Features

- Flows to 910 L/min (250 US gpm)

- Pressures to 420 bard (6100 psid)

- Port size 2"

- Ultipor® III filter medium pack

- Out-to-in filter element flow path

The 9900/01/04 Series is a Preferred Product Line utilizing Ultipor® III filter medium. The 9900 and 9904 Series are no longer available as standard products. See Ordering Information for the list of available 9901 Series housing part numbers.

All replacement filter elements, differential pressure indicators and sealkits remain available for this series. See 'Ordering Information' tab above for details of spares.

Notes and Specifications

Filter Housing

- Fatigue Pressure Rating

207 bar (3000 psi) per NFPA T2.6.1 R2-2001 Cat C/90

(1 million cycles) - Typical Burst Pressure:

1,035 bar (15,000 psi) - Filter Element Collapse Pressure:

10 bard (150 psid) - Fluid Compatibility:

Compatible with all petroleum oils and most water glycols, water-oil

emulsions, and synthetic hydraulic and lubricating fluids - Temperature Range:

-29 ˚C to 120 ˚C (-20 ˚F to 250 ˚F)

60 ˚C (140 ˚F) maximum in HWCF or water glycols - Bypass Valve Setting:

3.4 bard (50 psid) - Indicator Pressure Setting:

2.4 bard (35 psid) - Housing Materials of Construction:

