Applications and Uses:

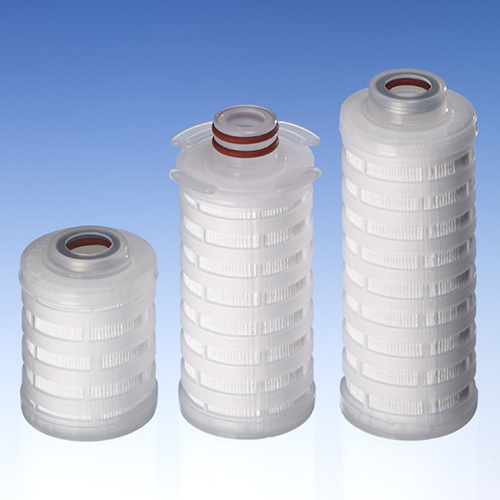

SUPRAdisc II Modules

- Polishing filtration: Wine, beer, juice, sugar syrups and thick liquor gelatin

- Microorganism reduction & yeast removal: Wine, sugar syrups and enzyme solutions

- Coarse filtration: Wine, fruit juice, tea-based beverages, olive oil and thin liquor gelatin

Other uses include: Pre-clarification, clarification, particle filtration, fine filtration, chill haze removal and stabilization and colloidal removal.

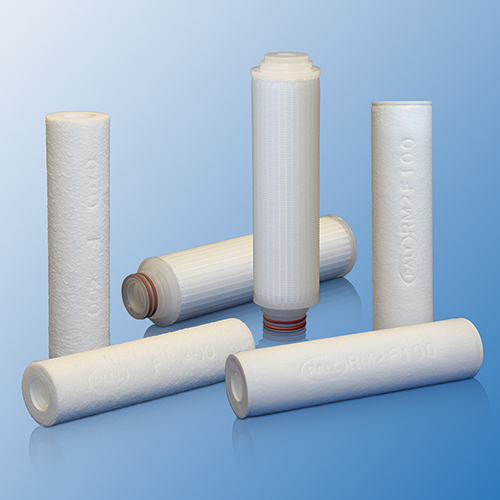

SUPRApak Modules

- Clarifying filtration: Beer, wine, fruit juice, flavors and thin liquor gelatin

- Coarse particle removal: Wax removal in edible oils and cannabis oil

- Polishing filtration: Flavors and white spirits, all liquid foods and beverages

- Chill filtration: Brown spirits or white spirits high in fatty acids

- Fine filtration: All liquid foods and beverages

- Final filtration: Sugar solutions, fructooligosaccharides and enzyme solutions

Other uses include: Pre-clarification, clarification, particle filtration, stabilization and colloidal removal.

SUPRApak PLUS Modules

- Final filtration: Enzyme solutions, sweeteners

- Polishing filtration: Sweeteners, beer, wine, flavors, thin liquor gelatin, yeast extract and vinegar

- Clarifying filtration: Beer, wine, enzymes, flavors, thin liquor gelatin, polyols and edible oils

- Coarse filtration: General particle removal

SUPRAdisc AKS 4 Modules

- Dechlorination of water

- Correction of off color, flavor and odors in distilled spirits, wine and beer

- Decolorization of sweetener and sugar syrups

- Color correction in juice and beer applications

- Gelatin decolorization and deodorization

SUPRAdisc AKS FB modules

- Regulatory compliance (e.g., FCC, O.I.V)

- Correction of color, flavor and odors in distilled spirits

- Color removal in cannabis

- Color removal in hard seltzer

- Decolorization of sweetener and sugar syrups

- Color correction in juice and beer applications

- Dechlorination of water

- Gelatin decolorization and deodorization