The PSP Sealed-In-Line Series filter assemblies are specifically designed for filtration of gas processes with high flow rates.

- All stainless steel construction

- High particle retention

- Very high flow rates with low differential pressure

- High temperature and pressure capabilities

- Excellent gas displacement and desorption characteristics

- 100% integrity tested

- Clean room manufactured and packaged

| Materials |

|

| Removal Rating1 |

|

| Connections |

|

| Configurations |

|

| Preconditioning |

|

| Operating Conditions |

|

| Certifications |

|

| Leak Rating |

|

1Particle rating based on laboratory testing with NaCl aerosol.

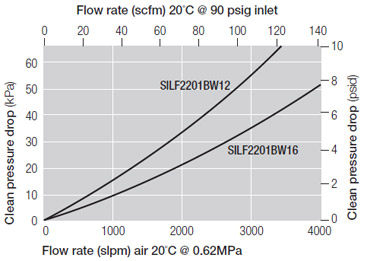

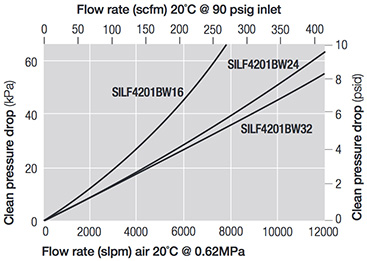

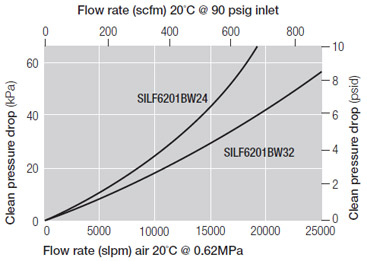

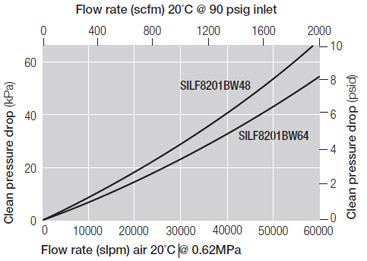

Pressure Drop vs. Gas Flow Rate

SILF2

SILF4

SILF6

SILF8

Assemblies

Filtration

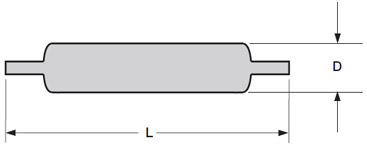

Dimensions

Part Numbers / Ordering Information

| Part Number | Description | Nominal Diameter (D) (mm/in.) | Nominal Length (L) (mm/in.) |

| SILF2201BW12 | 22 in. tube, 3⁄4 in. buttweld | 64 / 2.5 | 781 / 30.8 |

| SILF2201BW16 | 22 in. tube, 1 in. buttweld | 64 / 2.5 | 781 / 30.8 |

| SILF4201BW16 | 22 in. tube, 1 in. buttweld | 102 / 4.0 | 826 / 32.5 |

| SILF4201BW24 | 22 in. tube, 1 1⁄2 in. buttweld | 102 / 4.0 | 826 / 32.5 |

| SILF4201BW32 | 22 in. tube, 2 in. buttweld | 102 / 4.0 | 826 / 32.5 |

| SILF6201BW24 | 22 in. tube, 1 1⁄2 in. buttweld | 168 / 6.6 | 864 / 34.0 |

| SILF6201BW32 | 22 in. tube, 2 in. buttweld | 168 / 6.6 | 864 / 34.0 |

| SILF8201BW48 | 22 in. tube, 3 in. buttweld | 219 / 8.6 | 864 / 34.0 |

| SILF8201BW64 | 22 in. tube, 4 in. buttweld | 219 / 8.6 | 864 / 34.0 |

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.