The PhotoKleen flter assembly is a compact capsule assembly designed for clean, simple and safe filter changeout. It is well suited for applications that demand higher purity – such as developer, solvents and photoresist filtration – because it eliminates all polypropylene components. Use of the assembly in systems can improve overall performance. The XP option is available for advanced lithography processes.

Features

- Low hold-up volume

- Vent at highest location

- Drain a lowest location

- Low Pressure drop

- Manufactured in a cleanroom environment

- O-ring less design

- Minimized organic extractables by XP option

- XP option guarantees low organic, metal and particle cleanliness for the most advanced processes.

Benefits

- Faster start-up

- Minimize chemical waste

Materials of Construction

| Components | Materials |

| Filter Medium | PE-Kleen P-Nylon |

| Support and Drainage | HDPE ( |

| Shell, Core, Cage and End Caps | HDPE ( |

| PE-Kleen filter | P-Nylon filter | ||||||||||

| Grade | UG2 | UG5 | UG001 | UG003 | XN2L | HXN5 | AN01 | ANM | AND | AN151 | |

| Removal Ratings | 2 nm | 5 nm | 10 nm | 30 nm | 2 nm | 5 nm | 10 nm | 20 nm | 40 nm | 0.15 μm | |

| Filter areas (cm2) | DDF1 | 2,600 | 2,500 | 2,500 | 2,200 | 2,900 | 1,900 | 2,500 | 2,500 | 2,500 | 2,500 |

| DDF2 | 5,200 | 5,200 | 5,100 | 4,400 | 5,900 | 4,100 | 5,300 | 5,300 | 5,300 | - | |

| Maximum Operating Temperature | 30 ˚C / 86 ˚F | ||||||||||

| Maximum Operating Pressure | 290 kPaG @ 30 ˚C / 42 psi @ 86 ˚F | ||||||||||

| Maximum Forward Differential Pressure | 290 kPa @ 30 ˚C / 42 psid @ 86 ˚F | ||||||||||

1 Available for DDF1 configuration only.

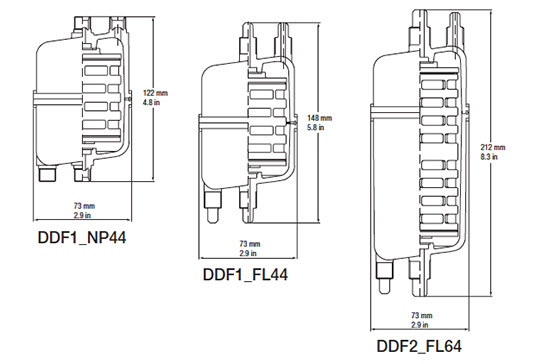

Dimensions

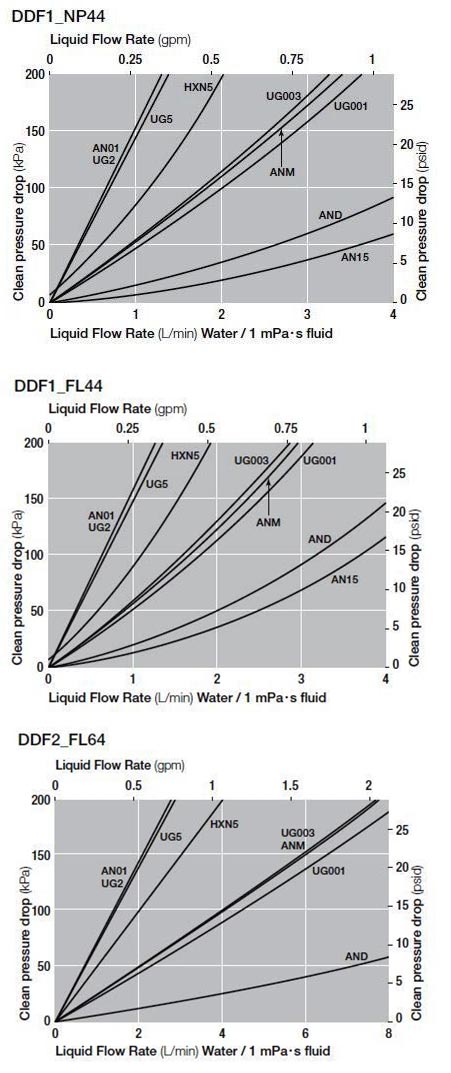

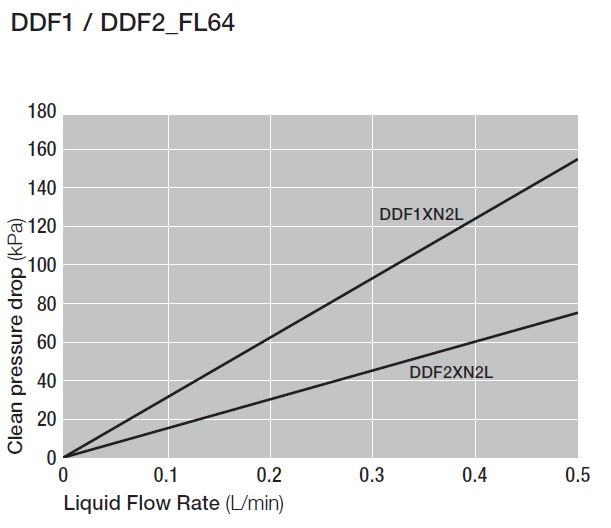

Typical Flow Characteristics - 1cP fluid (20℃)

Part Numbers / Ordering Information2, 3

DDF [1] [2] E [3]Table 1

| Code | Scale |

| 1 | Small volume |

| 2 | Middle volume |

Table 2

| Code | Medium | Removal Ratings |

| UG2 | HDPE | 2 nm |

| UG5 | HDPE | 5 nm |

| UG001 | HDPE | 10 nm |

| UG003 | HDPE | 30 nm |

| XN2L | Nylon 6,6 | 2 nm |

| HXN5 | Nylon 6,6 | 5 nm |

| AN01 | Nylon 6,6 | 10 nm |

| ANM | Nylon 6,6 | 20 nm |

| AND | Nylon 6,6 | 40 nm |

| AN15 | Nylon 6,6 | 0.15 μm |

Table 3

| Code | Connections Inlet, Outlet / Vent, Drain |

| NP44 | 1⁄4 in. Pillar fitting4 / 1⁄4 in. Pillar fitting |

| FL44 | 1⁄4 in. flare style / 1⁄4 in. flare style |

| FL64 | 3⁄8 in. flare style / 1⁄4 in. flare style |

2 Filter elements may not be available in all configurations. Contact your local Pall representative for availability.

3 For XP option, add –XP to the end of a part number for 10nm / 20nm removal ratings.

(XP treatment is standard for 2nm / 5nm products)

4 Pillar fitting is a trademark of Nippon Pillar Packing Co., Ltd.

Caution: For optimal filtration performance, it is recommended to replace your filters at-least once a year. Annual replacements will reduce the potential of any leakages that may result due to prolonged chemical exposure. Pall warrants its filters for a period of 1 year from the date of shipment.Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.