Pall Retrofit Coalescers and After Filters for SPX Flow/Pneumatic Products and Other Manufacturers

Description

In order to ensure that clean, dry compressed air gets to pneumatic components plants often use air dryers. These dryers use desiccant to pull moisture from compressed air. Typical life of desiccant is 3-5 years, with desiccant material replacement costing up to tens of thousands of dollars.

To maximize desiccant life, liquid/gas coalescers are typically installed upstream of the dryer to remove water and oil aerosols. In addition, After Filters are installed downstream of the dryer to capture particulates generated as the desiccant ages.

Pall Corporation, a leader in coalescing technologies, now offers replacement coalescers and After Filters for users of SPX Flow/Pneumatic Products and other coalescer manufacturers.

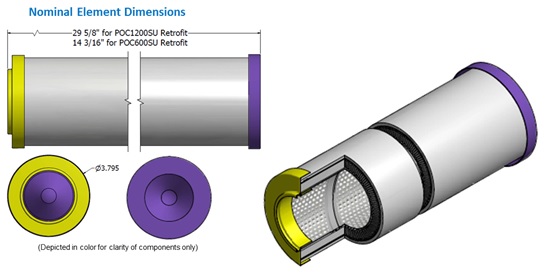

Pall-Fit Replacement Coalescers

Featuring Pall’s SeprasolTM Plus coalescer medium, our liquid/gas coalescers remove liquids and solids from high flow gas streams that contain high concentrations of liquids. Pall’s SepraSol Plus liquid/gas coalescers receive our proprietary full element oleophobic/hydrophobic treatment. Chemically treating the coalescer lowers the surface energy of the media and promotes rapid drainage of the coalesced liquids. This significantly increases the amount of liquid per square foot of media the coalescer can handle, and optimizes liquids removal in the existing housing size. Added benefits of the chemical treatment include lower saturated pressure drop for reduced operating costs, and rapid recovery from liquid slugs to protect the desiccant from upstream upsets.

Separating aerosols before entering the dryer maximizes desiccant life and helps prevent damage to the dryer inlet valve. The result is reduced desiccant replacement costs and extended valve life for significant savings in material, labor and downtime costs.

| Feature | Benefit |

| SepraSol Plus media pack |

|

| Proprietary Oleophobic/Hydrophobic element treatment |

|

| High-effective filtration area |

|

| High efficiency media |

|

| 304 Stainless steel hardware |

|

Specifications

- Coalescer Medium: Seprasol Plus fully treated glass fiber pleated medium

- Surface Area: up to 30% greater surface area for long service life

- Efficiency: 99.999% removal of 0.3 Micron Aerosols

- End Caps, Core and Cage: 304 Stainless Steel to prevent oxidation and maintain structural integrity

- Flow Direction: In to Out

- O-Ring: Viton

Pall-Fit Replacement After Filters

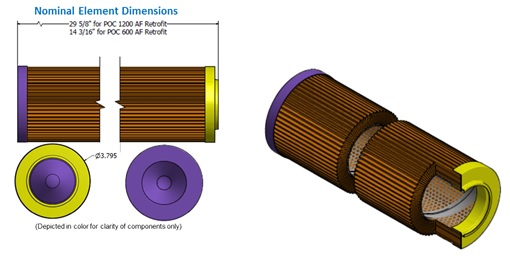

Pall’s high area After Filter cartridges have been designed specifically for use downstream of desiccant dryers. These long-life filters have up to 1.5X the area of other cartridges and have a 0.9 micron particle rating to capture abrasive dust particles coming off the dryer that can erode instruments, valve seats, air cylinders and pneumatic tools. Preventing particles from entering the stream means sustained equipment performance, longer component service life, and reduced maintenance and downtime costs.

Specifications

- Medium: Pleated Cellulose

- Rating: 0.9 Micron

- Flow Direction: Out-to-In

- End Caps and Core: 304 Stainless Steel

- O-Ring: Viton

- Maximum Temperature: 200°F*

*This element is designed for use downstream of heatless regeneration dryers. Please contact Pall for information on products designed for use downstream of heat-regenerated dryers.

Type

Ordering Information

| Manufacturer | Part Number | Product | Pall Retrofit P/N |

| SPX/Pneumatics | POC1200SU | Coalescer | RLG013PG430S0003V |

| SPX/Pneumatics | PPC1200SU | Coalescer | RLG013PG430S0003V |

| SPX/Pneumatics | POC600SU | Coalescer | RLG013PG414S0003V |

| SPX/Pneumatics | POS060SU | Coalescer | PFS4463ZMH13 |

| SPX/Pneumatics | POC1001SU | Coalescer | PFS1001ZMH13 |

| SPX/Pneumatics | POS1001SU | Coalescer | PFS1001ZMH13 |

| Parker | 6QP30-143X1 | Coalescer | RLG013PG414S0003V |

| Parker | 6QP30-295 | Coalescer | RLG013PG430S0003V |

| Filtersoft | Filtersoft | Coalescer | RLG013PG430S0003V |

| SPX/Pneumatics | PCC600AF | After Filter | RPF013PE414S0009V |

| SPX/Pneumatics | PCC1200AF | Aftre Filter | RPF013PE430S0009V |

| SPX/Pneumatics | PCC1001AF | After Filter | MCS1001ECH13 |

| SPX/Pneumatics | PCS1001AF | After Filter | MCS1001ECH13 |

| SPX/Pneumatics | PCC4463AF | After Filter | MCS4463ECH13 |

| SPX/Pneumatics | PCC060AF | After Filter | MCS4463ECH13 |

| Parker | 3PP30-295X1 | After Filter | RPF013PE430S0009V |

| Parker | 3PP30-143X1 | After Filter | RPF013PE414S0009V |

| Connector to stack 2 MCS1001 elements | T11093030 | ||

Summary

Pall’s new retrofit products allow users of other manufacturers’ elements to benefit from Pall technology without the need to replace the existing housing/vessel. Pall retrofit products are direct replacements for existing elements, offering the performance and value you have come to expect from Pall.

Advantages of Pall Technology

Pall’s filter media and element designs bring together industry leading technologies and advanced manufacturing processes to deliver excellent performance and value in each and every element.

Global Presence – Local Support

Pall is a global company with offices in Asia-Pacific, Americas, Europe, and the Middle East. This global presence gives us the ability to provide local commercial or technical support whenever or wherever there is a customer need.

Reviews

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.