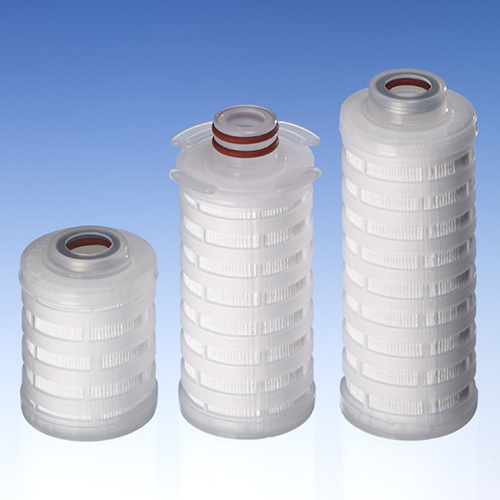

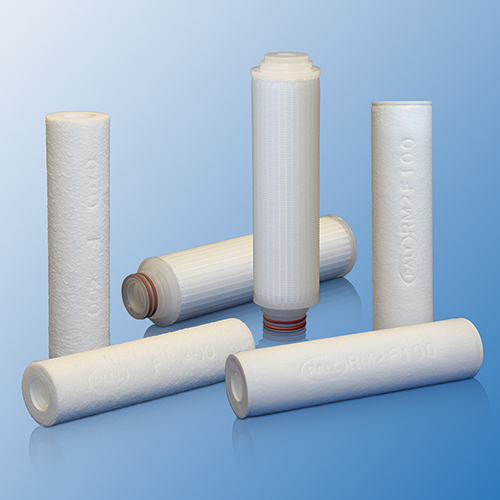

Developed from traditional depth filtration technology, SUPRApak modules efficiently combine the filtration mechanisms of surface filtration, depth filtration and adsorption. Highly unique to their design is an entirely new flow configuration, based on the “edge flow” principle.

Filter sheet material is wrapped around a central, permeable core. Feed and filtrate channels provide a fluid flow path resulting in maximum utilization of the sheet material, to provide highly efficient contaminant removal and a cost-effective closed system alternative to flat sheet filtration.

SH series SUPRApak modules are constructed from Seitz® IR Series filter sheets which undergo a proprietary treatment that results in extremely low levels of extractable ions. This makes them ideal for spirits applications since ions like calcium and magnesium can result in precipitation and haze formation.

| Features |

Benefits |

Flow configuration based on "edge flow" principle |

- Higher throughput compared to classical sheet filtration1

- Increased adsorption capability and excellent filtrate quality

|

| Closed filtration system |

- Increased process safety and product quality; no drip losses; reduction in volatile organic compounds

|

| Drainable, low hold-up volume assembly |

- Higher product yield; lower cleaning costs

|

| Constructed from ion reduced filter sheets (calcium, iron, magnesium and aluminium) |

- Reduced risk of precipitation in distilled spirits

|

| High filtration capacity in compact design |

|

| Simple, quick installation and servicing |

- Reduced labor and maintenance costs

|

1 Depending on application and product selection

Quality

- Filter sheets produced in a controlled environment

- Manufactured according to ISO 9001:2015 certified Quality Management System

Food Contact Compliance

Please refer to the Pall website www.pall.com/foodandbev for a Declaration of Compliance to specific National Legislation and/or Regional Regulatory requirements for food contact use.