Features

- Flows to 1500 L/min (400 US gpm)

- Pressures to 28 bard (400 psi)

- Port size 3" and 4"

- Unique Ultipleat (laid-over pleat) filter medium pack

- Coreless, cageless element configuration

- Pall Stress-Resistant Technology (SRT) Media

- In-to-out filter element flow path

The UR629/49/69 Series is a Preferred Product Line utilizing Stress-Resistant Technology. Please See Ordering Information for available options

All replacement filter elements, differential pressure indicators and sealkits remain available for this series. See ‘Ordering Information’ tab above for details of spares.

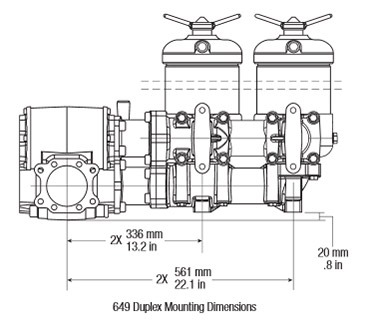

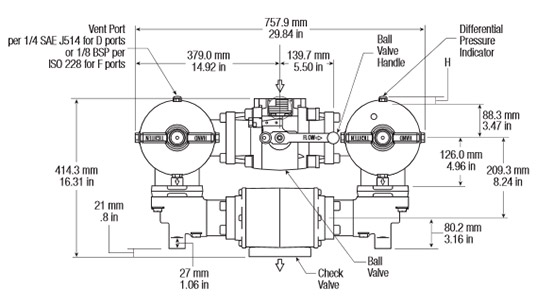

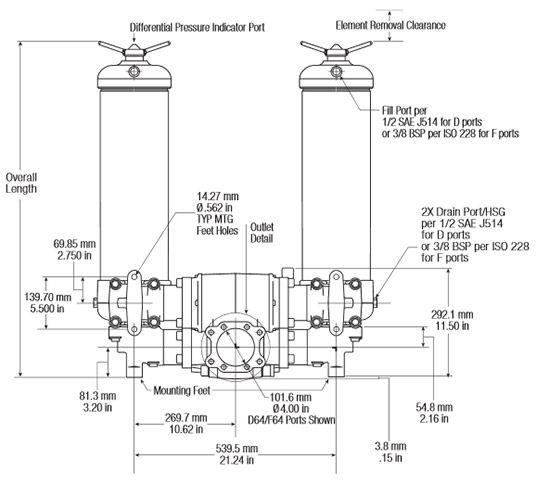

Dimensional Drawings

Dimensions in mm (inches)

Contact Pall for dimensions for UR669 and UR689 housings.

| Length Code |

Overall Length mm (in.) |

Element Removal Clearance mm (in.) |

Empty Weight kg (lb) |

| 20 | 897.1 (35.32) | 442.7 (17.43) | 88.9 (196) |

| 40 | 1405.1 (55.32) | 950.7 (37.43) | 112.5 (248) |

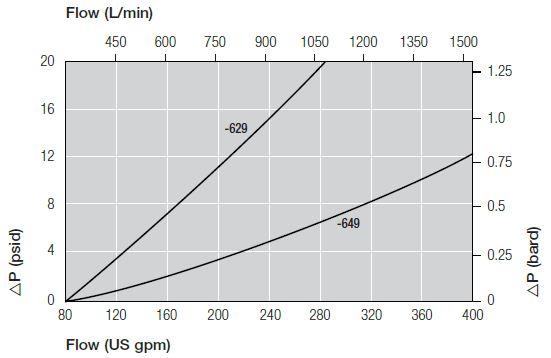

Pressure Drop Information

Housing pressure drop using fluid with 0.9 S.G.Housing pressure drop is directly proportional to specific gravity.

- Keeps fluids the cleanest, longest, for the greatest value

- Provides consistent, reliable, protection of system components over the full service life of the filter element

- Rapidly achieves and sustains required fluid system cleanliness

- Delivers maximum filter capacity in the smallest footprint

- Prevents electrostatic discharge from damaging your filter and degrading your fluid

Element Pressure Drop

610 Series Filter Elements – bard/1000 L/min (psid/US gpm)| Length Code | AZ | AP | AN | AS | AT |

| 20 | 1.31 (0.072) | 0.56 (0.030) | 0.43 (0.023) | 0.31 (0.017) | 0.19 (0.011) |

| 40 | 0.70 (0.038) | 0.30 (0.016) | 0.23 (0.013) | 0.17 (0.009) | 0.10 (0.006) |

Multiply actual flow rate times factor in table below to determine pressure drop with fluid at 32 cSt (150 SUS), 0.9 S.G. Correct for other fluids by multiplying new viscosity in cSt/32 (SUS/150) x new S.G./0.9. Note: factors are per 1000 L/min and per 1 US gpm

Sample ΔP calculation

UR629 Series 40” length housing with F48 (3” SAE) split flange ports using AN grade media. Operating conditions 600 L/min flow rate using a hydraulic fluid of 50 cSt and specific gravity (s.g.) 1.2.

