UltiKleen™ G2 STP Filter and KC Assemblies

The Pall UltiKleen STP filter is specifically engineered for filtering organic stripper. In the organic stripping process, a variety of sizes and types of gels and particles are generated as a result of the various ashing processes. The ashing can change the gels to a distribution of fine particles. These fine particles can quickly clog conventional design high surface area membrane filters.

The UltiKleen STP filter is the latest advance in Pall Corporation’s stripper filtration offerings. It uses a combination of carefully controlled submicron filter media. The filter is further optimized with gel-capturing, depth matrix media to effectively filter organic stripper. The proprietary media layering construction maintains high flows while removing unwanted particles and gels.

- Excellent gel retention

- High flow rates

- Low extractables (< 25 ppb in a 5% HCl extraction of 1.5 L for 24 hours)

- Downstream vent option with G2 KC assembly

- Multilayer filter media design

- All fluoro-polymer construction

- 100% integrity tested

- Long service life

Materials of Construction

| Components | Materials |

| Filter Medium | PTFE |

| Media Support | PFA |

| Inner Core / Outer Cage | PFA |

| End Caps | PFA |

| O-ring (for cartridge) | FEP Encapsulated fluoroelastomer |

| Housing (for KC type) | PFA |

Removal Ratings and Operating Conditions

| Removal Ratings | 0.05 μm, 0.1 μm, 0.2 μm | |

| Configurations | Cartridge | 254 mm / 10 inch |

| KC (Kleen-Change®) | T flow, In-line | |

| Nominal Filter Area | 10 inch | 1.7 m2 / 18.3 ft2 |

| Maximum Operating Temperature | 170 °C / 338 °F | |

| Maximum Forward Differential Pressure (Cartridge) | 0.6 MPaG @ 50 °C / 87 psig @ 122 °F | |

| Maximum Operating Pressure(KC Assemblies) | 0.49 MPaG < 25 °C / 71 psig < 77 °F 0.39 MPaG < 60 °C / 57 psig < 140 °F 0.34 MPaG < 90 °C / 49 psig < 194 °F 0.20 MPaG < 120 °C / 29 psig < 248 °F 0.15 MPaG < 150 °C / 22 psig < 302 °F 0.12 MPaG < 170 °C / 17 psig < 338 °F |

|

UltiKleenTM G2 STP Filter

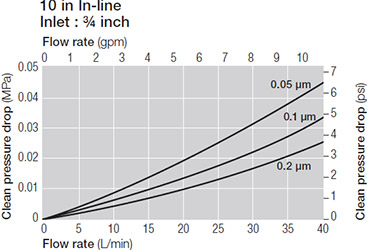

Pressure Drop vs. Liquid flow Rate (Water, 20 °C)1

UltiKleen ABFG1 Filter

UltiKleenTM G2 STP KC Assemblies

Pressure Drop vs. Liquid flow Rate (Water, 20 °C)1

*1Typical flow rates.

For liquids other than water, multiply the differential pressure by fluid viscosity in centipoise. Unit conversion: 1 bar = 0.1 MPa

Dimensions1

UltiKleenTM G2 STP Filter

Dimensions by Configuration

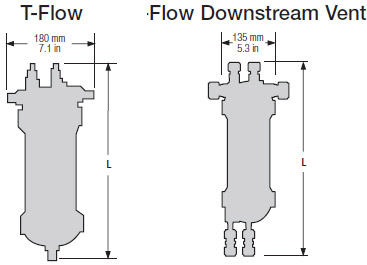

UltiKleenTM G2 STP KC Assemblies

G2 Kleen-Change® Assembly (LDFG/LDFV)

