High Flow Filtration Technology Available as a Rental Skid: Simplex 4 Element Filter Skid (Skid can be converted to a liquid/liquid coalescer)

Please Note: The following information is provided to support existing users of Pall Cleanliness Cabinets (PCCs) for technical reference and order of consumables and spare parts. The complete cabinet assemblies are no longer available to purchase.

Effectively Separate Liquid/Liquid Dispersions on Medium, Coarse, or Higher Solids Emulsions

Description

The AquaSep EL system is a multiple-stage system starting with filtration to remove particulate matter, followed by either a one-stage horizontal coalescer or a two-stage integrated vertical coalescer/separator stack to separate the two liquid phases. AquaSep EL coalescers will remove free water to a level as low as 15 ppmv1 and be effective over a wide range of conditions such as inlet liquid contaminant concentration as high as 10% and interfacial tension less than 20 dynes/cm.

Table 1: Coalescer Selection Guide

| Process Condition | Recommended Product |

| The dispersed phase fluid is aqueous and a horizontal footprint is acceptable | AquaSep EL coalescer in a horizontal housing without separator |

| The dispersed phase fluid is oil and the continuous phase fluid is aqueous | |

| The dispersed phase fluid is aqueous and minimal footprint is required | AquaSep EL coalescer/separator stack in a vertical housing |

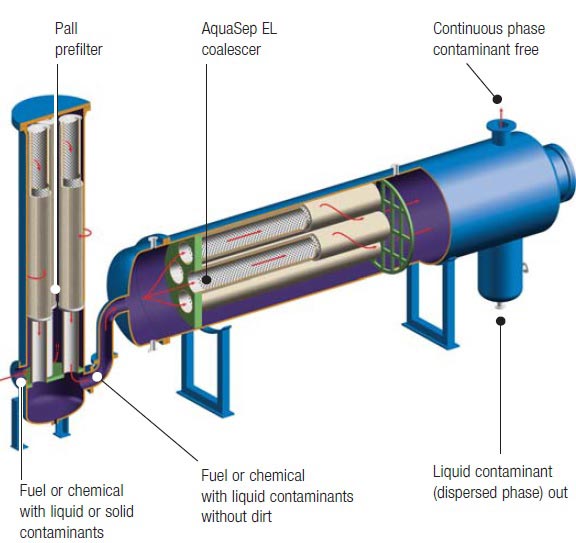

AquaSep EL Coalescer— Horizontal Housing Configuration

In a horizontal housing, the liquid/liquid mixture enters the coalescing element and flows inside-to-outside, small liquid dispersed phase droplets suspended in the continuous phase come together, or coalesce, as the mixture moves through the AquaSep EL coalescer. The large coalesced droplets of the dispersed phase separate by gravity in the horizontal housing and are removed. The size of the housing is a function of the flow rate, IFT, viscosity, and specific gravity of the liquids.

Figure 3: AquaSep EL Liquid/Liquid Separation System with Coalescer in a Horizontal Housing with a Prefilter

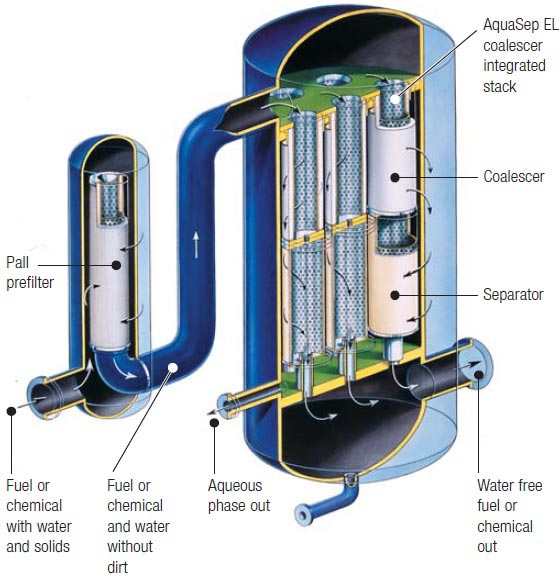

AquaSep EL Coalescer/Separator Stack— Vertical Housing Configuration

The liquid/liquid mixture enters the coalescing element and flows inside-to-outside. Small liquid droplets suspended in the continuous phase come together, or coalesce, as the mixture moves through the coalescer medium.

