The Answer to Gas Filtration Applications

Clean, aerosol free gas is critical to equipment reliability and optimized operations in the refinery and chemical industries. Pall's SepraSol™ liquid/gas coalescers provide high-efficiency liquid and solid removal from contaminated gases reducing maintenance and operating costs. A patented chemical surface treatment enhances the coalescer drainage properties leading to improved performance allowing for smaller systems, lower pressure drop, and improved ability to recover from liquid slugs. Pall's high-efficiency SepraSol coalescer is recommended for a wide range of gas filtration applications, including:

- Protecting compressors and turbines

- Protecting low and ultra-low NOx burners by cleaning fuel gas

- Removing lubrication oil, water, compressor wear products, corrosion products, and other solids from effluent gas streams

- Minimizing foaming tendencies in sweetening and dehydration units

- Minimizing amine and glycol losses downstream of gas sweetening and dehydration units

- Cleaning dirty fuel gas and instrument gas

- Controlling injection well plugging during gas flooding

- Protecting catalysts, desiccants and absorbants

- Removing lube oil from ammonia gas

Coalescer Technical Information

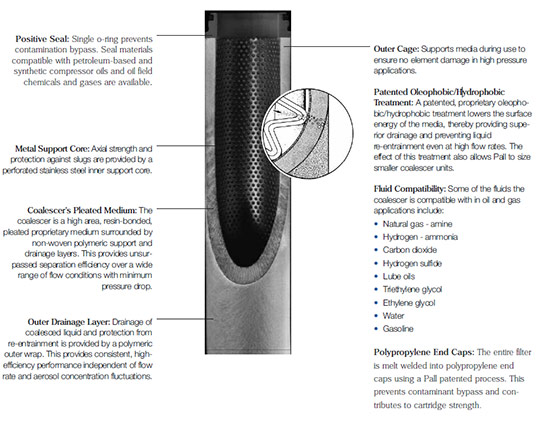

Oleophobic/Hydrophobic Treatment– All of Pall's SepraSol liquid/gas coalescers receive a patented oleophobic/hydrophobic treatment. Chemically treating the coalescer lowers the surface energy of the medium and promotes rapid drainage of the coalesced liquids. Benefits of the surface treatment include increased capacity for liquid challenges, smaller overall assembly sizes, lower pressure drop, and improved ability to recover from liquid slugs.Features, Advantages and Benefits of the Pall SepraSol Liquid/Gas Coalescer

Pall’s SepraSol liquid/gas coalescers eliminate virtually all solids and liquids in a gas stream. Downstream liquid levels are as low as 0.003 ppmw1 and the solids removal rating is 0.3 micron (μm) (99.99% efficiency).2| Features | Advantages | Benefits |

| Patented Oleophobic/ Hydrophobic Media Treatment |

|

|

| High Effective Filtration Area |

|

Lower operating and maintenance costs |

| High-efficiency Media and Draining Materials |

|

Lower maintenance costs and improved availability |

1 Test conditions used to measure efficiency area as follows:

Flow rate: 900 SCF/minute per 30 in. element at 37.8°C (100°F) and 6.9 bar (100 psig)

Liquid inlet: 50 ppmw oil

2 Per sodium chloride test

Additional Features of the Pall SepraSol Liquid/Gas Coalescing Filter

Pall coalescing filter cartridges operate economically with high separation efficiency and long life.

Performance Specification

| Solid Removal Rating | 0.3 μm (99.99%) |

| Temperature Rating | 180 °F (82 °C) 150 °F (65 °C) with Water |

| Clean & Saturated Pressure Drop | Sized to your specification |

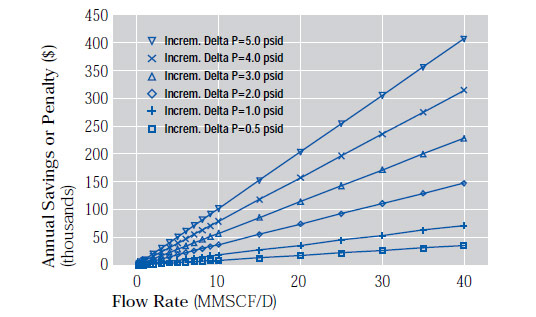

Figure 1: Effect of Pressure Drop on Compressor Operating Costs5

5 Conditions: Delta P on inlet pressure

Inlet Pressure = 20 psia

Outlet Pressure = 200 psia

Gas compressed is methane

Costs based on $0.07/kwhr

Pall Corporation applies a patented oleophobic/hydrophobic chemical treatment on all of its SepraSol liquid/gas coalescers. This allows the coalescers to operate at a lower saturated pressure drop. As shown on Figure 1, a small difference in saturated pressure drop can result in significant savings in operating costs.

About Coalescer Efficiency Ratings

The measurement of the efficiency and the pressure drop of a coalescer should reflect operating conditions. Many manufacturers of coalescers measure efficiency using the dioctyl phthalate (DOP) test. The DOP test was not originally designed to measure the performance of a coalescer under operating conditions seen in the oil and gas industry. Rather, the DOP test is performed under the following conditions:- Measures only capture efficiency and does not indicate how much liquid is at the filter outlet. It is the outlet concentration, which will indicate whether downstream equipment and processes are vulnerable to damage.

- Measures only the percent removal of DOP aerosols that are 0.3 μm compared to a range of sizes normally seen in oil and gas applications.

- Measures the removal of DOP, a liquid not typically found in oil and gas applications.

- Performed under a vacuum, not typical of operating conditions.

- Performed on a dry coalescing element; the effectiveness of a coalescer should be measured when a coalescer is completely saturated.

Pall LASE Test vs. Conventional DOP

| Pall LASE Test | DOP Test | LASE Advantage | |

| Efficiency Rating | Measures ppmw of total downstream aerosol concentration | Measures only the capture efficiency of 0.3 μm DOP aerosols | Specifies performance based on total liquid removal |

| Test Contaminant | Polydispersed 20 wt. compressor lube oil (size range 0.1-1.0 μm) | Monodispersed dioctyl phthalate (size range at 0.3 μm only) | Closely simulates actual process contamination |

| Downstream Contaminant Measurement | Full flow membrane sampling of all size contaminants | Indirect light scattering of 0.3 μm contaminants | Directly measures the amount of all liquid downstream |

| Pressure Conditions | Performed under positive pressure conditions | Performed under vacuum | More closely reflects actual process pressure conditions |

| Cartridge Condition | Performed on a saturated cartridge | Performed on dry cartridge | Reflects actual process cartridge service |

| Pressure Drop Measurement | Measures operating saturated cartridge pressure drop | Measures dry cartridge pressure drop | Provides a more realistic service pressure drop |

Coalescers

Nominal Cartridge Dimensions

| Part Number | Outer Diameter (mm/in.) | Length (mm/in.) | Surface Area (m2/ft2) |

| CC3LGA7H133 | 70/2.75 | 762/30 | 0.88/9.5 |

| CC3LGB7H134 | 70/2.75 | 762/30 | 0.88/9.5 |

3 CC3LGA can replace CC3LG7 in existing Pall coalescing housings.

4 Completely compatible with amines and ammonia.

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.