Order Products

1/EA

1

1/EA

1

Effectively Separate Liquid/Liquid Dispersions Optimize Coalescer and/or Pre-fi lter Life

Pall’s PhaseSep EL coalescer provides chemical/ petrochemical, oil & gas, and refinery plants containing aggressive or high temperature streams with improved separation efficiency via a coarse coalescer format. This product performs well in applications with high solids and difficult oil/water emulsions. The PhaseSep EL coalescer differentiates from bulk separators and commodity coalescers by achieving low OPEX and lower CAPEX with high efficiency contaminant separation.

PhaseSep EL Coalescer vs. ‘Original’ PhaseSep Coalescer

The PhaseSep EL system is typically a multiple-stage system, starting with prefiltration to remove particulate matter, followed by either a one-stage horizontal coalescer or two-stage integrated vertical coalescer/ separator stack to separate the two liquid phases. PhaseSep EL coalescers will remove oil and grease to a level of 20 ppmw, or free water to a level as low as 15 ppmv, and be effective over a wide range of conditions such as inlet liquid contaminant concentration as high as 0.1% and interfacial tension less than 10 dynes/cm1 . The PhaseSep EL coalescer system is available in two different housing configurations. Both configurations begin with a filtration stage to remove solid contaminants.

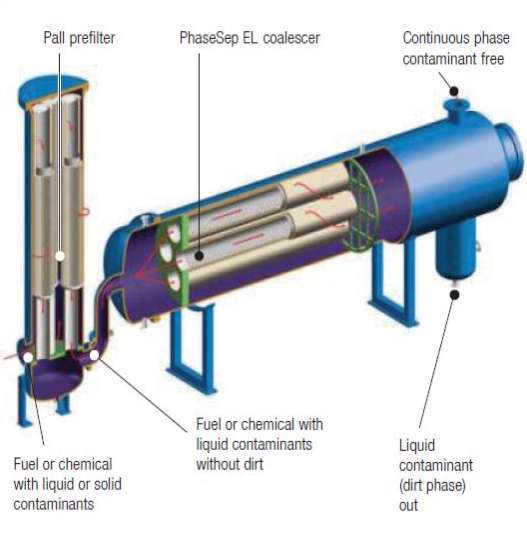

In a horizontal housing, the liquid/liquid mixture enters the coalescing element and flows inside-to-outside, small liquid dispersed phase droplets suspended in the continuous phase come together, or coalesce, as the mixture moves through the PhaseSep EL coalescer. The large coalesced droplets of the dispersed phase separated by gravity in the horizontal housing and are removed. The size of the housing is a function of the flow rate, IFT, viscosity, and specific gravity of the liquids.

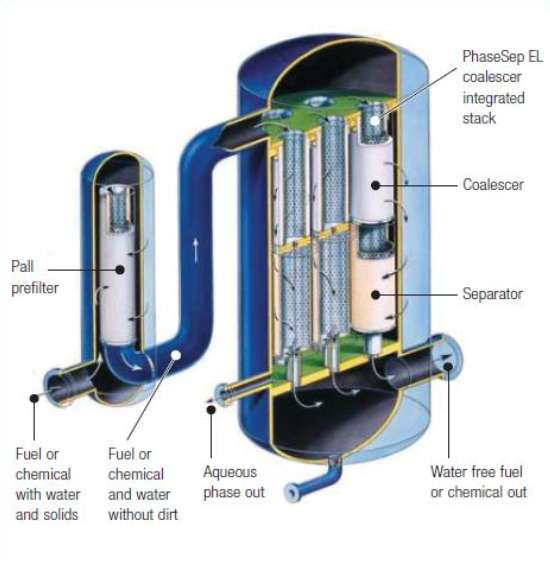

The liquid/liquid mixture enters the coalescing element and flows inside-to-outside. Small liquid droplets suspended in the continuous phase come together, or coalesce, as the mixture moves through the coalescer medium.

Contaminant-free liquid and large droplets of the dispersed phase flow toward the separator located directly below the coalescer stage. Flowing is outside-to inside. The separator medium is hydrophobic preventing the aqueous phase from entering the separator. Only the non-aqueous continuous phase fluid flows through the separator. The two liquids are removed by separate drain connections.

Contaminant-free liquid and large droplets of the dispersed phase flow toward the separator located directly below the coalescer stage. Flow through the separator is outside-to-inside. The separator medium is hydrophobic and prevents the aqueous phase from entering the separator. Only the non-aqueous continuous phase fluid flows through the separator. The two liquids are removed by separate drain connections.