Contaminant-free liquid and large droplets of the dispersed phase flow toward the separator located directly below the coalescer stage. The flow is outside- to- inside. The separator medium is hydrophobic preventing the aqueous phase from entering the separator. Only the non-aqueous continuous phase fluid flows through the separator. The two liquids are removed by separate drain connections.

Figure 4: AquaSep EL Liquid/Liquid Separation System with an Integrated Coalescer/Separator Stack in a Vertical Housing with a Prefilter

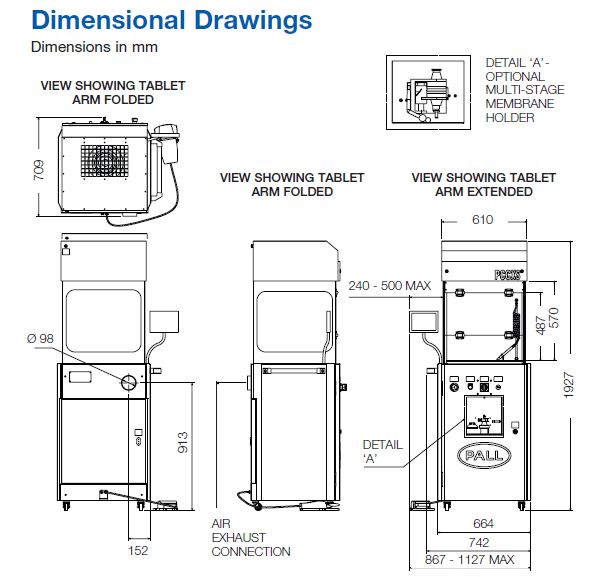

(W x D x H)820 x 709 x 1983 mmWorking area:

(W x D x H)600 x 600 x 500 mmWeight:175 kg (385 lb) approxMaterials:Working area: Sink: Polished stainless steel 304L Enclosure: Perspex® Acrylic or equivalentPower supply:230 V – 50 Hz, single phasePLC:ProfacePower consumption1.3 kW (without ultrasonics)Reservoir (solvent):13 L max (3.4 USg)Rinsing flow rate:

(Adjustable)5 L/min max. (1.3 USgpm) Solvent pen adjustableRinsing pressure:2.8 bar max (41 psi)

The PCCXS series cabinets comply with the European Machinery Directive 2006/42/EC, Low voltage 2006/95/CE, and Electromagnetic compatibility 2004/108/CE and is fully CE compliant.

Technical information

Technical information

Table 1: Voltage Option

| Code | Description |

| 1 | 110V / 50 & 60Hz, single phase |

| 2 | 230V / 50 & 60 Hz, single phase |

Table 2: Membrane Option

| Code | Description |

| S | Single stage membrane holder |

| M | 230V / 50 & 60 Hz, single phase |

Table 3: Ultrasonic Option

| Code | Description |

| OMIT | No Ultrasonic transducer |

| US 100 | 100W Ultrasonic agitation power |

Table 4: Accessories

| Code | Description |

| PCCXSBU | Bowl for ultrasonic analysis (perforated bowl including |

| PCCXSMP | Analysis mounting plate (perforated PEHD plate to hold test component during nozzle spraying) |

| PCCXSSG | Splashback guard (guard to avoid splashes during nozzle spraying) |

Analysis Membranes for Component Cleanliness Assessments

- Ratings from 5 μm to 100 μm

- Materials: Nylon

see product datasheet M&EPCCMEMENa

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.