Ultipor® HT filters have a pleated, high area construction for long service life. The unique medium structure consists of a high temperature binder resin which coats the fine glass fibers. The filter’s materials of construction are qualified for uses up to 425°F (218°C) with compatible fluids. The double open ended filters are installed over a tie rod/seal nut assembly. The flow pattern is outside to inside.

Benefits

- Optimized pleat pack filtration helps to develop filter cake

- Batch to batch consistency

- Core collapse pressure rated to 75 psid (5.17 bard) @ 425°F (218°C)

- Available with retention ratings of 1, 10, 20, and 70 micron (μm)1

- Able to process tough oil fractions, containing fine suspended solids

- Large surface area provides long service life

Housing Information

ASME rated filter vessels are available in a variety of materials including carbon steel, stainless steel, and other alloys to meet service requirements. Vessels may also be custom built to comply with other regional and local codes and practices. Please contact your local representative to discuss fabrication specifications, instrumentation, piping/manifolding needs, and skid mounting.

Performance Specifications

Filter Grades (rated at 99% efficiency):2

1, 10, 20, 70 μm

Maximum Temperature:

425°F (218°C)

Maximum Forward Differential Pressure:3

40 psid (2.75 bard) @ 425°F (218°C)

Recommended Changeout Differential Pressure:

30 psid (2.0 bard) @ 425°F (218°C)

Product Specifications

Materials of Construction:4

| Filter Media: | Resin bonded glass fiber on aramid substrate |

| Drainage Mesh: | Steel |

| Support: | Glass |

| Gaskets: | Graphite Sheet, Fluorocarbon Elastomer |

| Adhesives: | Epoxy Resin |

| Core/End Caps: | Carbon Steel (zinc plated) |

Dimensions (nominal):

| Outside Flange Diameter: | 6.12 inch (15.54 cm) |

| Outside Filter Diameter: | 6 inch (15.24 cm) |

| Inside Filter Diameter: | 3.45 inch (8.76 cm) |

| Length: | 44 inch (111.76 cm) |

| 1 | For information to order these grades, consult your local Pall representative. |

| 2 | The test procedure used is an adaptation of ISO 16889, modified to determine the micron size above which particles are quantitatively removed. |

| 3 | Normal flow direction is outside-to-inside. Reverse flow operation is not recommended. |

| 4 | Ultipor HT elements are manufactured by Pall to exacting procedures and strict quality controls. |

Ultipor HT filters are designed for a variety of applications. These high temperature filters are frequently used to process tough oil fractions, containing fine suspended solids typically found in processes related to desulphurization and fuels upgrading. These fluids, left untreated, can reduce reactor runtime and foul critical process equipment. Other applications include:

- Heated tank farm fluids

- Reactor bed feed filtration (e.g. Hydrotreaters)

- Heat exchanger protection

- Gas to liquid wax products

- Lubricant processing

- Hydrogenation product polishing

- Hot motor fuel product blending

Liquid Retention Ratings (μm) (ISO 16889 modified)

| Cartridge Designation | 99%Efficiency (Beta 100) |

| GK010 | 1 |

| GK100 | 10 |

| GK200 | 20 |

| GK700 | 70 |

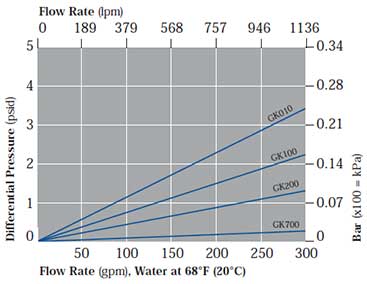

Typical Flow vs. Differential Pressure for Application Sizing

Part Numbers/Ordering Information

HT0644 ■ ♦ (e.g., HT0644GK200G)

| Code ■ | Filter Grades (micron) |

| GK010 | 1 |

| GK100 | 10 |

| GK200 | 20 |

| GK700 | 70 |

| Code ♦ | Gasket Materials |

| G | Graphite Sheet |

| H | Fluorocarbon Elastomer |

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.