WS10 Series Water Sensor

For Measurement of Water Content in Oil

The Pall WS10 Series water sensor is an ideal, low-cost, in-line, monitoring solution for measuring dissolved water content in hydraulic, lubricating and insulating fluids. Specifically designed for use in harsh and often remote industrial environments, readings are transmitted continuously to the user's control systems as a key component in the predictive maintenance of plant and machinery.Features

- A sensing probe directly immersed in the fluid to monitor dissolved water content and temperature

- Water content output in % saturation

- Temperature in °C or °F

- High pressure option up to 100 bar (1450 psi)

- Simple and flexible installation, simple to operate

- Robust all in-one modular housing and sensing probe design

- Two analogue outputs, 4 - 20 mA, for connections to existing SCADA and DCS systems

The Effect of Water in Oil

Water contamination in fluids can cause numerous problems such as additive depletion, oil oxidation, corrosion, reduced lubricating film thickness, microbial growth, and reduction of dielectric strength. These costly problems can be averted with continuous monitoring of oil water content so that timely action can be implemented.Hydraulic, lubricating and insulating fluids should be operated without the presence of free water and with dissolved water levels at 50 % saturation or considerably lower in the case of insulating oils.

Water Content Measurement in Oil

PPM

The common industry practice has been to report water content in oil in terms of parts per million (PPM). Most fluids can tolerate a certain degree of water contamination, but at what level is it considered excessive? 200 PPM of water in a phosphate ester based oil would be excellent. However, the same amount would be catastrophic in a transformer oil.% Saturation

An alternate way to report water content is as a percentage of the water saturation level of the fluid for a given temperature. One advantage of this method is that it provides a better measure of how close the water content is to the water saturation level of the oil and hence, the formation of free water in the fluid. The WS10 water sensor reports the presence of dissolved water in oil in the range of 0 % to 100 % of saturation. If an oil is cloudy due to free water contamination at the measurement temperature, the WS10 Water Sensor will display 100 % saturation, until steps are taken to bring the water content below the saturation point.Simple Installation

The Water Sensor enclosure is designed in modular form for safe and convenient installation. The M12 connector allows for electrical wiring of the Water Sensor for power and sensor output. Each section of the enclosure fits securely to achieve at least IP65 (NEMA 4) moisture protection rating.| Supply Voltage | 21-28 VDC (requires ≥ 200 mA)) |

| Working Temperature Range | |

| Sensing Probe | - 40 °C to 125 °C (-40 °F to 275 °F) |

| Electronics | - 40 °C to 80 °C (-40 °F to 176 °F) |

| Fluid Compatibility | Petroleum based and synthetic fluids. The water sensor is not to be used in water based fluids or aerospace phosphate ester hydraulic fluids. |

| Pressure Range | |

| Standard Model | Up to 20 bar (290 psi) |

| High Pressure Model | Up to 100 bar (1450 psi) |

| Probe Connector | 1⁄2 in. NPT (male) or 1⁄2 in. BSPP (male) |

| Electrical Connector | M12 - included in scope of supply |

| Accuracy | |

| Humidity Sensor | ± 2 % 0 to 90 % RH and ± 3 % 90 to 100 % Traceable to international standards, administered by NIST, PTB, BEV |

| Temperature Sensor | Pt 1000 (Tolerance Class A, DIN EN60751) |

| Enclosure | IP65 (NEMA 4) |

| Weight | 0.43 kg (0.95 lb) |

| Calibration Services | Available from Pall; contact your local representative |

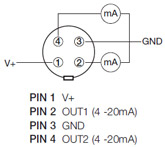

| Outputs | 4-20 mA Load < 500 Ohm OUT 1 = 0 to 100 % RH OUT 2 = -25 to 125 °C (-13 to 257 °F) |

M12 Connector Configuration

(IEC 61076-2-101)

There are numerous applications for the WS10 Water sensor, including:

- Primary Metals

Rod Mill High Speed Lube Systems

Cold Mill Tandem Mill

Tilt Furnace HPU's - Power Generation

Wind Turbine Gear Box Lube

Main Turbine Lube Oil

Transformer Oil - Pulp and Paper

Dryer Section Lube Systems

Wet End Lube Systems

Press Section Hyd/Lube Systems

Powerhouse - Steam Turbine Lube Systems - Marine

Main propulsion lubrication

Hydraulic active fin stabilization - Industrial In-plant

- Automotive

- Offshore / Petrochemicals

Diagnostic and Monitoring Equipment

Testing, Monitoring

Water Sensor P/N: WS10 S [1] [2]

Table 1: Relay Options

| Code | Probe Options |

| B08 | 1⁄2 NPT connector |

| C08 | 1⁄2 BSPP connector |

Table 2: Probe Options

| Code | Pressure Options |

| None | 20 bar (290 psi) Standard |

| H | 100 bar (1450 psi) High Pressure |

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.