Description

The Ultipleat High Flow Filter is designed for TFT LCD liquid applications, such as wet etching and cleaning. Its large diameter, inside out flow path and unique, high area, pleated construction allow for a long service life.1The filter is very economical due to its high flow capacity. Far fewer filters are thus required, compared to standard size cartridges.

1 Service life is dependent upon chemical compatibility and temperature.

Features and Benefits

- Large filter diameter, 152 mm / 6.3 in. nominal, equates to fewer cartridges and smaller housing footprint

- Easy filter change-out

- 249 mm / 9.8 in. and 526 mm / 20.7 in. lengths available

- High area pleated construction for low differential pressure and high dirt capacity

- PTFE and ECTFE medium for excellent etchant compatibility

- Long service life

- Inside out flow pattern further enables high flow rates

Specifications

Materials of Construction

| Components | Materials | ||

| Filter Medium | PTFE | ECTFE | |

| Removal Rating | 3 μm | 10 μm | |

| Support, drainage | Polypropylene | ECTFE | |

| Support core | Polypropylene | ECTFE | |

| End caps | Polypropylene (glass fiber filled) | ||

| O-ring | FEP encapsulated fluoroelastomer | ||

| Maximum Operating Temperature | 82 ˚C / 180 ˚F | ||

| Maximum forward differential pressure | 0.34 MPa @ / 50 ˚C 50 psi @ 122 ˚F | ||

| Housings | Ultipleat high flow plastic housing P/N: 1HFVV-09GF25H, 1HFVV-2GF41H (For availability of specific options and housing details, please contact your Pall Corporation representative.) | ||

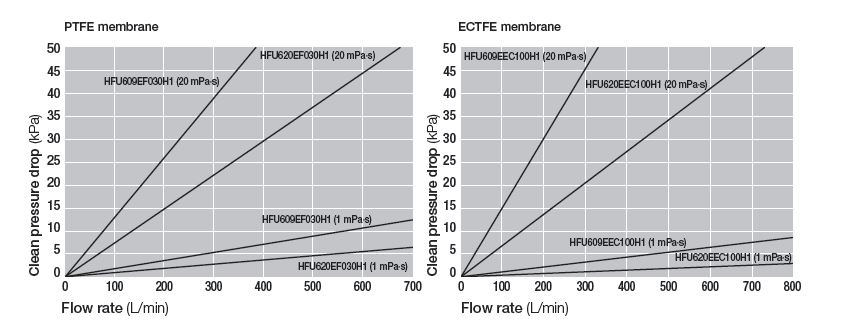

Pressure Drop vs. Liquid Flow Rate1

1 For liquids with viscosity differing from water, multiply the pressure drop by the viscosity in centipoise.

Since etchants can vary significantly, it is recommended that the filter be tested for compatibility at the service temperature to ensure long service life.

Type

Ordering Information

HFU6 [1] EF030H1

ECTFE membrane

HFU6 [1] EEC100H1

Table 1

| Code | Length |

| 09 | 249 mm / 9.8 in |

| 20 | 526 mm / 20.7 in |

Specifications and availability: The information provided in this literature was reviewed for accuracy at the time of publication. Product availability may be subject to change without notice. For current information, consult your local Pall distributor or contact Pall Corporation directly.

Reviews

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.