Ultipleat PKS filter cartridges are designed for high flow rate, aqueous applications required for 5G to the newest generation of liquid crystal display (LCD) processes. These filters can handle flow rates up to 250 L/min, thereby reducing system footprint and change-out costs. Ultipleat PKS filters are available in four filter media types; polypropylene, highly asymmetric hydrophilic polysulfone, polyethersulfone and PTFE, with removal ratings from 0.1 μm to 20 μm.

- Ideally suited for most LCD wet processing applications, such as developing, etching, stripping and DI water rinsing

- Broad choice of membranes and removal ratings, suitable for many different applications

- Patented, crescent-shaped pleat structure allows for high flow rates and long service life

- Compact design makes for efficient filter change-outs, thus reducing equipment down-time

Materials

- Media options:

- (I) Polypropylene

- (II) highly asymmetric, hydrophilic polysulfone

- (III) hydrophilic polyethersulfone

- (IV) PTFE

- Support and drainage: Polypropylene

- Core: Polypropylene

- End caps: Polypropylene

- Sealing options:

- Ethylene propylene (EPDM)

- Fluoroelastomer

- FEP encapsulated fluoroelastomer

- Kalrez1

1Kalrez is a registered trademark of E. I. du Pont de Nemours and Company.

Removal Ratings

- Polypropylene: 2 μm, 4.5 μm, 10 μm, 20 μm

- Highly asymmetric, hydrophilic polysulfone:0.03μm, 0.1 μm, 0.2 μm

- Hydrophilic polyethersulfone: 0.45 μm, 1.2 μm

- PTFE: 1 μm, 3 μm, 10 μm

Operating Conditions

- Maximum Operating Temperature:

- Polypropylene, highly asymmetric hydrophilic polysulfone, hydrophilic polyethersulfone: 80 °C / 176 °F

- PTFE: 85 °C / 185 °F

- Maximum Differential Pressure:

- 0.69 MPa @ 20 °C / 100 psid @ 68 °F

- 0.34 MPa @ 80 °C / 50 psid @ 176 °F

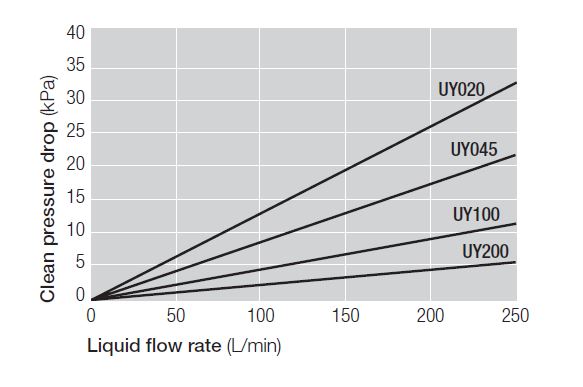

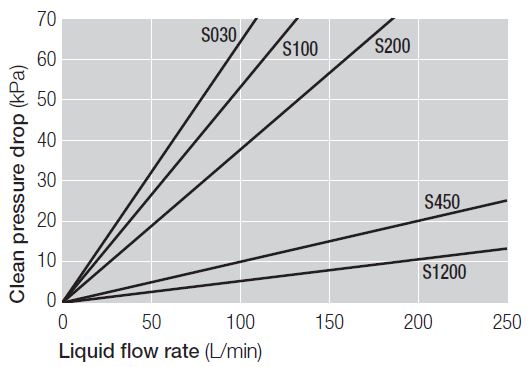

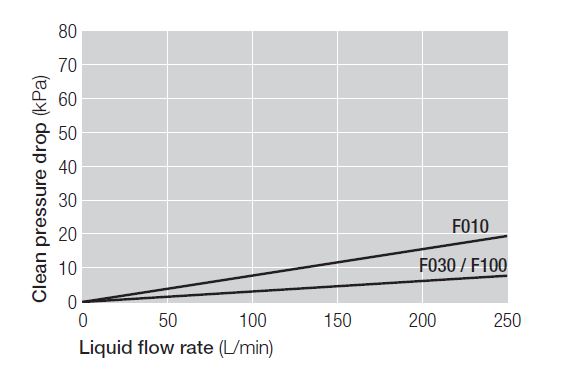

Typical Flow Characteristics - 1cP fluid, 20℃

Polypropylene

Highly Asymmetric Hydrophilic Polysulfone

Hydrophilic Polyethersulfone

PTFE

Filter Cartridges

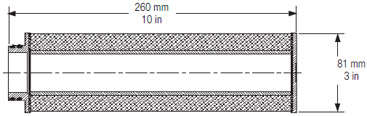

Dimensions (nominal)

UPK310 [1] [2]

Table 1| Code | Filter Media | Removal ratings (μm) |

| UY020 | Polypropylene | 2 |

| UY045 | 4.5 | |

| UY100 | 10 | |

| UY200 | 20 | |

| UY300 | 30 | |

| S030 | Highly asymmetric, hydrophilic polysulfone |

0.03 |

| S100 | 0.1 | |

| S200 | 0.2 | |

| S450 | Hydrophilic polyethersulfone | 0.45 |

| S1200 | 1.2 | |

| F010 | PTFE | 1 |

| F030 | 3 | |

| F100 | 10 | |

Table 2

| Code | O-ring materials |

| J | EPDM |

| H | Fluoroelastomer |

| H1 | FEP encapsulated fluoroelastomer |

| H11 | Kalrez |

Representative example part numbers

| (Polypropylene Media) | (Hydrophilic Polyethersulfone Media) |

| UPKS310UY020J | UPK310S450J |

| UPKS310UY045J | UPK310S1200J |

| UPKS310UY100J | |

| UPKS310UY200J | (PTFE Media) |

| UPK310F010H1 | |

| (Highly Asymmetric Hydrophilic Polysulfone Media) | UPK310F030H1 |

| UPK310S030J | UPK310F100H1 |

| UPK310S100J | |

| UPK310S200J | |

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.