Table 1: Coalescer Selection Guide

| Process Condition | Recommended Product |

|---|---|

| The dispersed phase fluid is aqueous and a horizontal vessel footprint is acceptable | PhaseSep EL coalescer in a horizontal housing without separator |

| The dispersed phase fluid is oil and the continuous phase fluid is aqueous | |

| The dispersed phase fluid is aqueous and minimal footprint is required | PhaseSep EL coalescer/ separator stack in a vertical housing |

Figure 1. PhaseSep EL Liquid/Liquid Separation System with Coalescer in a Horizontal Housing with Prefilter (for removal of aqueous from hydrocarbon)

Figure 2. PhaseSep EL Liquid/Liquid Separation System with an Integrated Coalescer/Separator Stack in a Vertical Housing with a Prefilter

Not all coalescers provide a high efficiency quantitative removal of dispersed liquid contaminants and can handle emulsions with low interfacial tensions (IFTs). For example, conventional cartridge and mesh pack coalescers made of glass fiber media begin to lose efficiency when the IFT of the emulsion gets below 20 dynes/cm. In contrast, the PhaseSep EL coalescer from Pall is constructed of a high-efficiency, engineered polymer medium, making it well suited for numerous aggressive service liquid/liquid separation applications with low IFTs.

| Features | Advantages | Benefits |

|---|---|---|

| High Performance, Coarse Grade engineered polymer medium |

|

|

|

|

|

|

|

|

| Non-disarming coalescing medium |

|

|

|

|

|

| Availability of a High-Performance Integrated Stack Design – Coalescer and Separator |

|

|

The PhaseSep EL coalescer is compatible with hydrocarbon fuels and fuel additives, alkanes, olefins, aromatics, ethylene glycol, trace amounts of IPA and methanol, water in the pH range of 1-14, alkanol amine – water solutions (MEA, DEA, MDEA, and fluids generally compatible with epoxy, fluorocarbon or 304 SS. For compatibility information with a specific chemical, please contact your Pall representative or distributor.

| Maximum operating temperature: | 149°C/300°F |

| Maximum differential pressure: | 3.5 bard/50 psid at 21°C/70°F |

| Oil in Water Performance1: | < 20 ppmw oil & grease per EPA1664 or ALPHA5520B |

| Water in Oil Performance1: | < 15 ppmv based on AquaGlo (free water) detection, up to 0.1% water |

| Recommended change-out: |

1.0 bard/15 psid at 21°C/70°F |

Begin reducing your capital and operating costs today. Contact your local Pall distributor or call Pall directly to arrange for a budgetary quotation and pilot test of the PhaseSep EL coalescer technology.

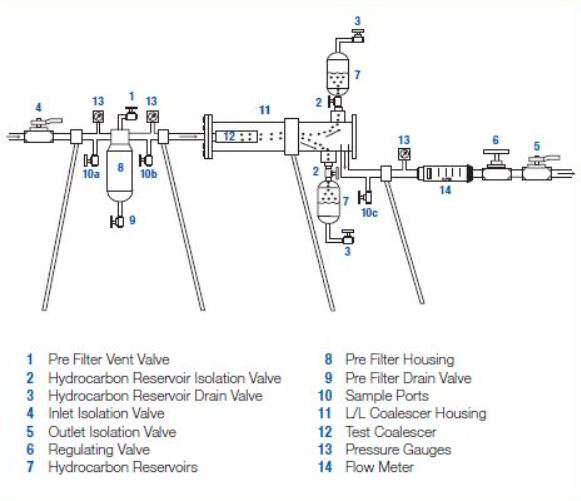

Figure 3. Illustration of Pall pilot scale liquid/liquid coalescer test stand.

Coalescers

| Part Number | Description | Outer Diameter (cm/in) nominal | Length (cm/in) nominal |

|---|---|---|---|

| LCS06ELPH | PhaseSep EL 6” Test Coalescer | 7/2.75 | 15.2/6 |

| LCS2ELPH | PhaseSep EL 20” Coalescer | 10.7/ 4.2 (flange) 9.53/3.75 (main element) | 50.8/20 |

| LCS4ELPH | PhaseSep EL 40” Coalescer | 10.7/ 4.2 (flange) 9.53/3.75 (main element) | 101.6/40 |

| LSS1F1H | Separator | 9.53/3.75 | 50.8/20 |