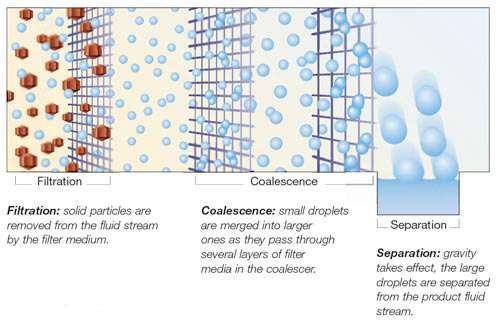

Pall’s coalescers effectively filter in three stages:

- Filtration – Solid contaminants increase the stability of an emulsion and reduce its efficiency. Pall’s coalescers remove solids utilizing a cartridge filter and preconditions the fluid for optimum coalescer performance.

- Coalescence – A high-performance coalescer medium captures the droplets that are to be separated from the bulk fluid. These droplets move through a coalescing media with progressively larger pores and are coalesced to form larger droplets.

- Separation – The droplets are released from the coalescing media; the phases are separated by either gravity in the settling zone or by coalescing filter separators.

In normal glass fiber coalescers, the surfactants ‘coat’ the medium's surface, leading to disarming that reduces separation efficiency by decreasing the medium's coalescing properties. Pall’s coalescent filter material consists of polymeric media that is free from glass fibers and is less prone to disarming in the presence of surfactants. This property enables it to offer a longer life compared to other glass fiber coalescers.

Why should you choose Pall’s coalescers?

Pall’s coalescing filters provide several benefits, like:

- Improved fluid quality, consistency, and value

- Lower separation costs

- Lower operating, disposal, and maintenance costs

- Reduced costly corrosion problems in downstream equipment

- Prevention of catalyst deactivation in downstream processes

- Eliminating the need for emulsion breaking chemicals

- Prevention of disarming, thereby increasing service life

- Elimination of ongoing labor costs to change disarmed glass fiber coalescer elements or mesh packs

- Extended time between scheduled maintenance periods

- High-performance design for smaller assembly size

- Improved availability

Pall offers a wide range of coalescer:

Liquid/Liquid Coalescers

Pall's Liquid/Liquid Coalescer separator can efficiently separate liquid-liquid emulsions in oil, gas, and chemical industries. It helps businesses with extended equipment life, reliable operations, and reduced overall cost to offer products that comply with specifications. The Liquid/Liquid Coalescer uses high-efficiency separation with a polymeric material to break emulsion into two phases. The coalescer element can take care of very low interfacial tension (IFT) and doesn't disarm with surfactants.

1) PhaseSep® Coalescers

Pall's PhaseSep coalescing filter can virtually separate any liquid-liquid emulsion.

2) AquaSep® Coalescers

Pall's AquaSep coalescer effectively separates water from the hydrocarbon stream at lower cost.

Specifically designed for critical air or gas service applications, Pall Liquid/Gas Coalescers filters offer high-efficiency removal of water or oil droplets and particulate solids.

The coalescing filters capture the droplets using a series of graded non-wettable media and coalesce and drain them to the bottom of the housing. They prevent re-entrainment of the filtered droplet into the downstream gas flow.

Pall’s Liquid/Gas Coalescers filters protect downstream equipment and processes from water, compressor wear products, lubrication oil, or other liquid droplets, corrosion products, and other particulate contaminants and reduce maintenance costs.

1) SepraSol™ Coalescers

Pall’s SepraSol coalescers provide high-efficiency liquid and solid removal from contaminated gases, reducing maintenance and operating costs. A patented chemical surface treatment enhances the drainage properties of coalescer element, leading to improved performance allowing for smaller systems, lower pressure drop, and improved ability to recover from liquid slugs.

2) SepraSol™ Plus Coalescers

The SepraSol Plus media can process several times more liquid per unit area of media than conventional media and often eliminates the need for upstream bulk separation equipment like mist eliminators and vane separators.

The SepraSol Plus media is supplied in a large flow, high-performance 6-inch diameter cartridge that can economically treat large gas flows in applications that require a high degree of protection from both solids and liquids.

3) Medallion™ Coalescers

Pall’s Medallion coalescers is designed to offer enhanced process performance by providing reduced operation and maintenance costs.