks indicate extrapolated values.

Profile II filter cartridge liquid retention ratings are based on ANSI B93.31.73 modified for single pass testing in an aqueous medium.

Table 3 - Adaptor

| Code | Description |

| 3 | SOE - single open end with flat closed end and external 222 O-rings |

| 7 | SOE - single open end with fin end, 2 locking tabs and external 226 O-rings |

| 8 | SOE - single open end with fin end and external 222 O-rings |

| 28 | SOE - single open end with fin end, 3 locking tabs and external 222 O-rings |

Code 3, 7, 8 and 28 may be available in selected grades, confirm code availability with your Pall representative

Table 4 - O-ring Seal7

| Code | Description |

| H4 | Silicone Elastomer |

| J | Ethylene Propylene Rubber |

7 AB style configurations only

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.