Description

The Ultipleat®PC filter is specifically recommended for component parts cleaning applications where high flow rates, together with a 0.1 μm / 0.2 μm particle removal ratings, are required. The PTFE filter membrane is incorporated in a unique, crescent-shaped or laid-over pleat geometry to provide an increase in effective filtration area and service life.

| Features | Benefits |

| Ultipleat construction |

|

| PTFE and polypropylene materials |

|

| No surfactants or binder resins |

|

Specifications

| Materials of Construction | |

| Filter Membrane | PTFE |

| Support and drainage | Polypropylene |

| Core and cage | Polypropylene |

| End caps | Polypropylene |

| AB style cartridges only | |

| O-ring options | FEP encapsulated fluoroelastomer (standard), ethylene propylene, or fluoroelastomer |

| PUY style cartridges only | |

| Gasket options | Ethylene propylene, fluoroelastomer, polypropylene |

Removal Rating: 0.1 μm , 0.2 μm

Filter area: 0.23 m2 / 2.5 ft2

| Configurations | |

| Nominal length | 254 mm / 10 in. |

| Nominal diameter | AB: 70 mm / 2.75 in, PUY: 64 mm / 2.5 in. |

Operating Conditions1

Maximum operating temperature: 70 ˚C / 158 ˚F

| Maximum differential pressure | Operating Temperature |

| 0.55 MPa / 80 psi | 20 ˚C / 68 ˚F |

| 0.31 MPa / 45 psi | 70 ˚C / 158 ˚F |

1For compatible liquids

Performance

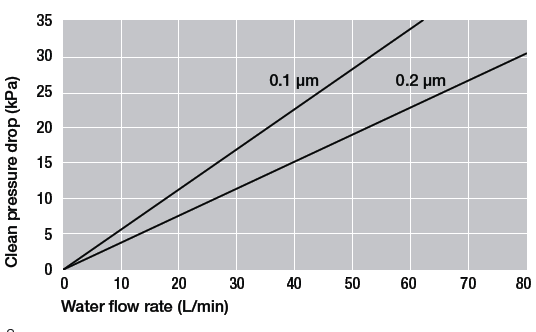

Pressure Drop vs. Liquid Flow Rate (Water, 20°C)2

2 For Liquids with a viscosity differing from water, multiply the pressure drop by the viscosity in centipoises.

Type

Filter Cartridges

Ordering Information

Part Numbers / Ordering Information

AB [1] PC [2] [3] [4]

PUY [1] PC [2] [5]

Table 1

| Code | Length (mm / in.) |

| 1 | 254 / 10 |

| 2 | 508 / 20 |

| 3 | 762 / 30 |

Table 2

| Code | Removal Ratings |

| 001 | 0.1 μm |

| 002 | 0.2 μm |

Table 3

| Code | O-ring Size |

| 3 | AS568A - 222 |

| 7 | AS568A - 226 |

Table 4

| Code | O-ring Seal |

| J | Ethylene propylene |

| H | Fluoroelastomer |

| H1 | FEP encapsulated fluoroelastomer3 |

Table 5

| Code | Gasket Seal |

| J | Ethylene propylene |

| H | Fluoroelastomer |

| Y1 | Polypropylene |

3 Standard O-ring for AB style filter cartridge

For availability of specific options and housing details, please contact your Pall Corporation representative

Reviews

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.