Pall's P Emflon® HV2 filter is recommended specifically for high-viscosity fluids up to 15,000 mPa•s, such as polyimide coatings and adhesive emulsions.

The P Emflon HV2 is designed to withstand the high differential pressure associated with viscous fluids while maintaining stable flow rates.

Low extractables are ensured by the use of high density polyethylene hardware and PTFE medium.

The P Emflon HV2 is designed to withstand the high differential pressure associated with viscous fluids while maintaining stable flow rates.

Low extractables are ensured by the use of high density polyethylene hardware and PTFE medium.

| Features | Benefits |

| Optimized design for high-viscosity fluids |

|

| Ultipleat® construction |

|

| PTFE and HDPE materials |

|

Materials of Construction

| Medium | PTFE |

| Support and drainage | High-density polyethylene (HDPE) |

| Core | High-density polyethylene (HDPE) |

| Cage | High-density polyethylene (HDPE) |

| End caps | High-density polyethylene (HDPE) |

| O-ring | FEP Encapsulated fluoroelastomer |

| Removal Ratings | 0.2 μm, 0.45 μm, 1 μm |

| Filter Areas | 0.8 m2 / 8.6 ft2 |

| Maximum Temperature | 60 °C / 140 °F |

| Maximum Differential Pressure | 0.34 MPa / 3.5 kgf/cm2 (@ 40 °C / 104 °F) |

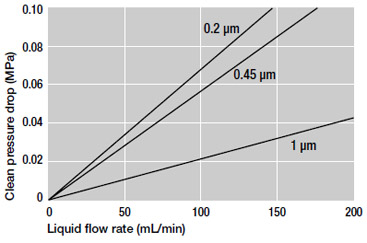

Pressure Drop vs. Liquid Flow Rate

3500 mPa•s Fluid

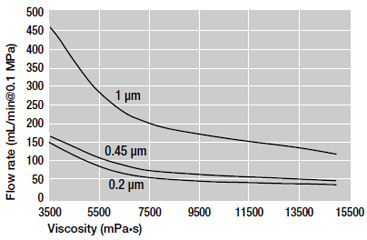

Flow rate vs. Viscosity

Filter Cartridges

This information is a guide to the part number structure and possible options. For availability of specific options and housing details, please contact Pall.

Example Part Number: ABD 2 UFR 7 E H1 -HV2 ( See bold references in tables below)

Part Number: ABD [1] [2] [3] E [4] -HV2

For availability of specific options and housing details, please contact your Pall Corporation representative.

Example Part Number: ABD 2 UFR 7 E H1 -HV2 ( See bold references in tables below)

Part Number: ABD [1] [2] [3] E [4] -HV2

Table 1 - Length (mm / in.)

| Code | Length (mm / in.) |

| 1 | 254 / 10 |

| 2 | 508 / 20 |

| 3 | 762 / 30 |

Table 2 - Removal Ratings (μm)

| Code | Removal Ratings (μm) |

| UFR | 0.2 |

| UFX | 0.45 |

| UFN | 1 |

Table 3 - O-ring size / Endcap

| Code | O-ring size / Endcap |

| 3 | AS568A-222 / Flat |

| 7 | AS568A-226 / Bomb fin |

| 8 | AS568A-222 / Bomb fin |

Table 4 - O-ring Material

| Code | O-ring Material |

| H1 | FEP Encapsulated fluoroelastomer |

For availability of specific options and housing details, please contact your Pall Corporation representative.

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.