Order Products

Availability

In Stock

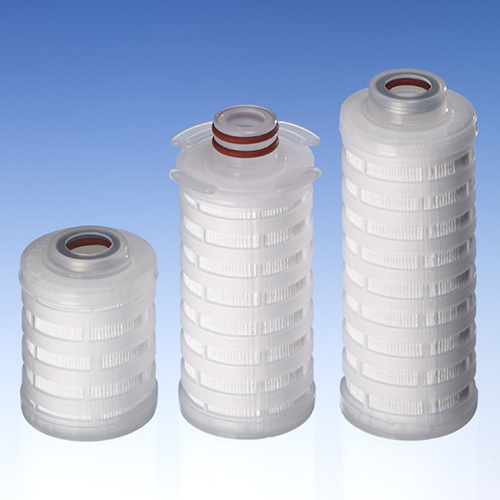

Fluorodyne® II DFL membrane in Kleenpak™ capsule, 0.2 µm sterilizing grade, 800 cm² EFA, 1½ in. sanitary flange inlet and ½ in. hose barb outlet connections, pre-sterilized by gamma irradiation

1/EA

1

Emflon® PFRW Kleenpak™ Capsules, 0.2µm, 174 mm,

1/EA

1

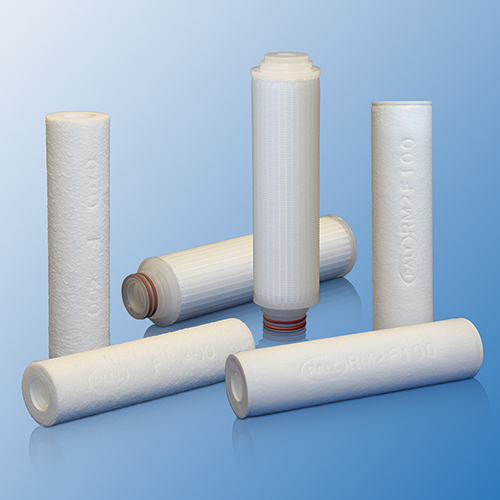

Emflon® PFRW Junior Style Filter Cartridge, 0.2µm, 5.3 in, Internal Plug seal with single 116 Silicone Elastomer O-ring

1/EA

1

Profile® II Filter Cartridges, 0.5 µm, 40 in, Single Open Ended Code 7, Silicone Elastomer O-ring

1/EA

1

Nexis, NXA, 0.5 μm, 76.2 cm (30 in), SOE flat closed end, external 222 O-rings (retrofits other manufacturers’ Code 0), Silicone gasket

12/EA

12

0.5um, 20", DOE

12/EA

12

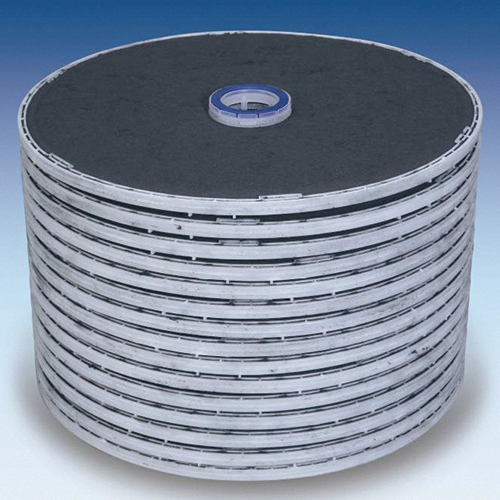

SUPRAdisc SD II 080 200X080C232SPW

1/EA

1

Vector, polypropylene Media Material with 1 µm (micron) Filter Grade

4/EA

4

SUPRAdisc SD II EK 1 200XEK1C232SPW

1/EA

1

SUPRAdisc 1 Lenticular, 12", Flat Gasket, Silicone Seal, Seitz AKS 4 media, 1,7 m² Filter Area

1/EA

1