Total Filter ΔP= ΔP housing + ΔP element

= (0.45 x 1.2/0.9) bard (housing)

+ ((600 x 0.23/1000) x 50/32 x 1.2/0.9) bard (element)

= 0.60 (housing) + 0.29 bard (element)

= 0.89 bard (12.9 psid)

Section 1: Housing P/N: UR [Table A] [Table B] [Table C]

Note: Pall Athalon filter housings are supplied without filter elements or warning devices fitted. Never operate the filter unless a filter element is fitted and all warning device ports are sealed.Note:Z indicates fluorocarbon seals are standard. Other options are available;contact Pall. Housing P/N designates indicator port fitted with a plastic shipping plug.

| Table A | Table B | Table C |

| Table 1 | Tables 2, 3, 4 | Table 5 |

| 629C | D4820Z | A,G, or N |

| D4840Z | ||

| D6420Z | ||

| D6440Z | ||

| F4820Z | ||

| F4840Z | ||

| F6420Z | ||

| F6440Z | ||

| 649C | D4840Z | A,G, or N |

| D6440Z | ||

| F4840Z | ||

| F6440Z | ||

| 669C | D6440Z | A or G |

| F6440Z | ||

| 689C | D6440Z | A or G |

| F6440Z | ||

Table 1: No. of Filter Housings

| Code | No. of Housings |

| 629 | 2 (1 per side) |

| 649 | 4 (2 per side) |

| 669 | 6 (3 per side) |

| 689 | 8 (4 per side) |

Table 2: Housing Port Options

| Code | Port Style |

| D | Flange J518C code 61 |

| F | ISO 6162 split flange |

Table 3: Port Size

| Code | Port Style |

| 48 | 3” nominal |

| 64 | 4” nominal |

Table 4: Housing Length and Seal Options

| Code | Length and Seal Material |

| 20Z | 20” nominal length, fluorocarbon seals |

| 40Z | 40” nominal length, fluorocarbon seals |

Table 5: Bypass Valve and Service Options

| Code | Bypass Valve and Service Type |

| A | 1.7 bard (25 psid) bypass valve, cover service |

| G | 4.5 bard (65 psid) bypass valve, cover service |

| N | No bypass valve |

Seal Kit P/N: UR629CSKZ

*Other seal material options are available; Contact Pall.

Section 2 Element P/N: UE 610 [Table 6] [Table 3]

Note: Z indicates fluorocarbon seals are standard.Other options are available; contact Pall.

Table 6: Filter Element Options

| Code | ßx(c) ≥2000 based on ISO 16889 | CST Rating* |

| AZ | 3 | 07/04/01 |

| AP | 5 | 11/08/03 |

| AN | 7 | 13/09/04 |

| AS | 12 | 15/11/06 |

| AT | 25 | 16/14/08 |

* CST: Cyclic Stabilization Test to determine filter rating under stress conditions, based on SAE ARP4205

Section 3 (At least one Differential Pressure Indicator or ‘B’ type blanking plug must be ordered for each filter tower)

Differential Pressure Indicator P/N: RC [Table 7] Z [Table 8] ZNote: If no differential pressure indicator is selected, ‘B’ type blanking plug (P/N HC9000A104Z) must be ordered separately and fitted to replace the plastic shipping plug in each filter tower.

For typical installations, only 2 indicators are required - only one housing per side requires an indicator. Replace other shipping plugs with blanking plugs.

Note :Z indicates fluorocarbon seals are standard. Other options are available; contact Pall.

Table 7: Indicator Options

| Code | Brass Option indicator |

| A218M | Electrical switch (SPDT) with Hirschmann connector |

| A218R | Electrical switch (SPDT) with Hirschmann connector with Red and Green LED indicators |

| A219D | Visual indicator |

Other options are available; contact Pall.

Table 8: Indicator Pressue Setting Option

| Code | Valve |

| 084 | For ‘A’ Valve Option - Housings (1.1 bard - 16 psid) |

| 091 | For ‘G’ and ‘N’ Valve Options - Housings (3.5 bard - 50 psid) |

Other setting options are available; contact Pall.

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.