| In-Line | Nominal Length (L) (mm / in) |

T-flow | Nominal Length (L) (mm / in) |

| 12E2 | 396.5 / 15.6 | 12E2 | 408/ 16.1 |

| 12E51 | 412 / 16.2 | 12E71 | 403 / 15.9 |

| 124E51 | 412 / 16.2 | 13E0 | 495 / 19.5 |

| 16E8 | 428 / 16.9 | 13E1 | 432 / 17 |

| 16E51 | 436 / 17.2 | 13E2 | 442 / 17.4 |

| 17E0 | 448 / 17.6 | 13E6 | 416 / 16.4 |

| 17E1 | 445 / 17.7 | 13E9 | 433 / 17.1 |

| 17E51 | 442 / 17.4 | 13E51 | 473 / 18.6 |

| 17E71 | 462 / 18.2 | 13E71 | 444 / 17.5 |

| VT-style | Nominal Length (L) (mm / in) |

L-flow | Nominal Length (L) (mm / in) |

| 12E2 | 377 / 14.8 | 12E2 | 408/ 16.1 |

| 128E2 | 385 / 15.2 | VL-style | Nominal Length (L) (mm / in) |

| 12E71 | 377 / 14.8 | ||

| 12E72 | 377 / 14.8 | 2E2 | 440 / 17.35 |

| 128E71 | 402 / 15.8 | ||

| 128E72 | 402 / 15.8 | ||

| 13E1 | 445 / 17.5 | ||

| 13E51 | 444 / 17.4 | ||

| 168E71 | 403 / 15.9 | ||

| 168E72 | 403 / 15.9 | ||

*1Nominal length (mm / in)

UltiKleenTM G2 STP Filter

ABFG [1] STQ [2] 3E [3] [4]

Table 1

| Nominal Length | ||

| Code | Inch | L (mm) |

| 1 | 10 | 225 |

Table 2

| Code | Removal Ratings |

| D | 0.05 μm |

| T | 0.1 μm |

| R | 0.2 μm |

Table 3

| Code | O-ring options |

| H1 | FEP encapsulated fluoroelastomer |

| H38 | Perfrez*2 PXC-Ultra |

Table 4

| Code | Prewet Option |

| -K3 | Prewet filter (packaged in DI water) |

| -K7 | Prewet filter (packaged in DI water), Low metal extractables*3 |

UltiKleenTM G2 STP KC Assemblies

LDF [1] [2] 1STQ [3] [4] E [5] [6]

Table 1

| Code | Downstream Venting |

| G | N/A |

| V | Available |

Table 2

| Code | Flow |

| T | T-flow |

| N | In-line |

| L | L-flow |

Table 4

| Vent/Drain | ||||

| Code | Inlet/Outlet | Head end | Bowl end | Memo |

| 12 | 3⁄4 in male | 1⁄2 in male | 1⁄2 in male | T-flow / L-flow |

| 12 | 3⁄4 in male | 1⁄2 in male | 1⁄2 in female | Downstream venting-type |

| 12 | 3⁄4 in male | 3⁄8 in male | 3⁄8 in male | In-line |

| 124 | 3⁄4 in male | 1⁄4 in male | 1⁄4 in male | In-line |

| 128 | 3⁄4 in male | 1⁄2 in male | 1⁄2 in male | Downstream venting-type |

| 13 | 3⁄4 in male | 1⁄2 in female | 1⁄2 in female | T-flow |

| 16 | 1 in male | 1⁄2 in male | 1⁄2 in male | T-flow |

| 16 | 1 in male | 1⁄2 in male | 1⁄2 in female | Downstream venting-type |

| 16 | 1 in male | 3⁄8 in male | 3⁄8 in male | In-line |

| 164 | 1 in male | 1⁄4 in male | 1⁄4 in male | In-line |

| 168 | 1 in male | 1⁄2 in male | 1⁄2 in male | Downstream venting-type |

| 17 | 1 in female | 1⁄2 in female | 1⁄2 in female | In-line |

Table 5

| Code | Connections |

| 0 | Non-connection |

| 1 | 20 series (Flowell) |

| 2 | Super Pillar Type (Nippon Pillar)*4 |

| 51 | Flare style |

| 6 | FinalLock*5 |

| 71 | Super Pillar 300 P series (Nippon Pillar) |

| 72 | Super Pillar 300 P series L type (Nippon Pillar) |

| 8 | 60 series (Flowell) |

| 9 | 11CR series (Flowell) |

Table 6

| Code | Prewet Option |

| -K3 | Prewet filter (packaged in DI water) |

| -K7 | Prewet filter (packaged in DI water), Low metal extractables*6 |

*2 Perfrez PXC-Ultra is a trade mark of Applied Seals North Americas

*3 Please contact Pall on the extractable conditions

*4 Pillar is a trademark of Nippon Pillar Packing Co.

*5 FinalLock is a trademark of Kurabo Industries Ltd.

*6 Please contact Pall on the extractable conditions.

*7 Part numbers in combination with all codes are not always availbale.

Please contact Pall for the part number availability.

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.