Recovering Higher Value Wine and Juice from Lees

Recovery of wine and juice from lees represents one of the most challenging forms of filtration faced by wineries. The high concentration and variability of the suspended solids limits the suitable filtration technologies, while strict environmental regulations and sustainability programs are increasing pressure to reduce waste volumes. The Oenoflow HS system is a new crossflow filtration system designed specifically for lees processing. The hollow fiber membrane system overcomes the typical drawbacks associated with the existing Diatomaceous Earth (DE) based lees filters, producing higher quality product more efficiently and economically.The Lees Challenge

Lees, the sediment at the bottom of juice, fermentation or fining vessels, can represent up to 10% of a winery’s total volume. With solids concentrations typically in the range of 20 –30%, lees still contains a high percentage of recoverable product.Traditionally, lees filtration is performed with DE based filtration systems like rotary vacuum drum (RVD) or chamber press filters. While these systems can handle high solids, the open design allows for oxygen pick up which can affect quality. Recovered wine often needs further processing, and is typically downgraded in value and used in blends instead of added back to the original batch. In many small and mid size wineries, the lees volume from a single batch is often too small for processing with an RVD. In such cases the wineries will delay processing the lees and wait to accumulate an appropriate volume, hence the potential to recover high value product is lost.

DE based technologies can also require large volumes of filter aid. This increases the winery waste, disposal, labor, and losses; all factors contributing to high operating costs.

Oenoflow HS System Benefits

The higher value of the recovered wine and juice combined with the operating benefits make the Oenoflow HS system a reliable and economical replacement for the traditional RVD or chamber press filters.| Feature | Benefit | Value |

| Three applications in one system |

|

|

| No filter aid requirement (DE |

|

|

| Enclosed system design |

|

|

| Low hold-up volume |

|

|

| Bottom to top module flow path |

|

|

| PVDF membranes |

|

|

| Wide bore hollow fibers |

|

|

| Flexible software with fully automated working cycles |

|

|

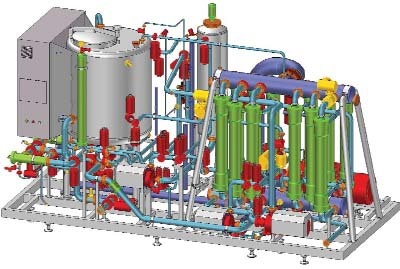

Oenoflow HS System Range

The Oenoflow HS systems are available in various sizes to meet the different needs and expectations of wineries around the world. The table below provides a guideline for the average flow rates over 4 to 6 hours of operation. Our wine specialists are available to help you select the appropriate system to meet your specific requirements.

Oenoflow HS-A

| Model | Number of Modules | Filter Area | Typical Lees Flow Rate | Typical Wine Flow Rate |

| HS-4A | 4 | 20 m2 | 400 - 800 lph (105 - 210 gph)) |

1000 - 1800 lph (265 - 475 gph) |

| HS-6A | 6 | 30 m2 | 600 - 1200 lph (158 - 317 gph) |

1500 - 2700 lph (396 - 713 gph) |

| HS-12A | 12 | 60 m2 | 1200 - 2400 lph (317 - 634 gph) |

3000 - 5400 lph (792 - 1427 gph) |

| HS-24A | 24 | 120 m2 | 2400 - 4800 lph (634 - 1268 gph) |

6000-12800 lph (1585 - 2853 gph) |

Quality and Maintenance

The Oenoflow HS systems utilize components with proven reliability from well-known industry accepted manufacturers. This allows for convenient supply of spare parts anywhere in the world.

Qualified Pall personnel are available to carry out scheduled maintenance or emergency service to ensure optimal use and up-time. Please contact your Pall representative for more details.

The Crossflow Solution

The Oenoflow HS system is a new crossflow filtration system for lees filtration that overcomes many of the obstacles associated with the traditional DE based technologies. Filtration is achieved with microporous membranes without the need for filter aids. With no powder handling, operation is more hygienic and does not create DE waste for environmental landfill.Wide bore hollow fibers permit processing of lees with high solids levels. A high yield product can be recovered as the retained solids reach final concentrations up to 80%. The polyvinylidene difluoride (PVDF) membranes have a uniform structure that guarantees resistance to abrasion and high flow rates without compromising reliability even with repeated cleaning regimes.

The low system hold up volume and batch operating mode allows small volumes of lees to be filtered immediately after racking in order to maintain optimal quality in the recovered product.

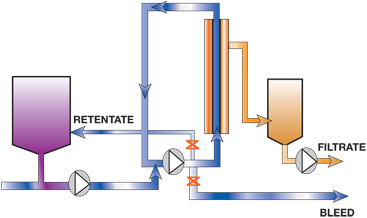

Oenoflow HS flow path

Figure 1: Oenoflow HS flow path

Three Systems in One

1. Recovery of wine from lees

2. Recovery of juice from must lees

3. Post fermentation clarification

1. The base Oenoflow HS system can be used to recover wine from lees. Recovered wine passes through the membranes and the suspended solids are retained upstream in the crossflow loop. See Figure 1.

2. For must lees processing during harvest, a pre-treatment screen can be added upstream of the base hollow fiber system to extend run time.

3. When the Oenoflow HS system is not processing lees, it can be used for standard post fermentation wine clarification to increase cellar capacity. The systems have a simple touch screen interface where the operator can select wine or lees filtration in order to optimize the filtration settings according to the application. See Figure 3.

Figure 2: Oenoscreen rotary sieve ilter added upstream

Figure 3: Touch screen interface

Recovering Higher Value Product

In addition to the operational and environmental benefits, the Oenoflow HS system also provides significant product quality benefits. Unlike the open DE systems, the enclosed system minimizes oxygen pick up and maintains the color, aroma, acidity and flavor characteristics. The microfiltration membranes provide consistent filtrate quality with typical turbidity less than 1 NTU (see Figure 4)Recovered juice can be combined with must prior to fermentation. Recovered wine can be added back to the original batch at a significantly higher value than the wine recovered from RVD and chamber filters which is often blended into lower quality, lower priced wines. This added value is reflected in short system return on investment with typical payback in the range of 1 to 3 years.

Figure 4: Lees before filtration (left), and recovered wine after filtration (right)

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.