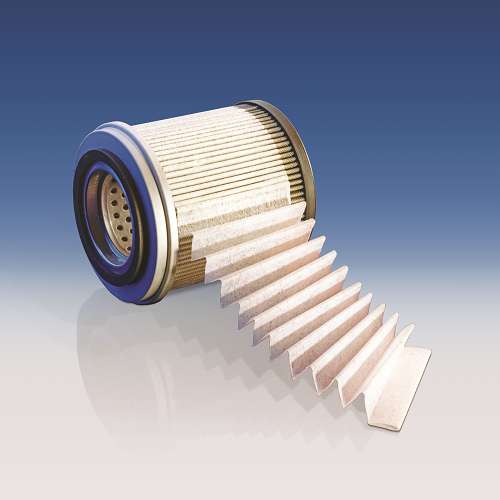

A laid-over pleat geometry which offers improved performance and a reduction in filtration operating costs.

- Longer filter element service life

- Up to 50% smaller and lighter

- OEM approved

Why do Ultipleat elements have lower operating costs?

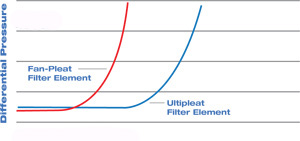

Long Service LifeThe unique, laid-over pleat geometry provides a greater filtration area than conventional ‘fan-pleat’ filter elements for the same envelope. This, coupled with a more uniform flow distribution results in a significant increase in dirt holding capacity when compared to a fan (radial) pleat construction in the same space envelope.

Side by side comparison testing has shown

Up to 50% more dirt capacity for Ultipleat compared to conventional fan pleat

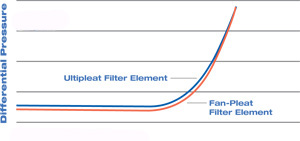

Alternatively, the larger filtration area can be used to design an Ultipleat filter element with a finer micron rating and the same service life compared to a fan-pleat design in the same space envelope.

Low weight and space requirements

Ultipleat elements have a lower flow density, and consequently, a higher flow capacity. As a result, filter size can be reduced substantially. The smaller size combined with polymeric support meshes reduces weight by as much as 50%.

The higher dirt capacity(service life) for the same envelope can be traded off for a smaller envelope with the same dirt capacity as the conventional radial pleat filter element. In addition, the use of polymeric support meshes can also lead to a substantial reduction in filter element weight.

A low average pressure drop is important for keeping energy consumption to a minimum. This allows more flow through the filter during low temperature, high viscosity start-up conditions.

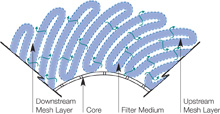

Stability of performanceThe pleats are supported both upstream and downstream which helps to maintain efficiency and performance during cyclic flow or cyclic pressure(pump ripple) conditions.

Why do Ultipleat elements have a uniform flow distribution?

|

|

|

Conventional pleated filter element construction, showing Non-uniform flow distribution (Outside to Inside flow direction).In a conventional filter element the pleats radiate outward from the core and the spacing between the pleats increases. This space represents wasted volume and unused filtration area. |

Ultipleat filter element construction showing uniform flow distribution (Outside to Inside flow direction).

|

Why do some engines use a reverse-flow filter element?

In a reverse-flow Ultipleat design, the fluid flows from Inside to Outside and all the contaminants are retained inside the filter element. This concept offers several benefits:

- Weight saving - structural core can be integrated into the filter bowl

- Simpler maintenance - no need to clean filter bowl

- Less chance of cross-contamination during filter element change out

- Engine Lube

- Engine Fuel

- Hydraulic

- Helicopter Transmissions

- Liquid Cooling

|

|

|

Literature and Other Resources

Aerospace Ultipleat Data sheet

Optimizing Filter Element Design for Size, Weight and Life Improvements, Paper No. IFC10-002

Our filter elements are designed and tailored to meet the customer specification requirements.

If you have an aerospace application that needs an Ultipleat laid-over pleat design, please talk to one of our experts Contact Aerospace

For commercial aircraft products, please contact our authorised distributor, Satair

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.