The PhotoKleen™ EZD-3X filter is designed for small-volume dispense systems, which have the smallest footprint. The PhotoKleen™ EZD-3X filter has almost double the filter area (compared to the PhotoKleen™ EZD-3 filter) in the same capsule size. This allows for lower pressure drop during filtration or allows the installation of finer filtration at the same pressure drop. Two filter media types are available, Asymmetric Nylon 6,6 and HDPE. The naturally hydrophilic Nylon 6,6 membrane allows for spontaneous wettability, and its polarity has been shown to lower defectivity on the patterned wafers. The XP option is available for advanced lithography processes.

PhotoKleen™ EZD-3X filters are designed to fit into all PhotoKleen™ EZD-3 head manifolds

Features and Benefits

- Double the filter area in the same size capsule (Ref. PhotoKleen™ EZD-3 filter)

- Easy change out style filter assembly

- Two membrane material types available

- Minimized hold-up volume, and top in / top out flow direction with side conduit for laminar filling

- Offers lower pressure drop for higher viscosity fluids

- Reduces tool down time by extending filter change outs

- Optimized media selection for target applications

- Minimized organic extractables by XP treatment for rapid start-up and reducing chemical wastes.

- XP option guarantees low organic, metal and particle cleanliness for the most advanced processes.

PhotoKleen™ EZD-3X filters are designed to fit into all PhotoKleen™ EZD-3 head manifolds

Materials of Construction

| Components | Materials |

| Filter Media |

|

| Support and Drainage | |

| Core, Cage, and End Caps | |

| Housing | |

| O-ring | Perfluoroelastomer |

| Removal Ratings |

|

| Filter area |

|

| Maximum Forward Differential Pressure | P-Nylon : 0.27 MPa @ 20 °C / 39 psid @ 60 °F PE-Kleen : 0.29 MPa @ 30 °C / 42 psid @ 86 °F |

| Maximum Operating Temperature | 30 °C / 86 °F |

| Maximum Operating Pressure | 0.29 MPaG @ 30 °C / 42 psig @ 86 °F |

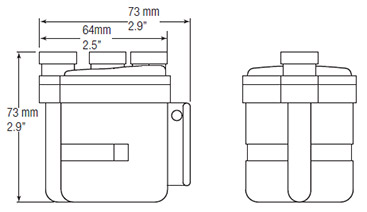

Dimensions2

*2 PhotoKleen™ EZD-3 head manifolds are compatible with PhotoKleen™ EZD-3X capsules.

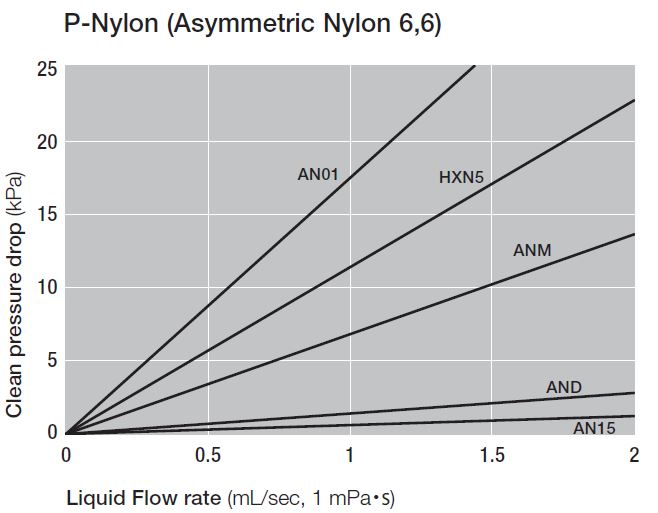

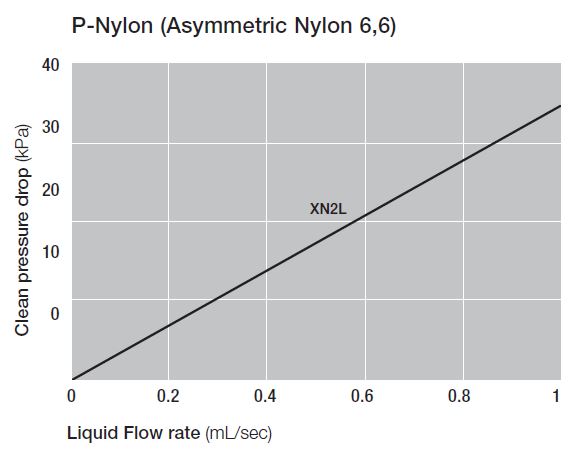

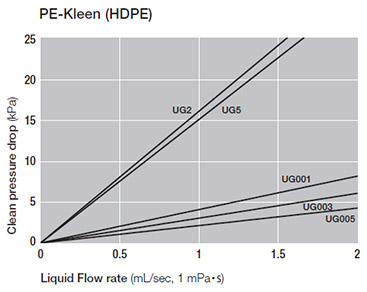

Typical Flow Characteristics - 1cP fluid, 20℃

Filter Capsules

Part Numbers / Ordering Information3

PHD12 [1] EH11B

Table 1

| Code | Filter Media | Removal ratings | |

| XN2L4 | P-Nylon | Asymmetric Nylon6,6 | 2 nm |

| HXN54 | Asymmetric Nylon6,6 | 5 nm | |

| AN01 | Asymmetric Nylon6,6 | 10 nm | |

| ANM | Asymmetric Nylon6,6 | 20 nm | |

| AND | Asymmetric Nylon6,6 | 40 nm | |

| AN15 | Asymmetric Nylon6,6 | 0.15 μm | |

| UG2 | PE-Kleen | HDPE | 2 nm |

| UG5 | HDPE | 5 nm | |

| UG001 | HDPE | 10 nm | |

| UG003 | HDPE | 30 nm | |

| UG005 | HDPE | 50 nm | |

*3 For XP option add –XP to end of part number for 10nm / 20nm removal ratings.

*4 XP treatment is standard on 2nm / 5nm removal rating.

Caution: For optimal filtration performance, it is recommended to replace your filters at-least once a year. Annual replacements will reduce the potential of any leakages that may result due to prolonged chemical exposure. Pall warrants its filters for a period of 1 year from the date of shipment.

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.