The Mini Ultramet-L®1100 Series filter assembly is available with an all 316L stainless steel housing and either a 316L stainless steel or nickel filter. It is designed for ≥ 1.5 nm (0.0015 μm) filtration of semiconductor grade gases, and is ideally suited for point-of-use applications. The 1100 Series filter is recommended for all applications with process gases that are compatible with 316L stainless steel or nickel.

- One circumferential weld in entire product

- State-of-the-art 316L stainless steel or nickel medium

- Excellent particle removal efficiency vs. pressure drop

- Accommodates extremely high flow rates for the assembly size

- Excellent gas displacement and desorption characteristics

- High temperature and pressure capabilities

- Compact size

- 100% helium leak tested

- Cleanroom manufactured and packaged

Materials

- Electropolished 316L stainless steel housing

- Housing material meets or exceeds VIM/VAR specifications

- EU Pressure Equipment Directive: Assemblies have been evaluated and designed using SEP per the European Union’s Pressure Equipment Directive 2014/68/EU and are not CE marked.

- ≤ 0.13 μm / 5 μin Ra internal surface finish

- Cr:Fe (1:1) chromium-enriched internal housing surface chemistry

- 316L stainless steel or nickel filter medium

Removal Rating

- ≥ 1.5 nm

Preconditioned Options

1102 Series

- < 10 ppb moisture contribution (Qualified per SEMASPEC test method #90120397B-STD.)

- < 10 ppb THC contribution (Qualified per SEMASPEC test method #90120396B-STD.)

- < 10 ppb O2 contribution (Qualified per SEMASPEC test method #90120398B-STD.)

- No particle contribution above background ≤ 1 particle / m3 or ft3

Connections

- 1⁄4 in. gasket seal (VCR1 or compatible)

- 1⁄4 in. butt weld (0.89 mm / 0.035 in. wall)

Operating Conditions

- Maximum operating pressure:

- 20.7 MPa @ 38 °C / 3,000 psig @ 100 °F

- 11.6 MPa @ 450 °C / 1,685 psig @ 840 °F

- Maximum allowable differential pressure:

316L stainless steel filter:- 0.86 MPa @ 38 °C / 125 psid @ 100 °F

- 0.41 MPa @ 450 °C / 60 psid @ 840 °F

- 0.69 MPa @ 38 °C / 100 psid @ 100 °F

- 0.41 MPa @ 450 °C / 60 psid @ 840 °F

Particle Removal Characteristics

- 109 particle reduction up to 15 slpm

Leak Rating

- 100% helium leak tested to 10-9 atm•cm3/s

- Design validated to 10-11 atm•cm3/s

1VCR is a trademark of Swagelok Company.

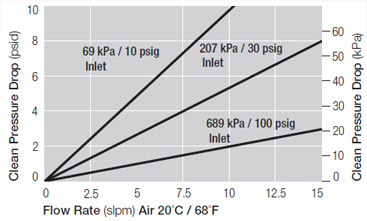

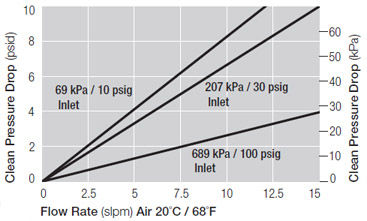

Pressure Drop vs. Gas Flow Rate

316L Stainless Steel Filter Assembly

Nickel Filter Assembly

Assemblies

Filtration

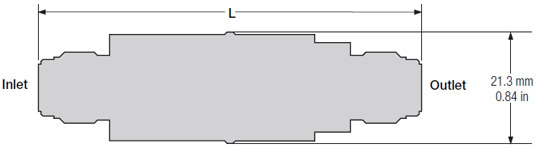

Dimensions

| Part Number | Description | Fitting Type | Preconditioned | |

| GLFF1100VMM4 | All 316L stainless steel | 1⁄4 in. gasket seal (VCR or compatible) male / male | 84 / 3.31 | No |

| GLFF1100VFM4 | All 316L stainless steel | 1⁄4 in. gasket seal (VCR or compatible) female inlet / male outlet | 88 / 3.47 | No |

| GLFF1100BW4 | All 316L stainless steel | 1⁄4 in. butt weld, 0.89 mm / 0.035 in wall | 42.5 / 1.75 | No |

| GLFF1102VMM4 | All 316L stainless steel | 1⁄4 in. gasket seal (VCR or compatible) male / male | 84 / 3.31 | Yes |

| GLFN1100VMM4 | Nickel media, 316L stainless steel housing | 1⁄4 in. gasket seal (VCR or compatible) male / male | 84 / 3.31 | No |

| GLFN1100VMF4 | Nickel media, 316L stainless steel housing | 1⁄4 in. gasket seal (VCR or compatible) male inlet / female outlet | 71.1 / 2.80 | No |

| GLFN1100BW4 | Nickel media, 316L stainless steel housing | 1⁄4 in. butt weld, 0.89 mm / 0.035 in. wall | 42.5 / 1.75 | No |

| GLFN1102VMM4 | Nickel media, 316L stainless steel housing | 1⁄4 in. gasket seal (VCR or compatible) male / male | 84 / 3.31 | Yes |

Unit conversion: 100 kilopascals = 1 bar

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.