Benefits

As part of continued component cleanliness 'pass off' checks or predictive maintenance programs the PCM400 monitor quickly reports test data so that ongoing assessments can be made.Early detection of abnormal fluid cleanliness allows for timely investigation and corrective actions to be implemented.

The PCM400 can be permanently installed to monitor critical applications (including component test facilities) or used as a portable device for routine condition monitoring of various fluid systems.

PCM400 Monitor Features

- Proven mesh blockage technology

- Results not affected by water or air

- Monitors dissolved water content (% saturation or PPM output for specific fluids (PCM400W only))

- High and low pressure on-line or off-line sampling

- Continuous monitoring

- 500 test memory

- ¼" BSP or test point hose connection

PC-based trending software included - Viscosity output in centistokes (cSt)

- Real time graphical representation

Operation

A detachable hand held touch screen programmer allows for simple menu driven input of sample identification, monitor configuration and data output in either ISO 4406, NAS 1638 or SAE AS 4059 formats.The hand held programmers display shows real time data and test results which are automatically stored for subsequent trending and evaluation.

| Power supply: | 90-230 VAC or integral 19 VDC battery |

| Temperature: | 10°C to 80°C (50°F to 176°F) |

| Compatibility: | Water glycols, aqueous solutions. Petroleum and synthetic oils (hydraulic lubricating, dielectric, etc.) fuels, industrial phosphate esters. |

| Seals: | Fluorocarbon |

| Operating viscosity: | 1.5 to 450 cSt (30 to 2,200sus) |

| Pressure: | 0 to 315 bar (4568 psi) max |

| Range: | ISO 4406: 9/7 to 21/17 NAS 1638: 1 to 10 @ 5-15 µm SAE AS 4059: >6 µm 1B to 10B >14 µm 1C to 10C |

| Accuracy: | ± 1/2 ISO code |

| Output: | RS232 |

| Enclosure: | IP 65 (NEMA 4) |

| Weight: | 10.8 kg (22 lb) |

| Dimensions: | 340 x 240 x 265 mm (14 x 10 x 10 inches) |

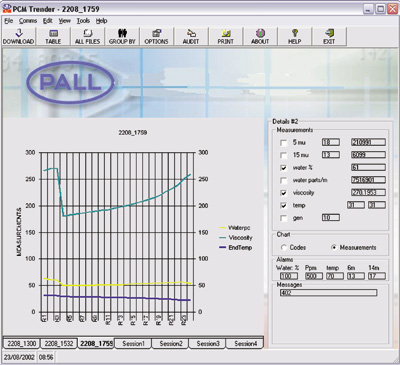

PCM Trender software features

- Graphical and spreadsheet reporting

- Trending capabilities

- Customer defined alarm limits

- Printable reports

- Component wash fluids

- Cutting fluids

- Aqueous solutions

- Coolants

- Water glycols

- Mineral and synthetic oils

- Lubricants

- Fuels

Table 1: Water Sensor

| Code | Description |

| None | No Water Sensor fitted |

| W | Water Sensor fitted |

Table 2: Fitting Type

| Code | Description |

| M | 1⁄4 in. BSPP Female Swivel fitting to metric test point |

| I | 1⁄4 in. BSPP Female Swivel fitting to imperial test point |

| U | 1⁄4 in. NPT fitting and end cap |

Table 3: Mains Lead

| Code | Description |

| A | UK Power Lead |

| B | European Power Lead |

| C | USA Power Lead |

| D | Australian Power Lead |

| E | Japanese Power Lead |

Table 4: Language

| Code | Description |

| DA | Danish |

| DE | German |

| EN | English |

| ES | Spanish |

| FR | French |

| IT | Italian |

| NL | Dutch |

| NO | Norweigian |

| SV | Swedish |

Printer Kit and Accessories

![]()

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.