The RCA222 Differential Pressure (ΔP) Transducer is the latest monitoring device for use with Pall filter assemblies. It provides continuous, reliable, real time data of filter service condition to give users increased control of their fluid system maintenance procedures.

The RCA222 ΔP transducer senses the differential pressure across an in-service filter element and transmits the reading as a 4-20mA analogue signal, interpreted as a value of remaining filter life.

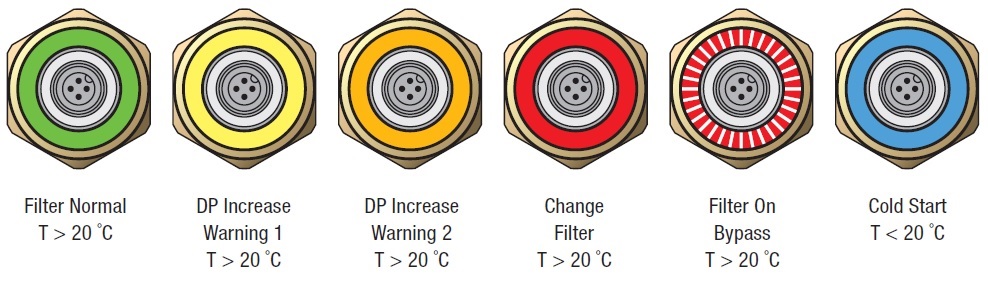

In addition it has two independent switched outputs set to 75% and 100% of filter service life to give an initial warning (75%) that the filter element will shortly need replacing, and a final warning (100%) that a replacement filter element is needed. This helps accommodate filter changes into planned maintenance schedules.

The ‘plug and play’ transducer is designed to fit all standard Pall threaded indicator ports, regardless of filter age, for applications rated up to 450 bar.

- Provides a more automated, continuous method for monitoring filter service life

- Sudden changes in filter condition can help detect potentially damaging operating conditions, enabling the operator to take corrective action before failure occurs

- No manual on-site checking of filter status required

- Transducer thermal lockout (< 20 ºC) ignores signals received before normal operating temperature is reached, ensuring readings are relevant

- Available in a range of standard differential pressures to suit the Pall filter housing bypass setting the transducer is intended to be used with

Technical Information

| Maximum operating pressure: | 450 bar |

| Pressure fatigue rating: | 0-400-0 bar >1 x 106 |

| Proof pressure: | 675 bar |

| Burst pressure (typical): | 1100 bar |

| Number of cycles (Mechanical): | 1 x105 |

| Operating Temperature: | -25°C(-13°F) to 85°C(185°F) |

| Minimum Ambient Temperature: | -40°C (-40°F) |

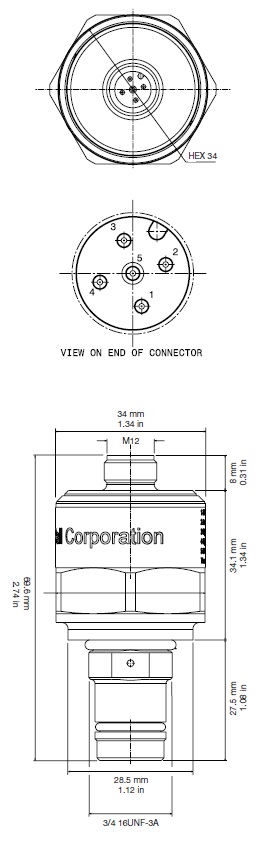

| IP rating: | IP65 with mating connector to M12-5 to IEC 61076-2-101 socket plug assembly. |

| Connector: | PA6, 6-M12-5 PIN to IEC 61076-2-101. |

| 4-20 mA & Modbus: | PA6, 6-M12 5 Pin |

| LED Option: | 6-M12 4 Pin, both to IEC 61076-2-101 |

Materials of construction

| Body, piston, spring retainer: | Brass |

| Spring: | Stainless Steel |

| Seals: | Fluorocarbon |

| Tightening torque setting: | 50-60 Nm. |

Electrical switch ratings

24 VDC PNP Maximum load 0.4A normally open, analogue output 4-20mA.

Automatic switch reset when differential pressure is reduced.

Thermal lockout T° = 20°C (68°F) Note if T < T° Digital output 1 remains normally open, digital output 2 remains normally open and analogue output remains at 4mA.

Analogue output remains at 4mA until a minimum of 25% of differential pressure range has been exceeded (dead band).

|

|

Indicator Part Numbers:

| 4-20 mA Output RCA222ZK2011 RCA222ZK4024 RCA222ZK4034 RCA222ZK8069 |

Modbus Output RCA222ZK20M RCA222ZK40M RCA222ZK80M |

LED Output RCA222ZK20LED11 RCA222ZK40LED24 RCA222ZK40LED34 RCA222ZK80LED69 |

| Code | Differential Pressure Range |

| K20 | 0.3 - 2.0 bard (5-29 psid) |

| K40 | 0.5 - 4.0 bard (8-58 psid) |

| K80 | 1.0 - 8.0 bard (15-116 psid) |

| Code | Switch Output Setting |

| 11 | 1.1 bar (16 psid), with K20 only |

| 24 | 2.4 bar (35 psid), with K40 only |

| 34 | 3.4 bar (50 psid), with K40 only |

| 69 | 6.9 bar (100 psid), with K80 only |

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.