Description

Long Life Membrane Filtration

for Aqueous Ink Jet Inks

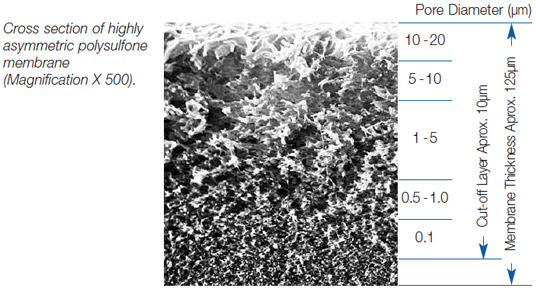

The Pall® WATER-FINE filter is a highly asymmetric membrane filter designed for filtration of aqueous fluids, including ink jet inks. The patented polysulfone membrane features a tapered pore structure for high flow rates and long on-stream life. The WATER-FINE filter is an excellent choice where fine filtration to 0.2μm is required, but with the economy of an industrial filter cartridge. This filter is ideal for final filtration of most office printing ink jet inks and will help assure printer performance.

Reference Pall literature publication 1254-B "Filtration Solutions for Ink Jet Ink Formulation" for specific recommendations.

Features

- Pall WATER-FINE filters are pleated polysulfone membrane filters with polypropylene hardware.

- Four nominal filter lengths are available:

- 254 mm/10 in.

- 508 mm/20 in.

- 762 mm/30 in.

- 1016 mm/40 in.

- Pall WATER-FINE filters for aqueous ink filtration are available in removal ratings of 0.1 μm, 0.2 μm and 0.45 μm absolute (complimentary grades are available for other applications).

| Features | Advantages | Benefits |

|

|

|

Specifications

Materials of Construction

| Filter Media | Highly Asymmetric Polysulfone Membrane |

| Core, Cage and Endcaps | Polypropylene |

| Gaskets/O-Rings | Ethylene Propylene (EPDM)1 |

1 Please contact Pall for other available materials

Operating Conditions2

Maximum operating differential pressures and temperatures| Operating Temperature | Maximum Differential Pressure |

| 68 °F/20 °C | 80 psid/5.5 bard |

| 203 °F/95 °C | 20 psid/1.4 bard |

2 Fluids that do not soften, swell or adversely affect the filter or materials of construction

Performance

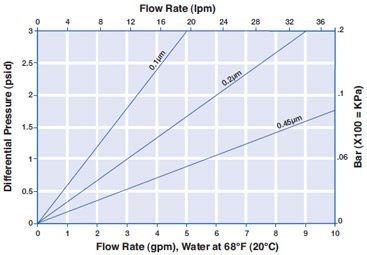

Typical Liquid Flow Rate versus Differential Pressure3

3 For liquids with viscosities differing from water, multiply the pressure drop by the viscosity in centipoise (cP)

Type

Filter Cartridges

Additional Information

Typical Media Structure Cross Section Photomicrograph

Ordering Information

This is a guide to part number structure only. For availability of specific options, please consult Pall

W F N [1] [2] [3] [4] [5] [6]

W F N [1] [2] [3] [4] [5] [6]

Table 1

| Code | Absolute Removal Rating4 |

| 0.1 | 0.1 μm |

| 0.2 | 0.2 μm |

| 0.45 | 0.45 μm |

4 Based on >99.9% Retention Rating by Standard Latex Bead Challenge

Table 2

| Code | Cartridge Length |

| 10 | 10 in. |

| 20 | 20 in. |

| 30 | 30 in. |

| 40 | 40 in. |

Table 3

| Code | Hardware |

| U | Polypropylene |

Table 4

| Code | Gasket/O-ring Material |

| E | EPDM (standard) |

| V | 'Viton' A |

| N | Buna N |

Table 5

| Code | End Configuration |

| No Code | Double-Open End (DOE) |

| M3 | SOE, flat closed end, external 222 o-rings |

| M7 | SOE, fin end, external 226 o-rings |

| M8 | SOE, fin end, external 222 o-rings |

Table 6

| Code | Special Ink Jet Specification |

| 147 | Preflushed cartridge and Ink Jet optimized media |

Reviews

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.