Ductile iron head and cover; steel tube

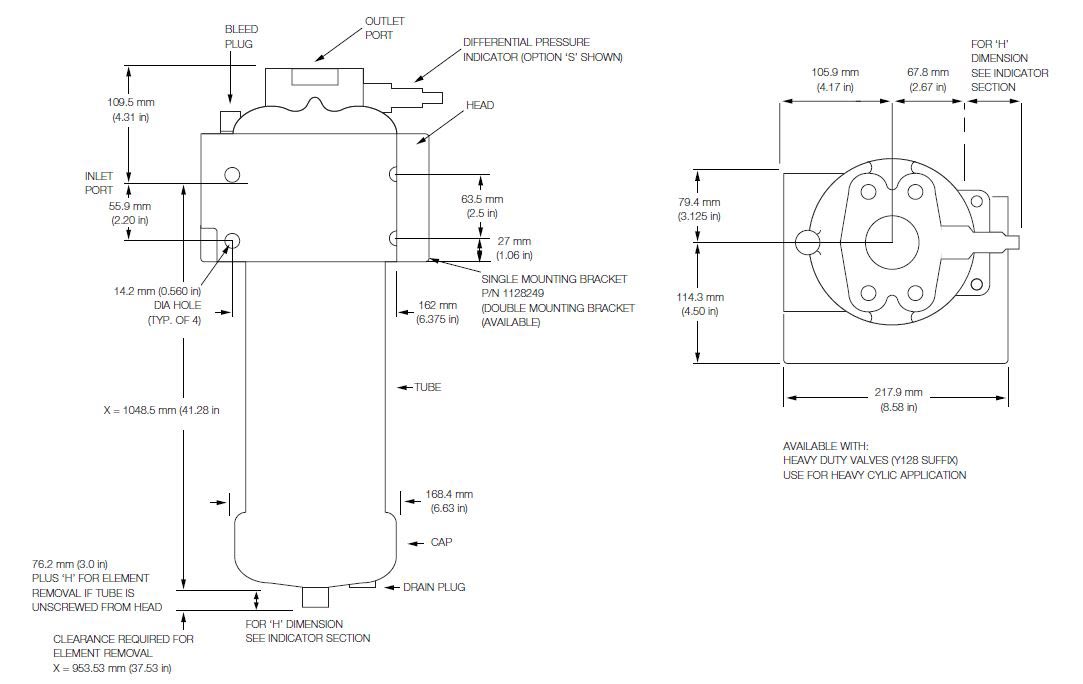

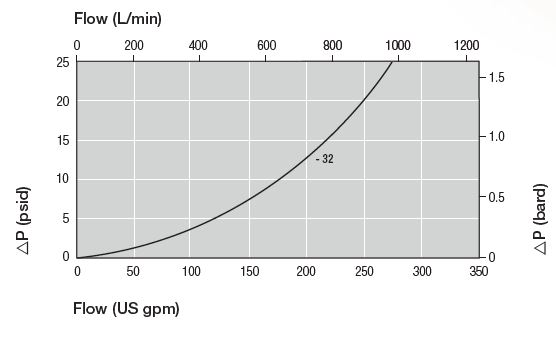

Pressure Drop Information

Housing pressure drop using fluid with 0.9 S.G. Housing pressure drop is directly proportional to specific gravity.

Element Pressure Drop

Multiply actual flow rate times factor in table below to determine pressure drop with fluid at 32 cSt (150 SUS), 0.9 S.G. Correct for other fluids by multiplying new viscosity in cSt/32 (SUS/150) x new S.G./0.9.

9400 Series Element DP Factors (psid/US gpm)

| Length Code |

CZ | CP | CN | CS | CT |

| 39” | 0.06 | 0.03 | 0.02 | 0.02 | 0.01 |

For new installations, select one complete part number from each section below

Section 1 Housing P/N:

Note: Pall filter housings are supplied without filter elements or filter change out warning devices. Never operate the filter housing unless a filter element is fitted and all warning device ports are sealed.

Housing part number designates indicator port is fitted with a plastic shipping plug.

| Part Number |

| HZ9900D32XB1 |

| HZ9900E32XB1 |

| HZ9900F32XB1 |

| HZ9900G32XB1 |

| HZ9900G32 XC1 |

| Part Number (Description) Breakdown |

| HZ = housing with fluorocarbon seals |

| 9900 = 9900 series housing |

| D32 = 2” Flange ports SAE J518C code 61 (207 bar/3000 psi max pressure) |

| E32 = 2” Flange ports SAE J518C code 62 (414 bar/6000 psi max pressure) |

| F32 = 2” ISO 6162 split flange ports (250 bar/3625 psi max pressure) |

| G32 = 2” ISO 6162 split flange ports (400 bar/5800 psi max pressure) |

| X = 39” nominal length |

| B = 3.4 bard (50 psid) bypass valve |

| C = 3.4 bard (50 psid) bypass valve with reverse flow valve |

| 1 = 1 indicator warning device port |

Section 2 Element P/N: HC9400F [Table 1] 39 [Table 2]

Table 1: Filter Performance Ratings

| Code | ßx(c) ≥1000 based on ISO 16889 |

ISO Code Rating per Stress-Resistance Test (80% Δp)* |

| CZ | 3 | 10/08/03 |

| CP | 5 | 12/09/07 |

| CN | 7 | 14/11/06 |

| CS | 12 | 15/11/06 |

| CT | 22 | 16/14/08 |

*based on 60 psid terminal pressure drop

Table 2: Seal Options

| Code | Description |

| Z | Fluorocarbon |

| H | Nitrile |

Section 3 Differential Pressure Indicator P/N: RC [Table 3] Z 090 Z [Table 4]

Note: If no Differential Pressure Indicator is selected, ‘B’ type blanking plug (P/N HC9000A104Z) must be ordered

Note: Z indicates fluorocarbon seals are standard. Other options are available; contact Pall.

Table 3: Indicator Options

| Code | Brass Option Indicator |

| A218M | Electrical switch (SPDT) with Hirschmann connector |

| A218R | Electrical switch (SPDT) with Hirschmann connector with Red and Green LED indicators |

| A219D | Visual indicator |

| Code | Stainless Steel Option Indicator |

| 778N | Visual filter with the thermal lockout |

| 861C | Electrical switch (SPDT) with Hirschmann connector |

| 771B | Electrical switch (SPDT) with 3-pin |

Table 4: Differential Pressure Indicator Material

| Code | Description |

| Omit | If Brass Indicator is selected in Table 3 |

| SS | If Stainless Steel Indicator is selected in Table 3 (recommended for high-pressure applications with pressure > 200 bar (3000 psi) |

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.