Save money with the Pall portable purifier

Water in hydraulic, lubrication, power transmission and insulating fluids adversely affects fluid performance and is a threat to system reliability.The Pall HNP022 purifier solves the problem and unlike centrifuges and coalescers, it removes both free and dissolved water and gases.

Features - Water, Gas and Particulate Removal

- The HNP fluid conditioning purifier removes:

- 100 % free water and as much as 90 % of dissolved water.

- 100 % of free and entrained gases and up to 80 % dissolved gases

- Fine particulate, using a high performance filter element

- Simple automated operation

- In-built water sensor

- Fully portable for multiple site application

Benefits - Reduced Maintenance Costs

- High performance water, gas and particulate removal leads to……

- Extension of fluid service life

- Minimized corrosion within systems

- Reduced fluid disposal

- Low operating costs

- Increased equipment reliability

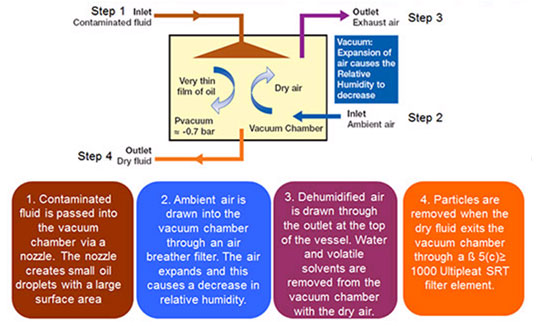

How Does it Work

Vacuum dehydration is the most effective method of water removal at minimum cost and ease of use. Unlike other methods it removes both free and dissolved water and without significantly altering the properties of the oil.

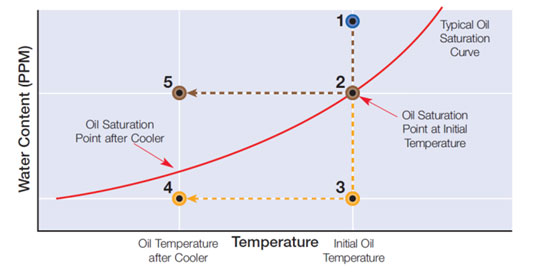

Removing free water is never enough!

- Initial water content is above saturation (free water).

- Maximum water removal capability of “free water removal” devices (coalescers, centrifuges, etc.) is to the oil’s saturation point.

- Water content achieved with mass transfer dehydration is significantly below the oil’s saturation point.

- Water content achieved with mass transfer dehydration remains below the oil’s saturation point even after oil is cooled by the system heat exchanger. This prevents the formation of free water which is detrimental to fluid system components and the fluid.

- If only free water is removed at initial temperature, when oil is cooled the amount of free water in the oil can increase significantly.

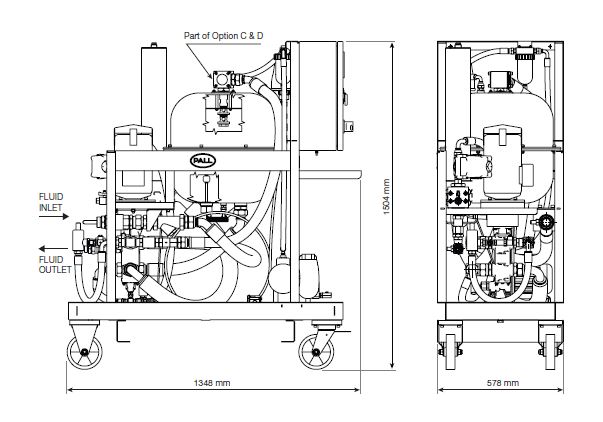

| Dimensions: | 1348 mm x 578 mm x 1504 mm |

| Dry mass: | 250 kg (551 lb) |

| Inlet/Outlet connections: | See table 3 below |

| Max. Recirculation Flow rate: | 25 L/min (6.6 US gpm) |

| Water removal rate*: | 26 L/day (6.8 US gpd) |

| Inlet pressure: | 1.5 barg (21.8 psi g) maximum |

| System back pressure: | 4.6 barg (66.7 psi g) maximum |

| Fluid temperature: | +10 ºC (50 °F) to +70 ºC (158 °F) |

| Fluid viscosity: | 700 cSt maximum |

| Operating vacuum: | -0.6 bar g (18” Hg) to -0.9 bar g (27” Hg) [adjustable] |

| Power supply: | See Table 1 |

| Total Motor power: | 2.22 kW maximum |

| Materials of Construction | |

| Base frame: | Carbon Steel, painted |

| Vessel: | 304 Stainless steel |

| Hydraulic fittings: | Zinc plated carbon steel |

| Control box: | Carbon steel, painted |

| Hydraulic hoses and seals: | Fluorocarbon |

Note: Pall fluid conditioning purifiers comply with all applicable EC directives and bears the CE mark.

HNP022 Performance

The HNP Oil purifier is designed to reduce and maintain the water content in a fluid system to below the saturation level of the system fluid ( < 300 ppm for a typical mineral oil). However, where a significant large water ingress occurs, the HNP022 can remove up to 12 gallons (45L) per day. The actual water removal rate depends on many variables, including system design, oil type, temperature, viscosity, water content, emulsion stability, and additives.Purifier

P/N: HNP023 [Table 1/Code 1][Table 1/Code 2] Z [Table 2][Table 3][Table 4][Table 5]

Note: Z indicates fluorocarbon seals and chlorinated polyethene hoses are standard. Other options are available; contact Pall.

Please select only from the following list of standard purifier options:

| HNP023S3ZCPENA HNP023S3ZCPENB HNP023S3ZCPENC HNP023S3ZCPEND HNP023S3ZCPDEA HNP023S3ZCPDEB |

HNP023S3ZCPDEC HNP023S3ZCPDED HNP023S3ZCPFRA HNP023S3ZCPFRB HNP023S3ZCPFRC HNP023S3ZCPFRD |

HNP023S3ZCPITA HNP023S3ZCPITB HNP023S3ZCPITC HNP023S3ZCPITD HNP023T3ZCPENA HNP023T3ZCPENB |

|||

Table 1 - Standard Voltage/Frequency Options

| Code 1 | Voltage | Code 2 | Frequency | Control Voltage |

| S | 400 Vac | 3 | 50 Hz, 3Ø | 24 Vdc |

| T | 415 Vac | 3 | 50 Hz, 3Ø | 24 Vdc |

Standard voltages only listed. Other voltages will be available on request - price and lead time will be provided on application.

Table 2 - Mounting Options

| Code | Mounting Type |

| C | Castor - Ø6”, 2 x fixed / 2 x swivel |

Table 3 - Process Port Connection Options

| Code 1 | Type | Inlet | Outlet |

| P | Parallel | G1 ½ male to ISO228 c/w bonded seal surface |

G1 male to ISO228 c/w bonded seal surface |

Table 4 - Language Options

| Code | Language |

| DE | German |

| EN | English |

| FR | French |

| IT | Italian |

Table 5 - Optional Factory Fitted Kits

| Code | Kit |

| A | No optional kit(s) fitted |

| B | 5m electrical cable, socket and plug, in accordance with IEC60309 to electrically connect the purifier |

| C | Gauge points, inlet and outlet pressure gauges and an inlet sight flow indicator to allow fluid condition and pressures to be monitored |

| D | Both kits B and C |

Replacement filter element P/N: UE310AZ20Z (ß3(c) >2000)

Other filter ratings available on application

Replacement Air Breather P/N: HC0293SEE5

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.